Brother RuggedJet 4250WBL Mobile Barcode Printer

Print Labels, Tags, Invoices, Quotes, Receipts, and More on the Spot

The Brother RuggedJet 4250WBL mobile label and receipt printer raises industry standards with a smart new way to manage and deploy printers.

Like other RuggedJet printers from Brother, the 4250WBL is well designed to meet the needs of a busy mobile workforce, in the field or inside the four walls.

To support efficiency and changing connection requirements in your facility, the RJ-4250WBL offers a wide variety of connectivity options (including twin Wi-Fi® and Bluetooth® radios).

With AirPrint®, you can immediately get started printing straight from your screen without having to write or use an app.

All the capabilities you need to print 2-inch to 4-inch labels for shipping, pallets, picking/packing, and more across your organization are available on this very tough, high-performing, and rechargeable printer.

Benefits of the Brother RuggedJet 4250WBL Mobile Barcode Printer

- Fast, efficient print speeds up to 5 inches per second

- Reinforced parts and sturdy construction

- IP54 certification for dust/moisture and 6.88 foot drop protection

- Easy to connect and pair with any device

- Smart, reliable lithium ion battery

- Compatible with Windows, Android, Apple iOS, and AirPrint

- Accessories for even greater mobility, such as mounts, cases, straps, and adapters

For a closer look, download the RJ4200 series spec sheet. When you are ready for a deeper conversation about how to deploy 4250 printers to your workforce, reach out to us.

Honeywell PM45 Industrial Printers: Maximum Productivity in Distribution Environments

There are more and more problems with production flexibility, inventory turnover, and cost control for businesses today.

The Honeywell PM45 industrial printer is made to give businesses the freedom and accuracy they need to print high quality barcode labels, RFID tags, and more at scale.

The track-and-trace feature of the PM45 printer is meant to improve print efficiency and supply chain transparency in many different industries, such as the food and beverage, pharmaceutical, manufacturing, warehouse, and distribution center management industries.

The reliable PM45 printer is built on the Honeywell print platform and can print at speeds of up to 14 ips. With a print registration range of up to +/-0.5 mm, the PM45 printer can print high-quality barcodes, text, and images, even on small labels for electronic parts and medical devices.

As an industrial printer with a lot of connections, the PM45 has improved WWAN connectivity so that deployment isn’t too limited by the site’s network topology. Because the PM45 printer is so flexible, the user can add RFID, parallel, industrial, and applicator interfaces to meet unforeseeable business needs in the future.

The PM45 printer supports variable network protocols and multiple print languages to make it easy to integrate into your system, whether it is in the cloud or on a local server. This will help you move toward intelligent manufacturing and supply chain management.

With Honeywell’s Smart Parse software built in, the PM45 lets you quickly change the position of objects and barcodes, the size of objects and barcodes, or the font type on labels without having to make changes to the backend system or know how to code.

With Honeywell’s Operational Intelligence software, users can manage and keep an eye on the diagnostics and output performance of the PM45 printer from afar. The PM45 works with a wide range of media, including ink-in and ink-out ribbons with a 1-inch core size. This makes it easier to go longer without having to restock media.

Since Honeywell’s firmware platform supports multiple print languages, the PM45 printer is a great replacement for Honeywell or mixed printers that are already in use. A durable, all-metal print mechanism, an easy-to-replace printhead, and a platen roller that doesn’t need any tools to be changed all help to reduce downtime and maintenance needs.

Watch the Honeywell PM45 Video

The Honeywell PM45 is a productivity powerhouse. Additional features include:

- Accurate & reliable high speed printing (direct and thermal transfer)

- Broad connectivity options

- Device management and track & trace functionality

- Compatible Software, including Nicelabel, BarTender, Operational Intelligence, Teklynx Labelview

- Compatible Drivers, such as CUPS Driver for Linux, InterDriver for Windows, and Certified Device Types for SAP

For a full list of detailed specifications, download the PM45 spec sheet.

Zebra ZQ600 Plus Mobile Printers Set a New Standard for Enterprise Mobility

The ZQ600 Plus mobile printers produce high-quality label and receipts anywhere, whether in the order picking fleet in the warehouse, or on the road in a delivery driver’s arsenal.

ZQ600 and ZQ610 Plus printers improve Zebra’s popular QLn platform by adding new technology and design that make them easier to use, more productive, and easier to manage.

The ZQ series printers never fall asleep on the job thanks to a feature called “instant wake-up.” Also, your mobile workforce gets the fastest and most reliable wireless connections.

