Fast and Reliable Industrial Label Printing with the cab Squix

What Are The Benefits of the cab Squix Industrial Label Printer?

The cab Squix industrial label printer has a compact design and is used in a wide range of applications, with a focus on easy, intuitive and high reliability. It is manufactured from high-quality materials and can come with many peripherals and software to enable customer-specific solutions. Check out what makes the cab Squix the industrial label printer the right one to deploy in your environment:

- Reliable and fast printing – from 5.9†to 11.8†per second

- Accurate print images – 203, 300 and 600 dpi options

- Easy to operate – can print various widths with no adjustment

- Compact design – 7.8†x 11.3†x 18.1†(W x H x D)

- Maximum quality standards – prints the smallest labels in the market

- Flexible – over 30 different accessories that can be added (cutters, rewinders, applicators, scanners, memory, etc.)

- Connectivity – standard with USB, Serial, Ethernet, Wi-Fi plus offers 3 extra USB ports for peripherals

- Data Protection – cabProtect is a standard feature that protects data being sent to printer

What Does the cab Squix Look Like?

- Hinged Cover: Material stock can be checked, and entire printing processes followed through a large panoramic window.

- Plungers: One is fixed on the inside. To get a good print image, the second one is moved to the outside margin of a label.

- Rugged Metal Chassis: Made of cast aluminum to assemble all the units.

- Coated Print Rollers: Synthetic rubber is a standard to get highly accurate print images. Silicone coating is an option for extra-long service life.

- Peel-off Function: To separate labels from the liner. A powered guide roller and a pinch roller enable highly accurate imprint and peel-off.

- Peripheral Port: To plug additional modules easily and quickly. They are screw fixed.

- Ribbon Holder: Ribbons are quick and easy to replace using three-part tightening axles.

- Roll Holder: Constant tension by means of the margin stop (spring-mounted, screw-capped) while material is fed.

- Internal Rewinder: To wind labels or liners with or without a cardboard core on peel-off devices. Materials are easy to handle using a three-part tightening axle.

- Rocker: Suspension and Teflon-made guide rollers reduce traction and improve the accuracy of print images.

- Material Guide: Assembled to the rocker. By a user turning the rotary knob, the stop moves to the margin of a label.

- Print Image Accuracy: The smaller a label, the higher are the demands. Using slip correction, print offset can be reduced by ±0.2 mm.

Where Does the cab Squix Industrial Label Printer Fit?

The cab Squix industrial label printer is used across a wide range of industrial applications. Some common uses cases include PCB Labeling, Type Plate Labeling, Cardboard Labeling and Pallet Labeling. While the cab Squix is best-in-class for printing small labels, it is also a go-to printer for printing of Odette, UCC and GS1 labels in the Transportation and Logistics` industry.

Contact us today for a free assessment and see if the cab Squix label printer is right for your operation.

