For High-Performance RFID & Barcode Scanning, Look No Further than the Brady HH83 & HH85

Brady RFID Readers

Brady offers a range of RFID readers in a variety of form factors and configurations to ensure customers always have the right reader for their application. Equipped with powerful UHF RFID engines based on the latest technology, high-performance antennas, a unified API, and support for accessories, Brady RFID readers offer best-in-class performance and unparalleled flexibility.

Brady RFID readers support all common RFID use cases, including asset tracking, work in process tracking, inventory management, and vendor managed inventory.

Introducing the Brady HH83 and HH85 RFID/Barcode Scanners

Effective and user-friendly equipment, such as the Brady HH83 and/or Brady HH85, is critical in industrial settings. These exceptional RFID readers are both durable and rugged, yet also ergonomically designed and lightweight. For dependable and effortless operation throughout a long shift, look no further than the HH83 or HH85.

Both the HH83 and HH85 RFID readers are an invaluable tool for managing end-to-end data collection, with software-controllable RFID antennas, best-in-class scanning performance at ranges of up to 50 feet, and up to 18 hours of hot-swappable battery power. Here’s what you can expect from Brady scanners.

Key Features

- Single API for all devices

- Minimal software integration time

- Flexible and rapid software development with Android 10 and NUR API

- RFID and barcode scan range of up to 50 feet

- Work glove friendly touchscreen displays

- 5 foot drop protection

- Strategically placed trigger and buttons are easy to operate

- Rugged, durable construction with IP65 rating for dust, particle resistance

- Two year hardware warranty

- Responsive technical and customer support

For more technical details, download the HH83 HH85 spec sheet.

Watch a Demo of the HH85 RFID Reader

Enjoy high-performance RFID and barcode scanning with both the HH83 and/or HH85 from Brady. Contact us today to speak to an RFID expert who will help find the best solution for your organization.

Webinar: How to Automate Supply Chain Processes with RFID

About this Webinar

How to Automate Supply Chain Processes with RFID

Thursday, February 22 1:00 – 1:45pm CT

Presented by:

Tom O’Boyle, Principal RFID Solutions Architect, Levata

John Cooke, Director of Software Development, Smart Label Solutions (SLS)

Easily Scale RFID Technology with SLS Integration

RFID is revolutionizing shipping and receiving in a more scalable fashion than ever before. Purpose-built RFID solutions are improving order to delivery time and shipment accuracy across the supply chain while reducing labor intensive manual counting.

Watch this 30-minute webinar and discover the advantages of RFID for your organization:Â

- How to improve your supply chain visibility by automating your shipping and receiving functions using RFID through improved read accuracy to the item level and sub-second event alarming

- Why using professional grade software is an essential component of your RFID Solution, providing real-time visibility into the movement of assets and products, whether that be at a dock door, a tunnel or with a mobile device

- How RFID is easy to scale and deploy through rapid plug and play integration

Is Your Business Growing? Zebra Mobility Management Solutions Have You Covered

Your business is continually growing and changing. And that means that your business needs are constantly evolving. That’s why we’ve created mobility management solutions that grow with you. Whether you’re a medium-sized organization or a global corporation, Barcodes, Inc. has the mobility management solutions that will work best for your enterprise.

Mobility Management Solutions for Your Zebra Devices

When you partner with Barcodes’ for managed mobility solutions, we’ll help you scale up from tens to hundreds to thousands of devices—and as your needs change, we’ll make sure that your fleet stays up-to-date and reliable with the best selection of the newest Zebra technology.

Our managed mobility solutions include everything from new device set-up to routine maintenance so that as your company grows and changes, we’ll take care of managing the fleet of mobile devices you depend on to keep your operations running smoothly. We’re always here to help you with 24/7 support services from our team of experts who know your business from the inside out.

Zebra Technology for your Growing Business

Our comprehensive Zebra product portfolio offers a diverse selection of the latest Zebra technology to choose from, including rugged mobile devices, printers, software, barcode scanners, RFID solutions, and more. This wide range of products addresses a variety of customer requirements and offers complete solutions tailored to your unique needs.

Here are several Zebra products from Barcodes that are expertly designed for businesses of all sizes:

- ET40/ET45 Rugged Android Enterprise Tablets: Right price rugged tablets that have it all – right out of the box

- ET51 Rugged Enterprise Tablets with Integrated Scanner: Compact enterprise tablet with built-in scanning capabilities

- EC50/EC55 Enterprise Mobile Computers: Maximize personal productivity with a

smartphone-style device that is all business.

- TC72/TC77 Mobile Computers: A smartphone experience for maximum simplicity, designed to withstand years of the toughest use.

Get Growing with Custom Mobility Management Solutions

Barcodes can help you navigate the complex world of mobility solutions, saving you time and money along the way. Connect with us to learn more about how Barcodes’ Mobility Management Solutions can meet the unique mobility needs of your business. Get started today by contacting a Barcodes Mobility Expert online or calling us at (855) 233-2917.