Your IT department will find it easier to integrate, set up, and secure the printers thanks to Zebra’s Link-OS operating system and powerful Print DNA suite of applications, utilities, and developer tools.

It’s safe to say that the ZQ600 Series printer is the gold standard for printing labels and receipts from a mobile device.

What are the Main Benefits of the Zebra ZQ600 Plus Printer?

The Zebra ZQ600 Plus is a mobile printer designed for use in a variety of operational settings. Some potential benefits for operational leaders include:

- Rugged design: The ZQ600 Plus is built to withstand rough handling and harsh environments, making it ideal for use in field operations or other demanding settings

- High-quality printing: Each EQ600/610 Plus produces high-quality, crisp and clear prints, which can be important for producing accurate and professional-looking documents in operational settings

- Wireless connectivity: Bluetooth and WiFi make it easy to print from other devices in the field or on the go

- Customization options: The ZQ600 Plus can be customized with a range of accessories and options, such as label peelers and cutter options, to suit the specific needs of different operational settings

- Easy to use: ZQ600 printers include a simple and intuitive interface and easy-to-load media, which allows leaders to quickly and easily train new users on the printer, reducing downtime and increasing productivity

For a detailed list of features and specifications, download the ZQ610 printer spec sheet.

See the ZQ600 Plus Printer in Action

This coming year, rely on Zebra mobile printers to get the job done quickly and efficiently, anywhere your workforce goes.

Contact us to discuss your mobile label, tag, and receipt printing needs.

Print Receipts Anywhere Easily with the ZQ300 Plus

The ZQ300 Plus mobile printers produce high-quality label and receipts anywhere, with a user-friendly design, improved print speeds, and easier device management for operational leaders.

Zebra’s ZQ300 Plus printers give your retail team members freedom of movement anywhere on the store floor.

Mobile receipt printing enables customer sales and quicker stockroom deliveries for drivers.

With on-the-spot label printing, store employees can do markups, markdowns, and shelf label checks more quickly and accurately.

The Zebra ZQ300 Plus Series has the same features and specs as the ZQ300 Series, but it uses updated circuitry to make sure that the products will still be available in the long run.

What We Love About the Zebra ZQ300 Plus

With the ZQ300 Plus printer, you can improve the retail customer and employee experience in a variety of ways:

- Its simplicity makes it easier to train employees, with clear instructions, a beautiful onscreen display, and low learning curve

- The ZQ300 Plus printer prints personalized receipts, labels, and other materials for customers. Customers will have a more personalized and memorable experience as a result

- The ZQ300 Plus reduces wait times and increase overall store efficiency, improving the customer experience by reducing frustration and streamlining the checkout process

- Easy to maintain and clean, ensuring optimal performance and high-quality prints every time

- The ZQ300 Plus printer can be used to provide further value to customers by printing coupons or loyalty cards

For a detailed list of features and specifications, download the ZQ300 printer spec sheet.

Watch the ZQ300 Plus Printer Video

Zebra mobile printers get the job done quickly and efficiently, anywhere your workforce and customers are.

Contact us to discuss your mobile label, tag, and receipt printing needs.