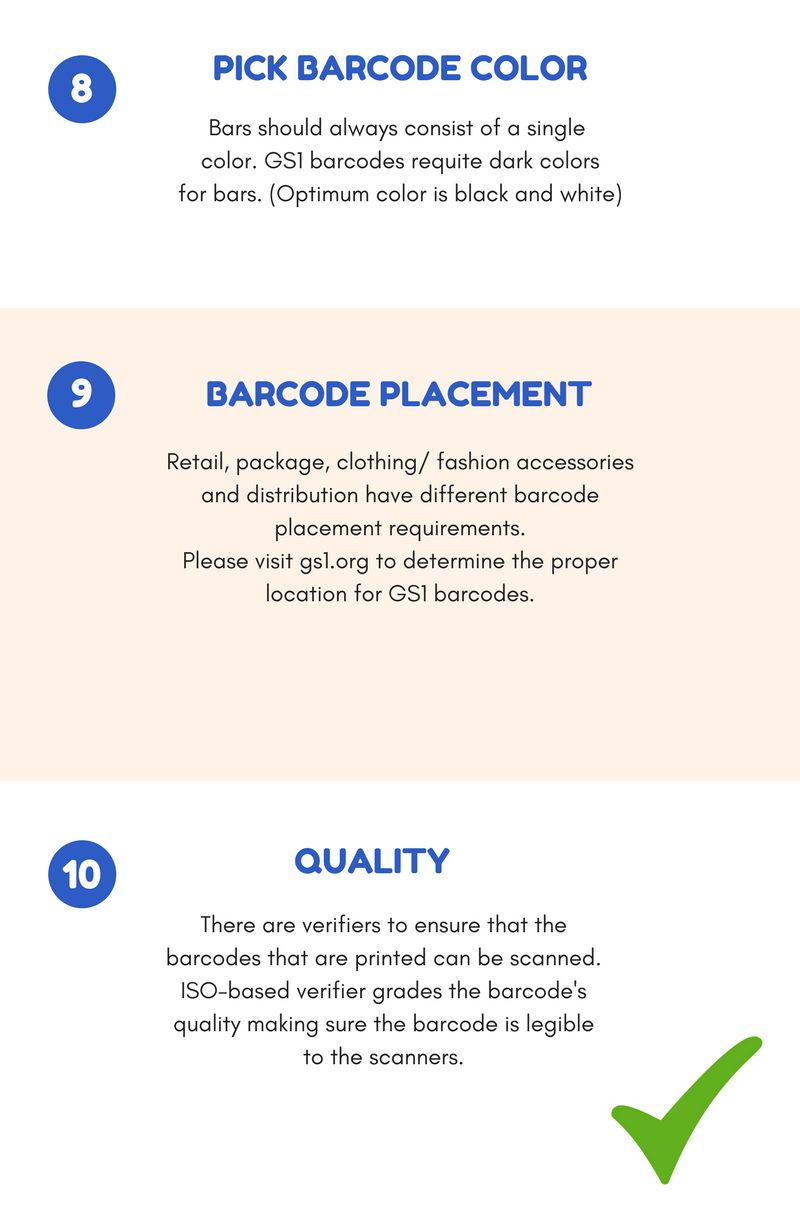

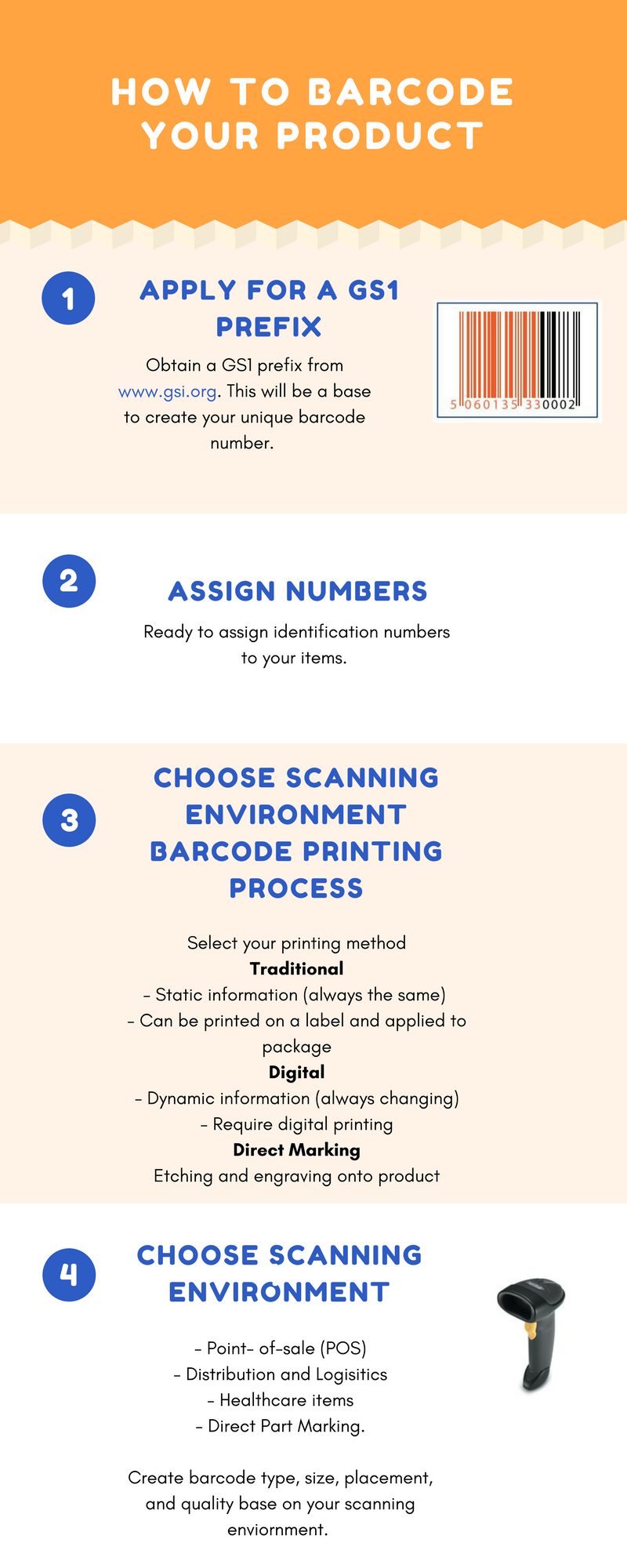

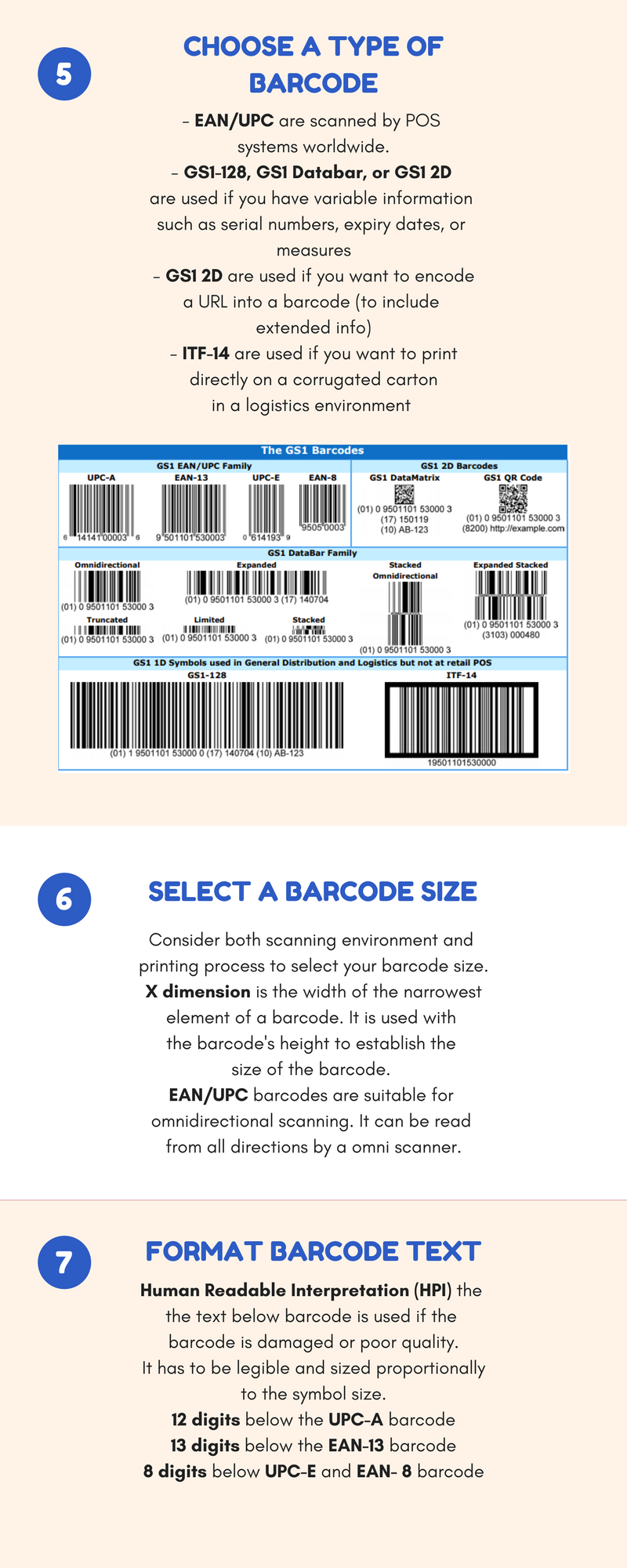

Tech Tip Tuesday: How To Barcode Your Product

To barcode your own product, there’s a few steps you should follow. First, determine if you need an unique barcode number for your product. If you do, follow the steps below to learn what you need in order to get your product out the door. Once you have the barcode, contact one of our dedicated account managers to find the printer and supplies that’s suitable to your need and get started on printing your own.

Barcodes, Inc. Delivers and Astute Solution

Challenge

Challenge

Astute Medical manufactures biomarkers that are used to identify high-risk, acute medical conditions in critically ill patients. The Federal Drug Administration (FDA) issued a mandate that medical devices must carry a Unique Device Identifier (UDI), which requires a greater volume of information than had been previously required.

Astute Medical sought a compliance labeling solution that would meet UDI requirements in accordance with GS1 Standards. The manufacturer also wanted to receive accurate and repeatable verification results and a solution that included a Validation Protocol to document compliance with these requirements. We needed to not only comply with federal regulations, but also ensure that we were sending out our medical devices with a high-quality barcode, “to avoid returns,” explained Susan Shelton, Materials Management and Procurement Manager of Astute Medical.