How RFID Increases Shipment Accuracy

Webinar Details

How RFID Increases Shipment Accuracy

Thursday June 8th

1:00pm – 1:45pm Central

Presented By

Tom O’Boyle – Principal RFID Solutions Architect – Barcodes Group

Nat Hillary – Solutions Engineer for Strategic Accounts, Impinj

Why RFID?

Shipments sent to the wrong location, missing items, or containing the wrong items cost time, money and erode customer trust.

Placed on points of transition, RFID technology can identify thousands of items per second, and is capable of achieving a read accuracy above 99% percent.

And it delivers powerful insights into traffic patterns and service level metrics to further optimize your operations.

Discover the Advantages of RFID for Your Organization:

- Automate tracking of shipments moving in and out of dock doors without direct line-of-sight, reducing the need for human intervention and manual scanning

- Read tags on pallets, cases, or items

- Alert teams when a shipment is incomplete, contains the wrong items, or is loaded on the wrong truck

- Experience repeatability and scalability with an easy installation process (no matter the size of your business)

That means RFID tags placed on individual items, pallets, or containers will be read accurately to ensure that the right goods are on the right truck – every time.

Watch the Full RFID Webinar Recording

The How and Why of RAIN RFID Cryptographic Authentication

The problem of counterfeit products is global, and it’s growing. Knockoff handbags, athletic shoes, wristwatches, and pharmaceuticals cost businesses and consumers billions of dollars every year globally.

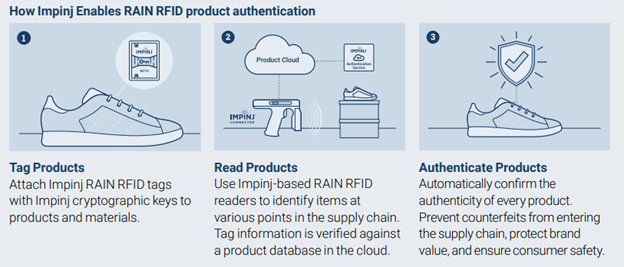

Now, there’s a new way brands can fight fakes: RAIN RFID cryptographic authentication.

The Impinj Authenticityâ„¢ solution engine brings enterprise-scale product authentication to new and existing RAIN RFID deployments.

What is Product Authentication?

At its heart, authenticating something is largely straightforward: You want to conclusively establish the item as genuine and determine its owner or origin. Doing that can get complex.

Product authentication solutions built on the Impinj platform employ secure cryptography, using a challenge-response protocol to determine with a high degree of certainty whether an item is genuine.

RAIN RFID from Impinj

An item tagged with RAIN RFID has certain information associated with it—data such as the manufacturer name, model number, serial number, date of manufacture, purchase date, customer name, and more. That item-specific data can be stored in a product cloud.

When that item is read at any point in the supply chain by a RAIN RFID reader, an Impinj-based authentication solution cross-checks and confirms the information stored in the product cloud and verifies the tag’s authenticity using the Impinj Authentication Service.

Impinj Authenticity uses cryptographic authentication, a feature of the new RFID tag chips, to swiftly and automatically verify tagged products as genuine.

Implement RAIN RFID with a Trusted Partner

For an in-depth explanation of how Impinj Authenticity works, contact Barcodes, Inc. to learn more about RAIN RFID.

RFID Webinar: Improve Returnable Container Tracking with RFID

Webinar

Improve Returnable Container Tracking with RFID

Thursday April 20th 1:00-1:45pm Central

PRESENTED BY:

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Michael Daily – Senior Solutions Engineer, Impinj

