Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

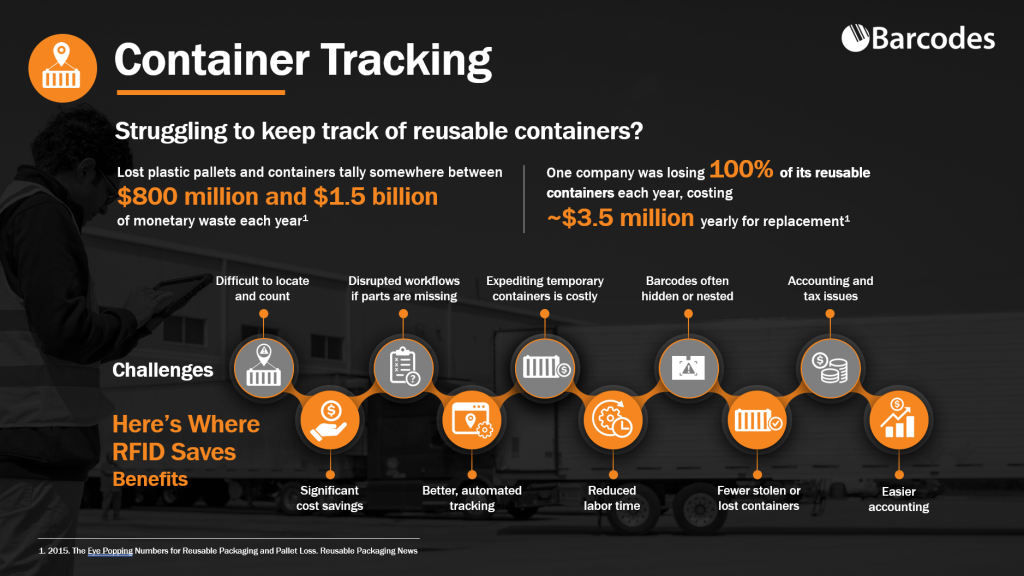

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.

The Zebra TC53 Touch Mobile Computer

Your business needs new technology to keep up with changing customer needs.

With Zebra’s TC53 mobile computer, you can collect data in a whole new way. The TC53 offers lightning-fast speeds, lots of processing power, and the most up-to-date wireless connectivity so that your teams can get to the data they need from anywhere, at any time.

It also comes with accessories that mark the beginning of a new era of mobility.

With the the TC53, your employees can do more with their computers.

TC53 Mobile Computer: The Main Benefits

The TC53 rugged mobile computer is designed for use in harsh environments and demanding applications. The latest touch solution for the enterprise runs Android, is built tough, and lasts for entire shift durations without a hiccup.

The mobile computer from Zebra is built to withstand drops, spills, dust, and other hazards that may be encountered in the field. The TC53 is also equipped with a range of features that make it well-suited for use in a variety of applications:

- Robust construction: The TC53 is built to withstand drops, shocks, and other physical impacts, making it ideal for use in rough environments

- Powerful processor: The TC53 is powered by a powerful Qualcomm Snapdragon processor, which enables fast and reliable performance

- Large display: The TC53 has a large, 5-inch display that is easy to read, even in bright outdoor conditions

- Long battery life: The TC53 is equipped with a long-lasting battery that can last for an entire shift, making it ideal for use in applications where access to power is limited

- Advanced scanning capabilities: The TC53 is equipped with a range of advanced scanning technologies, including a high-resolution camera and a long-range laser scanner, which enable fast and accurate data capture

For a detailed list of TC53 touch computer features, download the TC53 spec sheet.

See How the TC53 Touch Changes the Game

Overall, the TC53 is a rugged, feature-rich mobile computer that is well-suited for use in a variety of applications, including logistics, field service, and retail.

Contact us for a customized consultation, great prices, and rapid enterprise deployment.

Zebra ZQ600 Plus Mobile Printers Set a New Standard for Enterprise Mobility

The ZQ600 Plus mobile printers produce high-quality label and receipts anywhere, whether in the order picking fleet in the warehouse, or on the road in a delivery driver’s arsenal.

ZQ600 and ZQ610 Plus printers improve Zebra’s popular QLn platform by adding new technology and design that make them easier to use, more productive, and easier to manage.

The ZQ series printers never fall asleep on the job thanks to a feature called “instant wake-up.” Also, your mobile workforce gets the fastest and most reliable wireless connections.

