How Barcodes & Honeywell Technology Helped Transform Warehouse Operations

Transforming warehouse operations with barcode technology increases efficiency, throughput, and cost-effectiveness. However, businesses that have always relied on manual processes may need to learn the steps to ensure their tech investments lead to value and ROI. Barcodes, Inc. provides the guidance and expertise necessary for successful warehouse transformation.

The project at Monat Global Corp. is an excellent example of how proper barcode technology implementation can improve operations and position a business for greater success. This direct sales haircare, skincare, and wellness product company was 100% manual, even relying on employees to build boxes. However, putaway and picking were also manual. Employees memorized product locations in the warehouse and jotted down the quantities they needed to fill orders, an inefficient and sometimes error-prone process.

Steps to Warehouse Transformation

Barcodes, Inc. and its partner Alpine Supply Chain Solutions worked with Monat to implement barcode technology with dramatic results.

Step one was creating a naming structure that worked with Monat’s SAP Extended Warehouse Management (EWM) system.

Then Barcodes, Inc. generated labels in batches for warehouse racking so Monat could save time and apply the labels systematically.

With labels in place, Monat relied on Barcodes, Inc.’s expertise to test mobile devices and barcode scanners to select the best options for the warehouse. Monat chose Honeywell CK65 mobile devices and Granit XP 1990iXR corded scanners. The solution also included Honeywell vehicle-mounted computers and industrial printers.

The technology allowed Monat’s team to no longer memorize product locations or depend on handwritten notes. They now use modern processes, such as directed putaway, triggered replenishment, and triggered case picking.

See Monat’s Digital Transformation in Action

The Advantages of a Modern Warehouse with Barcode Technology

Monat monitored key performance indicators before and after the transition and found that using barcode technology significantly impacted its overall operation. Monat’s warehouse increased from 80 to 260 lines per hour and from 20 to 60 orders per hour, tripling throughput.

The company also saw a vast improvement in order accuracy and decreased the time necessary to train new employees to work independently from days to just an hour.

Download our case study to learn more about the Honeywell technology that made this successful transition to a modern warehouse possible.

Janam XG3 Improves Productivity by 20%

American Nutrition Implements Barcode Scanning & Mobile Computing Solution that Markedly Increases Productivity and Efficiency

Application: Barcode Scanning & Mobile Computing Solution

Executive Summary

American Nutrition, a leading manufacturer of pet food and treats for branded companies and retailers. In search to simplify their workflow, they want to find a warehouse management solution (WMS) to track their products across their three facilities . Barcodes identified an optimal barcode scanning and mobile computing solution, the Janam XG3-ER rugged mobile computer, that provided a solution to connect their existing lot tracking, process control, and shipping software under one management platform. By utilizing the Janam XG-ER our customers increased visibility into inventory and process control, enhanced employee productivity, and run their proprietary WMS on an Android operating system.

The Business Challenge

Warehouse employees need access to secure information right away. The current method of relying on their memory to keep track of the products’ physical location in the warehouse was not working. It was taking workers too long to access the data they needed to perform their jobs effectively and efficiently. There were also issues with the human memory error that slowed down processes. To address these concerns, American Nutrition would need to invest in a barcode scanning and mobile computing solution capable of providing workers with inventory and product information in real time. They needed solution that can scan pallets stored on top level racks, accept both touch screen data and keyed data, as well as have an open operating system to future proof their business. Investing in this solution would allow the manufacturer employees to work more efficiently and eliminate the human error associated with memorizing product and inventory information.

Solution

Barcodes recommended the Janam XG3 Rugged Mobile Computer. The Janam XG3 provides a warehouse ready rugged mobile scanner, with a scan range of 15 inches to 50 feet, touch screen and 57-key keypad for data entry. In addition, the XG3 has the ability to run their proprietary WMS on an Android operating system. This allowed American Nutrition to manage and track all items in an effective and efficient manner and add a new layer of accountability to their process.

Benefits

Barcodes deployed forty-five Janam XG3s in three US facilities in a short amount of time. American Nutrition’s business expectations continue to be met and exceeded. Not only do employees know where all their inventory is from receiving raw goods to shipping finished product, but they have seen measurable increases in productivity and efficiency. In addition, they have eliminated the human error associated with memorizing inventory information.

Contact Barcodes, if you have any questions or need a warehouse solution. We can find a solution that fits your business needs and budget.

