Barcodes at IFT19!

Visit Barcodes at IFT19 in booth 2841-K, June 2-5 at Morial Convention Center in New Orleans, LA!

We would like to invite you to attend the IFT19 Food Expo as our guest, free of charge. Click on the link below to register using our Exhibitor Code 2625. Select Attendee Registration & Housing and apply our code to the Exhibitor Code section at the bottom of the profile page. Passes are non-transferable and may not be used for exhibit company staff, family members or guests. IFT reserves the right to cancel registrations that are in violation of the usage policy.

ICYMI: How to Manage your Tools with Barcodes and RFID with Gigatrak

In case you miss our webinar today, click on the video and discover how Barcodes and Gigatrak’s Tool Tracking System can help you manage your assets, or tools through our self hosted or cloud solution.

In this webinar, you will learn about the benefits of Barcodes vs RFID tracking solutions, how it can help you maximize control and return of investments in your facility.

Key Components:

- Managing your tool and inventory can help you reduce operating costs and protect your investments.

- The benefits of using a tool tracking management system.

- How to choose which tag works best for your operations? Barcodes, RFID, or Both?

If you have any questions, please contact our marketing manager, Lorna Malja, at [email protected] or at 855-253-5508.

For Challenging Environments- Honeywell’s Granit 1980i & 1981i

For the toughest environment, comes the Honeywell’s Granit 1980i (wired) and the 1981i (wireless) industrial full range scanners. The area- imaging scanners are capable of scanning both 1D and 2D barcodes from near and as far as 50ft away. Simple to use, the Granit scanners maximize operator productivity in the most challenging environments and will be able to pair the scanners with fork trucks equipped with vehicle mounted mobile computers to scan barcodes at an extended range.

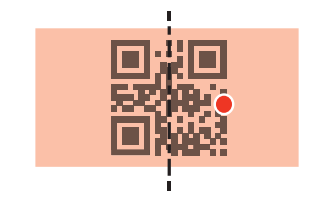

Near and Far Distance Scanning Techniques (1D & 2D):

Near and Far Distance Scanning Techniques (1D & 2D):

Near

Capable reading from 6 inches near barcodes. Hover over the barcode and center the red lightning box with laser aim to the right of the center of the barcode.

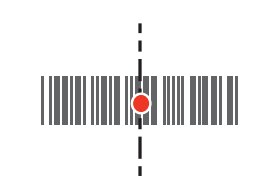

Far

Far

Distance scanning up to 50ft, with laser scanner aim at the center of the barcode. (with laminated barcodes might have to tilt the scanner at an readable angle)

Features:

- Full Range Area Imaging of 1D & 2D barcodes

- Super Rugged IP65 Rating

- Multiple scanning configurations

- Wire or Wireless enable mobility

- Ease of Use- Intuitive User Feedback

Equip your team with the toughest scanner to maximize your team’s productivity and lower the overall cost of ownership. The 1980i & 1981i Granit scanners are great for manufacturing, transportation and logistics, warehouse and distribution, and outdoor logistics.

Contact our dedicated account managers on any questions in regards how to improve your daily operations with the Granit scanners and we will be happy to help.

A Warehouse Robotics Company Implements iPad Mini & Powerful Barcode Scanning Solution

Executive Summary

Executive Summary

A warehouse robotics manufacturing company was in search of a user interface to complete and enhance their robots. A powerful barcode scanning solution with a strong and durable scan engine was required to improve processes. Additionally, it needed to be compatible with the iPad Mini due to their workers familiarity with the product and integration with their existing enterprise software.

Barcodes identified an optimal barcode scanning solution that not only streamlined processes but also increased the revenue stream for a robotics company’s clients.

The Business Challenge

The robots created by the robotics company are used at their customer’s facilities. A technologically advanced solution was required to allow warehouse associates the ability to interact directly with the robots for order picking, inventory control, and efficiency measures. They need a simple and lightweight solution to implement various warehouse management applications.

Solution

Barcodes recommended the Infinite Peripherals Infinea Tab™ M and case (CS-TAL) with 1D/2D barcode scanner, along with the Apple iPad Mini. This allowed mobile employees to convert the Apple iPad Mini into a powerful warehouse management and scanning solution to fulfill their operational needs. The Infinea Tab™ M has a 2D imager scan engine which reads the most widely used 1D and 2D barcodes that has made it the ideal solution for order picking and inventory control.

Benefits

Having implemented the solution, the warehouse robotics company has seen the benefits of using an iPad mini and powerful scanning solution in one. The intuitive user interface on the Infinea Tab™ M has led to increased productivity by the end users, which has allowed more orders to ship; thus, revenue to increase for their customers.

The warehouse robotics company has scaled widely once their robots were delivered and implemented at each of their customer’s site. Not only through word of mouth, but through various trade shows, the interest in the robots and the technology used within the robots has set the company on a path for tremendous growth with the help of Barcodes.

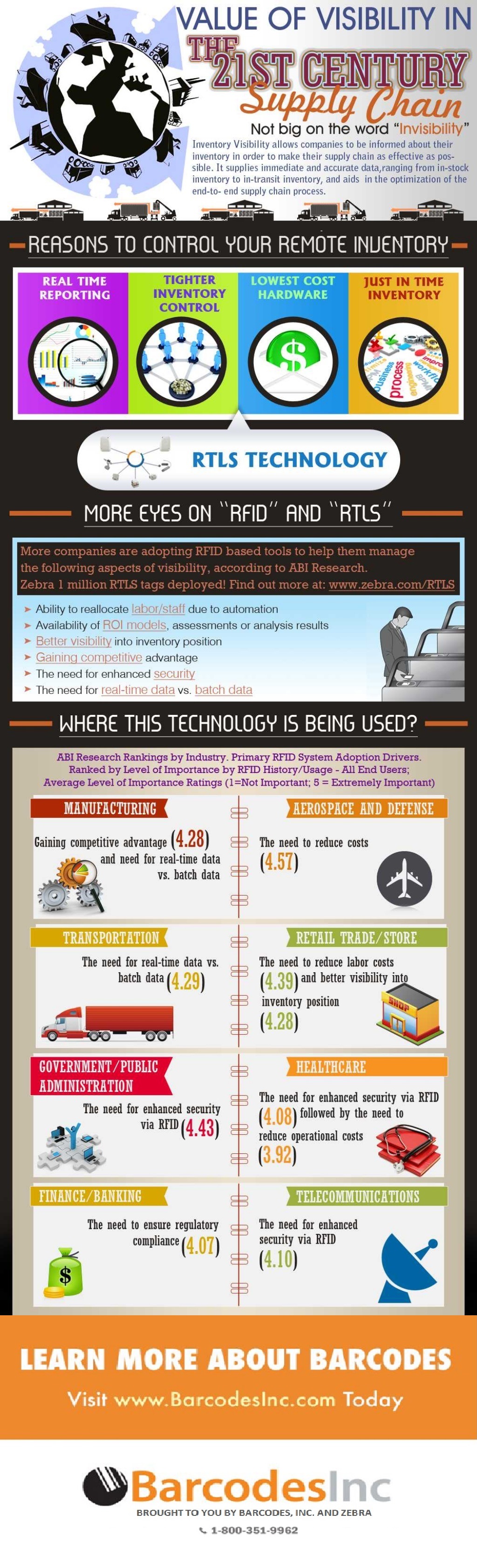

Value of Visibility in Your Supply Chain

Visibility in the supply chain is valuable data to a company. It allows company to be informed about their inventory from when it is stored or in transit in order to optimize time and allocate labor and staff.