Analysis

Astute Medical designs, engineers, and manufactures novel biomarkers that enable clinicians to identify acute conditions in their critically ill patients before the symptoms become evident. Products like the NephroCheck Test and Astute140 Meter fall under the guidelines of the FDA’s Unique Device Identification rule. This system was established to identify medical devices throughout their distribution and use, providing critical traceability that benefits the patient, caregiver, manufacturer, and distributor.

Three Key Concerns for Barcode Verification

When you hear the term verification in regards to printing barcodes we are referring to much more than just making a readable barcode. Verification is a much more specific requirement for the quality of a 1D barcode or 2D symbol according to an agreed-upon quality standard. Not meeting these standards with your customers, be it Walmart or the DoD, will end up costing you in fines and time lost.

When you hear the term verification in regards to printing barcodes we are referring to much more than just making a readable barcode. Verification is a much more specific requirement for the quality of a 1D barcode or 2D symbol according to an agreed-upon quality standard. Not meeting these standards with your customers, be it Walmart or the DoD, will end up costing you in fines and time lost.

Lucky for all of us we have manufactures like Microscan who make verification easy so you can catch the barcodes that don’t meet the mark before they ever leave your facility. There are essentially 3 main things that can go wrong when printing a barcode that will lead to failing verification.

40 Year Anniversary of the First Barcode Scan

Today marks the 40 year anniversary of the first scan of a GS1 barcode in a retail environment – which all started with a pack of Wrigley Juicy Fruit gum at a Marsh Supermarket in Troy, Ohio on June 26, 1974!

Today marks the 40 year anniversary of the first scan of a GS1 barcode in a retail environment – which all started with a pack of Wrigley Juicy Fruit gum at a Marsh Supermarket in Troy, Ohio on June 26, 1974!

No one could have ever expected how a simple technology like the barcode would go on to shape and mold the retail landscape. The familiar beep of the scanner is now heard around the world up to six billion times a day!

TSC Label Printers Pass GS1 Barcode Testing and Certification

In recent years, the growing popularity of smart phones has triggered the increased use of two-dimensional barcodes, which offer large data-storage capacity and are secure and easily readable. This has resulted in the need for standardized tests, including GS1 certification testing, to ensure the quality and readability of two-dimensional barcodes.