Janam’s XT2 Brings High Performance to CJ Pony Parts

CJ Pony Parts is one of the oldest Mustang parts retailers in the world. Founded in 1985 to friends with a passion for classic Ford mustangs, the company began by stocking and selling parts for every Mustang model since Pony Car was introduced in 1964. With more than 63,000 square feet of warehouse space across three facilities, CJ Pony Parts houses more than 50,000 parts and accessories.

With so many parts over the four warehouses, the challenge was to find a newer and more intuitive rugged barcode scanner for their daily operation to improve productivity and increase efficiency. With 60 XT2 mobile computers deployed throughout their four facilities, the devices were quickly adapted by their workforce to increase productivity and improved customer service. Click to read the following case study to see how Barcodes recommended the Janam’s XT2 Rugged touch mobile computer to CJ’s Pony Parts and successfully implemented the devices to provide visibility across all its warehouse operations.

A Warehouse Robotics Company Implements iPad Mini & Powerful Barcode Scanning Solution

Executive Summary

Executive Summary

A warehouse robotics manufacturing company was in search of a user interface to complete and enhance their robots. A powerful barcode scanning solution with a strong and durable scan engine was required to improve processes. Additionally, it needed to be compatible with the iPad Mini due to their workers familiarity with the product and integration with their existing enterprise software.

Barcodes identified an optimal barcode scanning solution that not only streamlined processes but also increased the revenue stream for a robotics company’s clients.

The Business Challenge

The robots created by the robotics company are used at their customer’s facilities. A technologically advanced solution was required to allow warehouse associates the ability to interact directly with the robots for order picking, inventory control, and efficiency measures. They need a simple and lightweight solution to implement various warehouse management applications.

Solution

Barcodes recommended the Infinite Peripherals Infinea Tabâ„¢ M and case (CS-TAL) with 1D/2D barcode scanner, along with the Apple iPad Mini. This allowed mobile employees to convert the Apple iPad Mini into a powerful warehouse management and scanning solution to fulfill their operational needs. The Infinea Tabâ„¢ M has a 2D imager scan engine which reads the most widely used 1D and 2D barcodes that has made it the ideal solution for order picking and inventory control.

Benefits

Having implemented the solution, the warehouse robotics company has seen the benefits of using an iPad mini and powerful scanning solution in one. The intuitive user interface on the Infinea Tabâ„¢ M has led to increased productivity by the end users, which has allowed more orders to ship; thus, revenue to increase for their customers.

The warehouse robotics company has scaled widely once their robots were delivered and implemented at each of their customer’s site. Not only through word of mouth, but through various trade shows, the interest in the robots and the technology used within the robots has set the company on a path for tremendous growth with the help of Barcodes.

U.S. Pet Food Manufacturer Implements Barcode Scanning & Mobile Computing Solution that Increases Productivity & Efficiency by 25%

Executive Summary

Executive Summary

A large pet food manufacturer was in search for a warehouse management solution (WMS) to keep track of their product across their three US facilities and increase visibility into their inventory and process control. They were looking for a solution that could connect their existing lot tracking, process control, and shipping software together under one warehouse management umbrella. Barcodes identified an optimal barcode scanning and mobile computing solution that provided increased visibility into their inventory and process control, enhanced employee productivity and had the aptitude to run their proprietary WMS on an Android operating system. This allowed the pet food manufacturer to streamline their processes and add a layer of accountability to their methods.

The Business Challenge

Warehouse employees need access to secure information right away. The current method of relying on their memory to keep track of the products’ physical location in the warehouse was not working. It was taking workers too long to access the data they needed to perform their jobs effectively and efficiently. There were also issues with the human memory error that slowed down processes. To address these concerns, the pet food manufacturer would need to invest in a barcode scanning and mobile computing solution capable of providing workers with inventory and product information in real time. They needed a solution that can scan pallets stored on top level racks, accept both touchscreen data and keyed data, as well as have an open operating system to future proof their business. Investing in this solution would allow the manufacturer employees to work more efficiently and eliminate the human error associated with memorizing product and inventory information.

Solution

Barcodes recommended the Janam XG3 Rugged Mobile Computer. The Janam XG3 provides a warehouse ready rugged mobile scanner, with a scan range of 15 inches to 50 feet, touchscreen and 57-key keypad for data entry. In addition, the XG3 has the ability to run their proprietary WMS on an Android operating system. This allowed the pet food manufacturer to manage and track all items in an effective and efficient manner and add a new layer of accountability to their process.

Benefits

Barcodes deployed forty-five Janam XG3s in three US facilities in a short amount of time. The pet food manufacturer’s business expectations continue to be met and exceeded. Not only do employees know where all their inventory is, from receiving raw goods to shipping finished product, but they have seen an increase in productivity and efficiency by 25%. In addition, they have eliminated the human error associated with memorizing inventory information.

