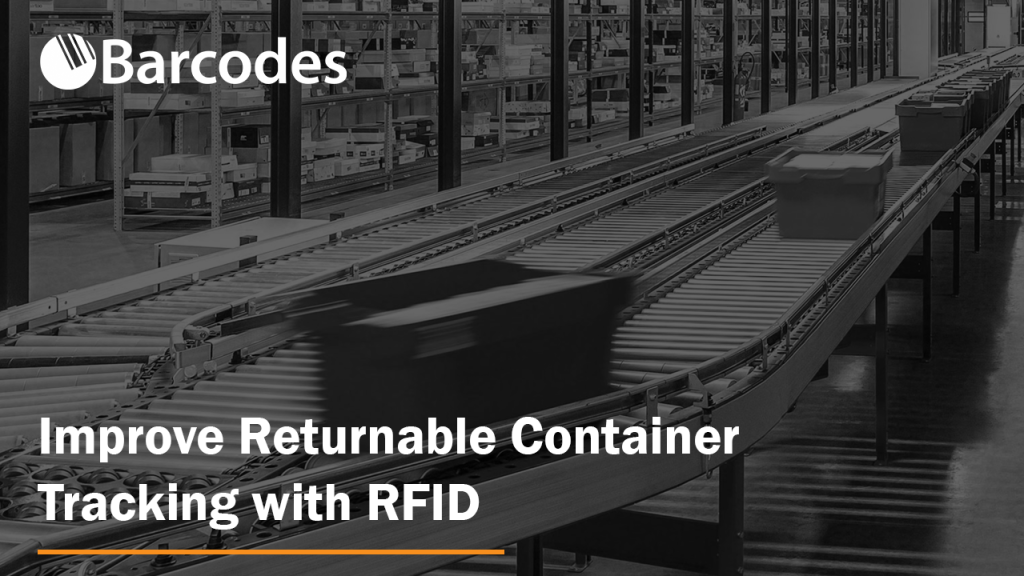

RFID Webinar: Improve Returnable Container Tracking with RFID

Webinar

Improve Returnable Container Tracking with RFID

Thursday April 20th 1:00-1:45pm Central

PRESENTED BY:

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Michael Daily – Senior Solutions Engineer, Impinj

RFID-Based Container Tracking

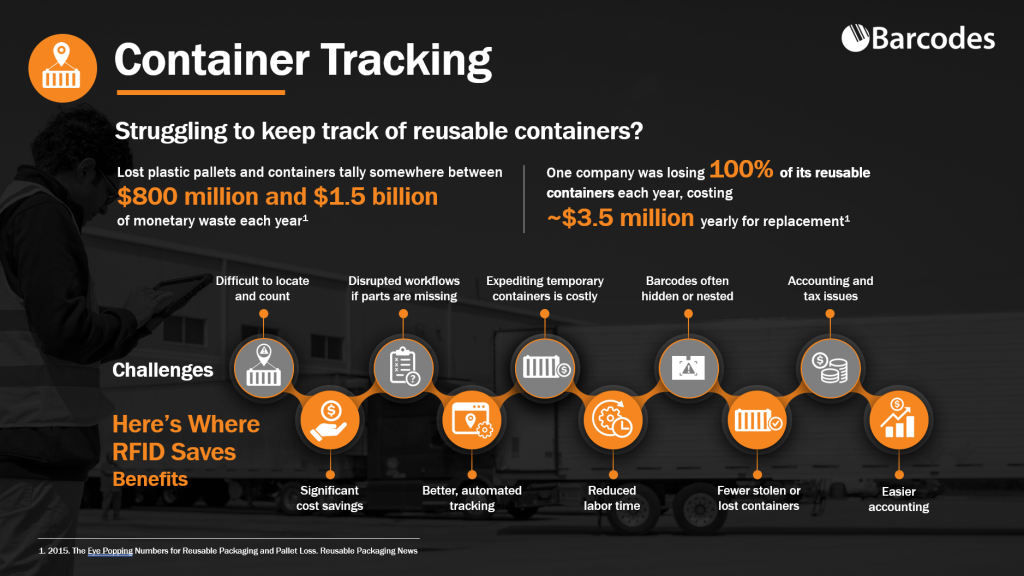

Upon delivery, it’s common for reusable containers to not be returned to the sender, with annual shrinkage rates often exceeding 10%. Keeping track of your Returnable Transport Items (RTIs) can be challenging, especially when logging their location depends on manual processes like scanning.