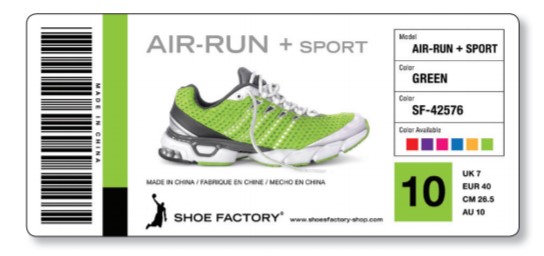

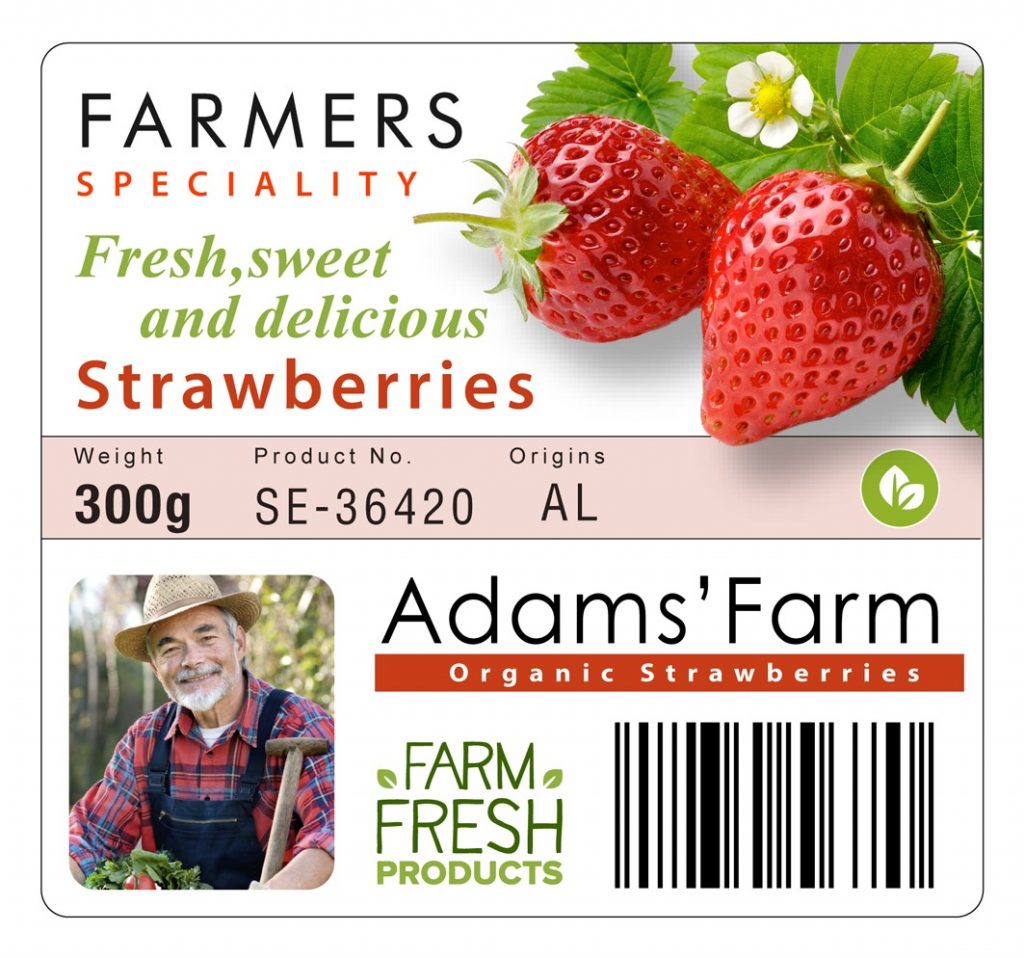

Epson Colorworks C7500 Label Printer Can Help Brand Your Business

On a shelf, where thousands of products compete to be noticed, companies have to use clever packaging to draw attention.

In fact, 64% of consumers will buy products based on their packaging.

Color labels enable fast, accurate product identification and consistent packaging. This ultimately improves brand recognition, shelf appeal, and a deeper consumer connection.

Print Color Labels with the Epson C7500 Label Printer

By printing labels in-house with the Epson Colorworks C7500 label printer, you have the ability to create labels for your products in the most affordable and efficient way.

The C7500 color printer is designed to increase printing efficiency of color labels. Engineered for industrial label production, with a standard autocutter and optional rewinder, it allows users to fulfill high label requirements and variable printing demands.

Employees will be able to print high- quality labels on-demand and save money with the cost associated with pre-printed labels. Epson’s patented PrecisionCore technology on its printhead is a critical feature that ensure consistent high quality prints and prevents any dead pixels on the labels.

Its Nozzle Verification Technology that detects and resolves block nozzles to help prevent misprints. Futhermore, the Epson C7500 color printer uses pigment ink to create fast drying, long-lasting labels that resist smudging, water, and fading.

Perfect for applications when you need to produce a range of labels for food, beverage, packaging, energy, and GHS labels, and more. With print speed up to 10.4 inches per second, you can print labels in full color with no compromise on print quality.

Epson C7500 Printer Features:

- High-speed, on-demand color printing

- Prints on wide range of materials up to 4 inches in width

- Print full, die-cut, plain, matte, synthetic, and gloss labels

- USB and Ethernet interface

- Maximum resolution 600 x 1200 dpi

- Astounding image quality powered by PrecisionCore inkjet technology

- Use with Epson’s durable labels available to BS5609 standard for GHS chemical labeling

See the Epson C7500 Printer in Action

Customize your products with text, barcodes, and colorful graphics to stand out from the rest.

Contact us if you have any questions or would like to learn more about how the Epson Colorworks C7500 color printer can help you brand your business.