In recent years, the growing popularity of smart phones has triggered the increased use of two-dimensional barcodes, which offer large data-storage capacity and are secure and easily readable. This has resulted in the need for standardized tests, including GS1 certification testing, to ensure the quality and readability of two-dimensional barcodes.

Eleven TSC barcode label printers have recently passed rigorous GS1 two-dimensional barcode tests and have been found to be in compliance with international standards. The 11 models, supporting Data Matrix, QR code and GS1 Databar barcode types, were tested with 88 different labels and passed 18 ISO IEC 15415 two-dimensional barcode quality tests. The validation testing, which included light source, print quality and other assessments, was done using advanced measuring instruments and stringent control standards.

The UPC Barcode – The Most Scanned Barcode in the World

In has been 40 years now since a group of grocery store executives collectively decided to help unify product identification with the use of a barcode. No one would have know at that time that a simple set of black and white lines would become one of the most important technologies for trade in the 20th century.

In has been 40 years now since a group of grocery store executives collectively decided to help unify product identification with the use of a barcode. No one would have know at that time that a simple set of black and white lines would become one of the most important technologies for trade in the 20th century.

The Universal Product Code (UPC) was the first movement to a standardized tool that every manufacturer and retailer could use to easily track products, maintain inventory better, and help speed up check-out lanes at the point of sale. The humble UPC hasn’t changed much since its creation in April 1973 but continues to provide an easy and efficient means to manage any product throughout its life cycle.

To better illustrate the UPC bar code’s extensive use and importance, Brussels-based nonprofit GS1, which maintains international UPC standards, has posted an online ticker to count the number of bar codes scanned around the world each day. According to GS1, the average number of daily scans clocks in at more than 5 billion! To think all this started with the first scan of a 10-pack of Juicy Fruit gum at a Marsh Supermarket in Troy, OH in 1974.

Microscan Now Certified as a US GS1 Solution Partner

Microscan has announced their recent certification as a U.S. GS1 Solutions Provider. The designation reinforces Microscan’s commitment to providing manufacturers with expert solutions and services that address barcode verification applications and compliance with GS1 standards.

GS1 is an international association dedicated to the development and promotion of global standards and solutions in a broad range of industries, including barcode and identification tools. With 30 years of Auto ID experience, Microscan can offer guidance and support to companies implementing GS1 Standards, and employs certified GS1 Barcode Professionals on its staff with the knowledge and experience to successfully implement barcode verification solutions in industries ranging from electronics assembly to pharmaceuticals to food and beverage packaging.

GS1 US Celebrates 40 Years of the Barcode

This year marks the 40th anniversary that organizations united to adopt a universal way to conduct business using GS1 Standards. Beginning with a UPC (Universal Product Code) barcode, the GS1 System of Standards has set the foundation for a technological revolution that has changed the way companies, from manufacturers to retailers, conduct business around the world. Now, more than five billion GS1 barcodes are scanned every day.

This year marks the 40th anniversary that organizations united to adopt a universal way to conduct business using GS1 Standards. Beginning with a UPC (Universal Product Code) barcode, the GS1 System of Standards has set the foundation for a technological revolution that has changed the way companies, from manufacturers to retailers, conduct business around the world. Now, more than five billion GS1 barcodes are scanned every day.

In the 40 years since their adoption, GS1 Standards have grown into a global system, used by more than two million companies doing business in 150 countries across 25 industries, including apparel and general merchandise, fresh foods, consumer packaged goods, grocery, foodservice, healthcare, and defense

Introduced to speed the supermarket checkout process, the grocery retail industry was the first champion of standards in 1973. Today, supply chains representing nearly every sector in the world rely on GS1 Standards for identifying, capturing, and sharing information about goods, services, locations, and more in real-time. Barcodes and Electronic Product Code (EPC) enabled radio frequency identification (RFID) have evolved to capture a broad range of information to drive supply chain visibility.