In this webinar, discover the benefits of RFID-based container tracking:

- Reduce the number of misplaced pallets, kegs, and boxes. Less new delivery assets need to be purchased, and shipments are not interrupted due to lack of totes.

- Track each asset as it leaves and returns to the warehouse, allowing you to determine its exact location immediately and whether they have yet to return.

- Calculate the flow of returnable assets to fully understand your shipping capacity for the present and future.

- Improve utilization of workers since it takes way less time to scan RFID tags than barcodes, due to its fully automatable reading without line-of-sight requirements.

Watch the Full RFID Webinar Recording

Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.

3 Ways High-Performing Mobility Optimizes the Discount Store Experience

Customer expectations have shifted drastically, reshaping today’s storefronts to deliver faster service, consistent product availability, and bolstered customer satisfaction. As a result, retail-ready technologies must now work harder and faster to keep storefronts ahead of demands. Complex workflows can no longer be tolerated, which is why high-demand storefronts such as discount stores are equipping their teams with enterprise-ready mobile devices. As part of an end-to-end mobility solution, next-generation mobility can increase worker performance and meet high demand without overwhelming store associates.

Turning mobility into profitability

Designed to sustain productivity in fast-paced environments, newer enterprise-grade devices such as Zebra’s line of mobile computers and printers streamline workflows to enable…

- Quicker shelf replenishment – Out-of-stocks are one of the top drivers of lost sales. To prevent empty shelves from driving customers away, mobile devices can function as both scanners, computers, and communicators, allowing employees to quickly locate dwindling stock in real-time and replace products.

- Enhanced cybersecurity – If a device is connected to a network, it is vulnerable to cyberattacks. Consequently, modernized mobile devices running on Android are equipped with higher security measures to ward off unauthorized users from accessing sensitive data such as payment information.

- Faster frictionless checkout – The checkout lane is one of the most critical foundations of the customer experience. Intelligent scan engines can help reduce wait times by ensuring more successful first-time scans in less time both at the checkout lane and for curbside pickup.

Download our brochure to discover how expert insight can empower your discount store to surpass expectations. For more information on deploying versatile technologies into your storefront, contact Barcodes, Inc. here.

Introducing Honeywell’s Granit XP Ultra-Rugged Scanners

Barcode scanning has been widely deployed in manufacturing environments, as well as distribution and fulfillment centers. However, in fast-paced workflows, handheld devices can take a beating, increasing the maintenance costs of devices and decreasing reliability. Damage to barcodes (or poor quality of internally printed labels) can reduce scanning speed and efficiency, or require users to manually enter data, a process that is much slower and more vulnerable to error.

The latest models in the Honeywell Granit XP line were designed to address these challenges, offering best-in class durability, premium scanning performance, and purpose-built scanning range to drive efficiency and reliability in these mission-critical applications.

The Granit XP series of wired and wireless scanners are available in Standard Range (SR) and Extended Range (XR) versions. The SR will eventually replace the Granit 1910i and 1911i, and the XR establishes a new category of scanner that can scan equally as well up close as it can far away. Customers no longer have to compromise up close barcode scanning speeds in order to scan barcodes from a distance.

The Granit XP is compatible with existing Granit accessories, simplifying implementation and mixed deployments.

What Applications are Best for Each Scanner?

- Granit 1990iSR (wired) and 1991iSR (wireless): Scanning barcodes from contact to arm’s length.

- Granit 1990iXR (wired) and 1991iXR (wireless): Scanning barcodes from contact to 33 feet.

- Granit 1980i (wired) and 1981i (wireless): Scanning barcodes from contact to 52 feet and beyond.

The Granit XP series offers best-in-class durability, premium scanning speed (even on low quality barcodes), and a portfolio of products that provide compelling solutions for the most common applications in warehouse, DC, and manufacturing environments.