Where to Place an RFID Inlay

Printing and encoding RFID “smart labels†with an RFID-enabled printer has traditionally been difficult; a classic case of “the Devil is in the details.â€â€¯ One difficulty users have wrestled with has been “inlay placement.â€â€¯ Inlay placement refers to the location of the RFID inlay under the label’s face stock.  Although inlays are generally oriented horizontally under the face stock, the inlays can be located towards the bottom of the label, towards the top, or anywhere in between.  In the picture to the right, for example, the inlay is relatively close to the bottom of the label, the “leading edge†as it is often called, because this edge comes out of the printer first.

Almost every printer brand – and even model – has traditionally had detailed, complex specifications regarding inlay placement, with different specifications for each and every inlay on the market.  The location of the inlay has to be a particular distance from the leading edge of the label in order to maximize the printer’s throughput (speed).  Just a millimeter or two either way, and the performance of the printer can suffer dramatically.  What a mess.  Given that printing and encoding RFID labels is already slower than printing traditional barcode labels, any further loss in performance has often been catastrophic for the end-user.  Waiting for your RFID labels to print and encode can hold up an entire production line.  This all meant that for your printer brand and model, you needed to make sure to order labels with an optimal inlay placement.

Precise inlay placement also causes some additional problems:

- It makes selecting labels more difficult. Users need to order their labels very carefully to ensure correct inlay placement.  Does your purchasing department understand inlay placement?

- It can cause delays in sourcing labels.  Often, a convertor (label manufacturer) will have exactly the label size you need – but with incorrect inlay placement for your printer.  To get labels with optimal inlay placement, the convertor needs to configure their entire production line and run a new batch of labels for you.  This can take several days to several weeks.

- Finally, requiring a specific inlay placement can mean that users may pay more for their labels.  A quick Google search of classic paper thermal transfer 4×6 RFID shipping labels will show some surprising results.  The very same labels from the very same vendor can have dramatically different prices depending solely on inlay placement.  It all boils down to supply and demand, but if you are on the wrong side of the equation, you may have to pay significantly more for your labels.

With Printronix Auto ID’s current line-up of RFID printers, these headaches associated with inlay placement are now a thing of the past.  Printronix RFID printers have a unique firmware (the software brains in the printer), which does what they call “Encode During Print.â€â€¯ In clearer language, this means that the printer will first print some of the label, then switch over to encoding, then switch back to printing and finish up the label.  The printer will automatically either print or encode at any given moment depending on where the label is relative to the printer’s printhead and RFID encoder.  The traditional approaches for RFID printers were to either first print the entire label, then encode the RFID portion (“Print then Encodeâ€) – or to first encode the RFID, then print the label (“Encode then Printâ€).  But with these traditional approaches, if the inlay is not optimally placed, then the printer needs to back- or forward-feed the label to align it for an operation (printing or encoding) at any given moment.  With Printronix’s Encode During Print functionality, back- and forward-feed are eliminated (other than to overstrike bad labels, which is another blog topic for another day), regardless of inlay placement.

So far, we have been talking about labels like 4×6 shipping labels that allow different inlay placements.  But what about all of the RFID labels, “tags,†on the market that have predetermined inlay placement?  For example, on-metal tags, plant stakes, small pharmaceutical labels for cold-chain applications, “RTI†tags (Returnable Transport Items), etc., etc.  There are many such tags on the market, and more are being developed and released all the time.  These tags generally have a fixed inlay placement based on their physical design and on simple commercial considerations – they are meant to be “Off-the-Shelf†(OTS) products.  This is another area Printronix’s Encode During Print functionality shines even more.  Because the Printronix printers do not care where the inlay is located, you can use any of these tags and still achieve maximum throughput.

And these unusual tags often pose physical feed challenges for RFID printers. For example, on-metal and RTI tags are often thicker than normal smart labels, and they can have abrupt edges between labels, large gaps, etc. Both Printronix’s T6000e and T4000 series printers were designed from the ground up to work with these more difficult constructions.  The printers are spec’ed for labels up to 1.2mm thick and are available in 4†and 6†print-widths, allowing you to print and encode a wide variety of tags from a single printer – all without sacrificing performance.

Finding the right RFID solution is always a challenge and having the right resources and help are critical. If RFID sounds like a suitable solution for your business or you have additional questions, feel free to contact us at Barcodes, Inc. We’re always happy to help you find the right solution for your needs.

Get Intelligence and Toughness with SATO’s CL4NX Plus Industrial Thermal Printer

Offering a vast array of standard features that are unequaled by its competition, SATO’s CL4NX Plus sets a new and groundbreaking industry standard for ease of use, intelligence, on-board emulations, connectivity, speed of processing data streams, user activity interface, and much more.