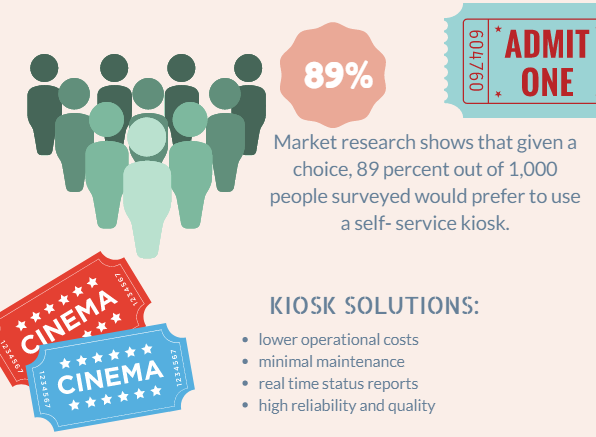

Star’s SK1-21 Kiosk Printer: Improve Your Cinema Experience

Besides the movie that you are going to watch, the ticketing system are integral to the cinema experience as well. Kiosks can be used to purchase tickets, retrieve tickets bought online, and to place concession orders. This is especially important for movie goers who arrive with just a few minutes to spare. They can bypass the line to purchase tickets or snacks and still make it in time before the movie starts.

To make sure your cinema kiosk is reaching its full potential by considering these 4 things:

1. Your Kiosk should support a thermal printer– A cinema kiosk should support a heavy duty thermal printer with a jam free system to produce tickets in the fastest way. Star’s SK1-21 Kiosk Printer two inch series provides dependable, maintenance- free printers that have a fast print speed of 200mm/ sec with 203 dpi resolution. All SK-21 models will intergrate with many commonly used kiosk solutions. It provides high speed, reliability, and will integrate in your kiosk seamlessly.

2. Barcode Scanner- Movie theaters often offer their own loyalty program to keep the customers returning back. Your customers love freebies and accruing points towards free movie tickets, so don’t keep them waiting on the full service line to rack up the points.

3. Integrated Speakers- Talk to the customer through the ticket buying process. This is important for those who aren’t familiar with the self-service kiosks check out.

4. Card Payment Acceptance- Not everyone carries cash, so make sure that your kiosk is equipped with a card reader and payment processing platform.

Check out the video below on a successful self service kiosk integration at Nitehawk Cinema.

For any questions or a quote on any of your printing needs contact us at Barcodes, Inc.

A Royal Point of Sale System

Challenge

Royal Caribbean International is known for driving innovation at sea and has continuously redefined cruise vacationing since its launch in 1969. Each successive class of ships is an architectural marvel and pushes the envelope of what is possible on a cruise ship. Onboard, the global cruise line has debuted countless industry “firsts†– such as rock climbing, ice skating and surfing at sea – to capture the imagination of families and adventurous vacationers alike. Throughout, guests sail on exciting itineraries to some of the world’s most popular destinations and enjoy Royal Caribbean’s friendly and engaging service.

While delivering innovative entertainment onboard their luxury cruise ships, they required their various restaurants, shops, and bars to process point of sale payments for their customers looking to indulge in food, entertainment, and shopping. They wanted to deliver a quick, seamless and positive point of sale experience for their customers.

Analysis

Royal Caribbean sought a point of sale hardware system that would meet their customer experience demands and be compatible with their point of sale software solution. They sought a bundle that included receipt printers, touchscreens, and barcode scanners for their various restaurants, shops and entertainment facilities. Additionally, they wanted a kitchen receipt printer to meet the demanding requirements of a busy restaurant without sacrificing performance.

Solution

To provide an appropriate solution, Barcodes, Inc. worked closely with Royal Caribbean to test the compatibility between the hardware and software. Barcodes selected the Epson TM-T88V, an industry-leading point of sale receipt printer that offers fast printing, best-in-class reliability, and ease-of-use features. The TM-T88V is also ENERGY STAR qualified and offers print options that reduce paper usage up to 30 percent. Combined with the ELO 1523L touchscreen monitor and Zebra DS4308 barcode scanner, it was the ideal point of sale hardware bundle that Royal Caribbean required to run their point of sale operations effectively.