Contact us today if you have any questions or would like to receive a custom quote.

Transforming Retail with RFID

With the highly- competitive retail landscape, today’s retailers must tackle many challenges in the era of industry transformation. Customer are expecting more when they enter a retail store, so how do you stay ahead? Register for our webinar to learn more about how can you transform retail with RFID.

With the growth of e-commerce, it has become evident that inventory visibility and accuracy is more important than ever.  Consumers will want the most easiest path to purchase what they want and receive it quickly. An inventory system needs to provide retailers most efficient way to fulfill consumers orders. Join Barcodes and Zebra to learn about the current trends and the way that RFID is making a difference today!

Transforming Retail with RFID

Thursday, January 24 from 11-11:30 AM CST

Presented by:

Maximize Productivity at Your Warehouse with the Janam XG200

Introducing Janam’s XG200 rugged mobile computer, where it is designed to handle all the unique requirements of warehouse, distribution centers, loading docks, delivery, and more! With its industry leading design, superior scanning, processing speed, and Android 7 OS its built with all the winning features at the right price.

With Windows ending their mobile handheld support in 2020, it is a good opportunity to make a transition to the Janam XG200 to increase mobile worker productivity. The mobile device sits at just 20.7 ounces with a pistol grip designed for effortless operations. Extreme ruggedness to handle the harsh work environment, fully dustproof with an IP65 sealing, and can operate in a wide range of temperatures, including freezers.

- Superior 1D and 2D barcode scanning

- Android 7 Operating system with Google Mobile Services (GMS)

- 4.3 inch Gorilla glass touch screen

- Sleek and lightweight design for ease of operation

- IP65 standard to protect against water and dust

- Wi-Fi and Bluetooth

- 6300 mAh Rechargeable and hot swappable battery

Contact our dedicated account managers if you need a warehouse inventory or asset solution. Click on the video above to learn how the Janam XG200 can increase productivity in your warehouse.

Adapt For The Future with Barcodes and Zebra

Traceability in any industry is important, whether you are scanning products in retail, warehouse, medicine, or shipping labels. Data need to be capture to hold information that needs to be fulfilled. Update the tools you need to eliminate extra steps, meet the growing demand, and exceed your productivity goals.

Advance your daily operations and ensure that you can scan it right on the first time for faster data capturing, decrease processing time, and please all your smart shoppers. Read the infographic to see how Barcodes can provide you with the solution that you need with Zebra products. Contact us for a free assessment and let us know if you have any questions or concerns and we can show you the way to prepare for the future.

Bringing Value to the In-Store Experience

Higher Expectation: As consumers have grown accustomed to more shopping choices in our connected world, they have raised the demands they make of retailers. Leading to now the retailers must offer a more compelling value to entice customers to make a trip to a brick- and – mortar store.

Solution: Read the e-book below to learn about the solution that the retailers came up with to respond to shopper’s demands more quickly and efficiently to improve their shopping experience.

Click the E-book below to read more.

Your 10 Considerations for The Right Mobile Device!

With so many mobile devices choices out there for business users. How do you know which one

will meet your needs and your users?

Read the infographic below and see what’s the best way to choose the one you need in your

workforce and how Barcodes, Inc. and Zebra can help you find the solution that works best with your

company.

Janam’s 3Ps with the XT100: Power. Performance. Price Advantage.

Janam’s new XT100 rugged touch computer, you can easily equipped your mobile worker with a line of business applications in the palm of their hand.

The XT100 will give you the maximum return on investment, it’s ease of accessibility gives your worker more efficiency and productivity. Additionally, with it’s ruggedness, it is designed to meet every industry needs. The XT100 provides the latest technological advances to organizations of any size at an extremely attractive price point.

Featuring a sleek smartphone design, it’s also:

- Built with an Android 6.0.1 operating system

- Well lit 4.3-inch touchscreen made with Gorilla Glass 3

- Wide-viewing angles

- Superior 2D barcode scanning

- Integrated with RFID and NFC capability

- Lightning fast voice and data

- Certified by Google Mobile Services

- With Removable and rechargeable battery

If you have any questions or would like a quote, please contact one of our dedicated account manager.