Built with integrity, designed with the user and productivity in mind, the CL4NX Plus supports up to 10-inch outside diameter of media and 1968-foot (600-meter) ribbon and incorporates Smart Printhead technology to keep track of usage specific to the mounted printhead. The platen roller with the Pure Line indicator provides a visual wear indicator so users can be proactive when it is necessary to change this vital component. The Micro Label Print Mode provides higher print accuracy for small pitch labels and can dispense labels as small as 10 mm.

Using SATO Application Enabled Printing (AEP), you can build custom standalone applications that can be run directly on the printer and connect peripheral devices directly to the printer for data input, such as a barcode scanner, keyboard, or weigh scale.

The CL4NX Plus Industrial Printer is fast, precise, and intelligent. It will exceed your expectations of the printing technology of today.

Shop the SATO CL4NX Plus Printer online or Contact your Barcodes, Inc. Account Manager for more information.

The Next Generation 4-inch Desktop Thermal Printer

Setting the bar for desktop barcode label printing, SATO’s CT4-LX is a 4-inch thermal printer offering features and functionality typically only found in industrial printer models but in a compact size. Designed with a full-color touchscreen display, the latest wireless connectivity options and patented label waste prevention feature, the CT4LX Label Printer is easy to operate and maintain with user-replaceable printheads and platen rollers to quickly keep your business up and running.

Key Features

– 4.3″ Full Color Touchscreen Display

– 203 or 305 dpi print resolution

– Thermal Transfer and Direct Thermal

– Label Waste Prevention – eliminates first label loss

– Apple iOS Connectivity

– Quick pairing with NFC-enabled devices

– Auto Switching competitive emulation languages (SBPL, SEPL, SZPL, SDPL, SIPL, or STCL)

– Auto RFID positioning with SATO RF Analyze (SRA)

– Remote management with SATO Online Services (SOS)

Connectivity Options: USB, Ethernet, Wi-Fi, Bluetooth, RS-232C

Optional Features: UHF RFID encoder (pre-installed), Auto-Cutter, Linerless Cutter, Dispenser, Real-Time Clock

Shop the Sato CT4-LX online or Contact your Barcodes, Inc. Account Manager for more information.

Print On-Demand Color Labels with The Epson ColorWorks C6000/C6500 Series

The first printer specifically designed as a color upgrade to black-and-white thermal transfer printers, the Epson ColorWorks Series of inkjet printers deliver on-demand, 4″ and 8″ color labels with fast-drying, durable color inks, while offering cost and inventory reduction compared to using pre-printed labels. Compatible with ZPL II, SAP, and more, and built to accommodate remote printer management, these versatile printers offer seamless integration with your existing workflow.

GHS‑Compliant Labels – Fast, efficient, durable GHS solution printing for your production floor

Fresh Food Labels – Fast, full‑color, high‑volume, heavy production labels for busy, fresh food production

Healthcare Label Printing – Fast, reliable printing for custom color‑enhanced labels for healthcare solutions

| ColorWorks Model | C6000A | | C6000P | Â | C6500A | Â | C6500P | |

| Key Feature | Auto cutter | Peel-and-present | Auto cutter | Peel-and-present | ||||

| Max. Print Width | 4.25-inch | 4.25-inch | 8.34-inch | 8.34-inch | ||||

| Roll Media Outer Diameter | 8-inch | 8-inch | 6-inch | 6-inch | ||||

| Roll Media Core Diameter | 3-inch | 3-inch | 3-inch | 3-inch | ||||

Contact us today for a free assessment and see if you have the right label printing solution in place. Ask us about TrueSupport and our other Design, Deploy and Support services.

Industrial Label Printing as it Should be with the Honeywell PX940 Industrial Label Printer

Error-prone, mis-printed and unreadable barcode labels continue to cost businesses tens of thousands of dollars annually due to chargebacks, fines and rejected shipments. For example, retailers like Walmart have detailed requirements for on barcode label design/placement. Non-compliance can cost the shipper $5,000 for the second infraction which can double with each infraction. In order to reduce fines and delayed shipments, you need a label printer that can change the landscape of the supply chain. Barcodes, Inc. and Honeywell can help you deliver an industrial barcode printing solution with integrated label verification. Watch how the Honeywell PX940 with Verifier is ideal for regulatory shipment printing:

Contact us today for a free assessment and see if you have the right industrial printing solution in place. Ask us about TrueSupport and our other Design, Deploy and Support services.