For the restaurant setting, Barcodes recommended the Epson TM-U220B, a high-speed throughput kitchen receipt printer that allowed customer receipts and kitchen orders to print faster than any other device. The TM- U220B comes equipped with an auto-cutter, which slices a clean edge, leaving a small portion of the receipt uncut so that they are still barely attached – ideal for printing duplicate receipts such as credit card receipts or gift receipts.Â

Results

The point of sale system that was delivered by Barcodes was easily deployed to the 40+ cruise ships and easily adopted by the employees aboard each of these ships.

Since purchasing the point of sale systems from Barcodes, Inc., Royal Caribbean has seen an uptick in productivity, quicker turnaround times on sales and kitchen orders, and a decrease in wait times for customers in line.

Royal Caribbean now has the peace of mind that every point of sale experience is first-class and can keep the line moving in order to increase revenue streams while keeping their customers happy.

For all of your point of sale needs, contact Barcodes, Inc. at 1-800-351-9962.

Zebra’s 2017 Manufacturing Vision Study

Zebra Technologies commission a global study to analyze trends and challenges that impact manufacturing companies. The survey asked 1,100 executives from automotive, high tech, food, beverage, tobacco, and pharmaceutical companies for their insights on adopting technology on the plant floor to increase their competitive position. The study includes the benefits of having IIoT, RFID, and Asset Management on a plant floor. Â To read more about the results of the study click the link below.

Zebra Technologies commission a global study to analyze trends and challenges that impact manufacturing companies. The survey asked 1,100 executives from automotive, high tech, food, beverage, tobacco, and pharmaceutical companies for their insights on adopting technology on the plant floor to increase their competitive position. The study includes the benefits of having IIoT, RFID, and Asset Management on a plant floor. Â To read more about the results of the study click the link below.

For further information visit www.zebra.com/manufacturing

Barcodes, Inc. Delivers and Astute Solution

Challenge

Challenge

Astute Medical manufactures biomarkers that are used to identify high-risk, acute medical conditions in critically ill patients. The Federal Drug Administration (FDA) issued a mandate that medical devices must carry a Unique Device Identifier (UDI), which requires a greater volume of information than had been previously required.

Astute Medical sought a compliance labeling solution that would meet UDI requirements in accordance with GS1 Standards. The manufacturer also wanted to receive accurate and repeatable verification results and a solution that included a Validation Protocol to document compliance with these requirements. We needed to not only comply with federal regulations, but also ensure that we were sending out our medical devices with a high-quality barcode, “to avoid returns,” explained Susan Shelton, Materials Management and Procurement Manager of Astute Medical.

Analysis

Astute Medical designs, engineers, and manufactures novel biomarkers that enable clinicians to identify acute conditions in their critically ill patients before the symptoms become evident. Products like the NephroCheck Test and Astute140 Meter fall under the guidelines of the FDA’s Unique Device Identification rule. This system was established to identify medical devices throughout their distribution and use, providing critical traceability that benefits the patient, caregiver, manufacturer, and distributor.

AirTrack S2 Helps County of Greenwood (SC) Sheriff Department’s Capture Data from Driver’s License in the Field

The County of Greenwood (South Carolina) Sheriff’s Department is to provide for the safety and protection of the citizens and businesses of Greenwood County through proven full service law enforcement practices, including both reactive and proactive responses to criminal activity, to ensure that public interests and constitutionally guaranteed liberties are protected and that the judicial process is followed according to law. In order to provide the best data to their patrol officers, they needed a way to scan a driver’s license and look up any associated records from out in the field.

The County of Greenwood (South Carolina) Sheriff’s Department is to provide for the safety and protection of the citizens and businesses of Greenwood County through proven full service law enforcement practices, including both reactive and proactive responses to criminal activity, to ensure that public interests and constitutionally guaranteed liberties are protected and that the judicial process is followed according to law. In order to provide the best data to their patrol officers, they needed a way to scan a driver’s license and look up any associated records from out in the field.

Barcodes, Inc. recommended the AirTrack S2 to scan the 2D barcodes off of driver’s licenses. The S2 is a fast, precise and nimble barcode scanner that offers omnidirectional reading and is rugged enough to withstand repeated drops from 5 feet to concrete. Since most driver’s licenses are equipped with both 1D and 2D barcodes, the S2 is ideal for its ability to read both symbologies. Additionally, the S2 can be configured to parse specific driver’s license information based on what data the patrol office wants to capture (i.e. name, driver’s license number, address, birthdate, etc.). The data is then parsed into the department’s software program to look up information on the individual, such as previous records, outstanding warrants, and other information. In order to protect their investment, the Sheriff’s department invested in AirTrack service contracts to protect their devices from defects and normal wear and tear.

To learn more about AirTrack, our Government solutions, or driver’s license parsing, contact one of our representatives.