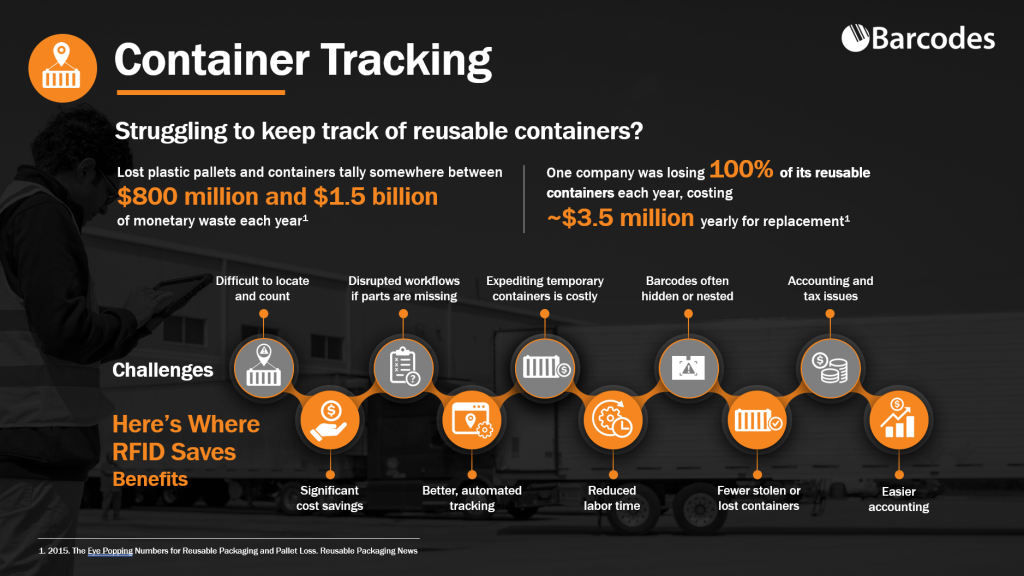

RFID-Based Container Tracking

Upon delivery, it’s common for reusable containers to not be returned to the sender, with annual shrinkage rates often exceeding 10%. Keeping track of your Returnable Transport Items (RTIs) can be challenging, especially when logging their location depends on manual processes like scanning.

In this webinar, discover the benefits of RFID-based container tracking:

- Reduce the number of misplaced pallets, kegs, and boxes. Less new delivery assets need to be purchased, and shipments are not interrupted due to lack of totes.

- Track each asset as it leaves and returns to the warehouse, allowing you to determine its exact location immediately and whether they have yet to return.

- Calculate the flow of returnable assets to fully understand your shipping capacity for the present and future.

- Improve utilization of workers since it takes way less time to scan RFID tags than barcodes, due to its fully automatable reading without line-of-sight requirements.

Watch the Full RFID Webinar Recording

Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.

Stages of a Successful RFID Deployment – Webinar

Webinar

Stages of a Successful RFID Deployment: From Discovery to Implementation

Thursday, October 27th, 2:00 PM – 2:30 PM ET

Presented By

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Nat Hillary – Solutions Engineer for Strategic Accounts, Impinj

About this RFID Webinar

Nearly 80% of attendees to our RFID webinars have not implemented the technology yet but are interested in exploring this. How do you determine if RFID is right for you and what steps are part of a deployment?

During this webinar, you will learn the answers to the following questions:

- Based on your unique needs, how do you determine if RFID can improve the flow of goods and inventory accuracy, and at what cost?

- Does RFID fit your organization considering your people, processes, and technology?

- How do you test reading RFID tags at your facility?

Watch the Full RFID Webinar Recording

Interested to learn more about our RFID deployment solutions and services? Contact us today for a consultation and see if it’s the right fit for your organization.

How to Select, Print, and Encode RFID Tags (Webinar)

About This Webinar:

How to Select, Print, and Encode RFID Tags

Wednesday, August 3rd, 2:00 PM – 2:30 PM ET

Presented By:

Chris Brown – RFID Subject Matter Expert at TSC Printronix Auto ID

Carlo Emanuele – Vice President and General Manager, Consumables at Barcodes Group

About the RFID Tag Webinar

IDTechEx forecast that 41.2 billion RAIN RFID tags will be sold in 2024, up from 15 billion just three years ago.

To enable you to track your assets with unprecedented accuracy, using the right tag will determine the success of an RFID implementation from the very beginning.

But how do you determine the encoding scheme to use at your organization, and the most appropriate tag or label to support this?

During this webinar, the following questions are answered:

- Why do you need to be concerned about encoding “good data†to RFID tags?

- How do you select an RFID tag that finds the optimal balance between size and read range?

- What role can a partner play in assisting with pre-printed/pre-encoded labels or providing solutions for your on-demand printing?

Watch the RFID Label Webinar

For an assessment of how RFID can improve your inventory accuracy and shipment verification process, please reach out to us at [email protected] or visit www.barcodesinc.com/solutions/learn-more-about-rfid/.

How RFID Cycle Counting Can Increase Speed at Lower Costs (Webinar)

About This Webinar:

RFID Cycle Counting: Increase Inventory Collection Speed at Lower Costs

Thursday, June 30th, 2:00 PM – 2:30 PM ET

Presented By:

Matt Smith – SLS

Christopher Vassilos – Barcodes

Why RFID for Cycle Counting is Transformative

Most businesses today conduct inventory counts as part of their operations. Traditional means of collecting this data include tallying products on a count sheet or scanning barcodes off product labeling, both of which are time consuming and prone to error.

Using RFID technology for cycle counting reduces labor cost and automates the workflow. The result is greater accuracy, improved asset utilization, as well as reducing lost or out of inventory situations.

During this webinar, you will be shown the following:

- A demonstration of cycle counting using RFID technology in action

- An overview of the components of the SLS Mobile Solution

- Various scenarios of deployment, including the use of robotics

Watch the RFID Cycle Counting Webinar Recording

We hope to see you there! For an assessment of your company’s ROI potential with RFID, please reach out to us at [email protected] or visit Barcodes and SLS RFID Solutions.