Your IT department will find it easier to integrate, set up, and secure the printers thanks to Zebra’s Link-OS operating system and powerful Print DNA suite of applications, utilities, and developer tools.

It’s safe to say that the ZQ600 Series printer is the gold standard for printing labels and receipts from a mobile device.

What are the Main Benefits of the Zebra ZQ600 Plus Printer?

The Zebra ZQ600 Plus is a mobile printer designed for use in a variety of operational settings. Some potential benefits for operational leaders include:

- Rugged design: The ZQ600 Plus is built to withstand rough handling and harsh environments, making it ideal for use in field operations or other demanding settings

- High-quality printing: Each EQ600/610 Plus produces high-quality, crisp and clear prints, which can be important for producing accurate and professional-looking documents in operational settings

- Wireless connectivity: Bluetooth and WiFi make it easy to print from other devices in the field or on the go

- Customization options: The ZQ600 Plus can be customized with a range of accessories and options, such as label peelers and cutter options, to suit the specific needs of different operational settings

- Easy to use: ZQ600 printers include a simple and intuitive interface and easy-to-load media, which allows leaders to quickly and easily train new users on the printer, reducing downtime and increasing productivity

For a detailed list of features and specifications, download the ZQ610 printer spec sheet.

See the ZQ600 Plus Printer in Action

This coming year, rely on Zebra mobile printers to get the job done quickly and efficiently, anywhere your workforce goes.

Contact us to discuss your mobile label, tag, and receipt printing needs.

Four Ways to Incorporate Powered Mobile Carts in Retail

Powered mobile carts for retail eliminate the challenges of stationary point of sale infrastructure, providing the best customer experience possible. Here’s how (free infographic included below).

Are You Prepared to Adapt Your Checkout Technology?

POS in many stores tend to be anchored to checkout aisle stations. You have a monitor, printer, a handheld barcode scanner, stationary conveyor scanner, and a touchscreen payment terminal. The cash register, network, and wiring do not give you much leeway to reconfigure checkout for optimal revenue in peak shopping periods.

Customers won’t be eager to return to a checkout environment with long lines and suboptimal item scanning.

Introduce curbside pickup, e-commerce fulfillment and returns, and the need for a clear picture of inventory counts at all times – soon the need to mobilize a wireless, all-in-one checkout station becomes apparent.

4 Impactful Ways to Incorporate Powered Mobile Carts in Retail Environments

Newcastle Systems has long been an industry leader in mobile carts (picture computer, printer, scanner, and shelves on wheels with no power cords).

Powered mobile carts for retail applications are no different.

Here’s 4 ways to elevate your retail experience with powered mobile carts.

Mobilize Your Checkout and Inventory Management Today

Keep customers returning day after day with shorter lines, easy checkout, accurate stock information, and more. The NB Series from Newcastle is among many powered mobile cart solutions that does just that. Ready to learn more?

Print Receipts Anywhere Easily with the ZQ300 Plus

The ZQ300 Plus mobile printers produce high-quality label and receipts anywhere, with a user-friendly design, improved print speeds, and easier device management for operational leaders.

Zebra’s ZQ300 Plus printers give your retail team members freedom of movement anywhere on the store floor.

Mobile receipt printing enables customer sales and quicker stockroom deliveries for drivers.

With on-the-spot label printing, store employees can do markups, markdowns, and shelf label checks more quickly and accurately.

The Zebra ZQ300 Plus Series has the same features and specs as the ZQ300 Series, but it uses updated circuitry to make sure that the products will still be available in the long run.

What We Love About the Zebra ZQ300 Plus

With the ZQ300 Plus printer, you can improve the retail customer and employee experience in a variety of ways:

- Its simplicity makes it easier to train employees, with clear instructions, a beautiful onscreen display, and low learning curve

- The ZQ300 Plus printer prints personalized receipts, labels, and other materials for customers. Customers will have a more personalized and memorable experience as a result

- The ZQ300 Plus reduces wait times and increase overall store efficiency, improving the customer experience by reducing frustration and streamlining the checkout process

- Easy to maintain and clean, ensuring optimal performance and high-quality prints every time

- The ZQ300 Plus printer can be used to provide further value to customers by printing coupons or loyalty cards

For a detailed list of features and specifications, download the ZQ300 printer spec sheet.

Watch the ZQ300 Plus Printer Video

Zebra mobile printers get the job done quickly and efficiently, anywhere your workforce and customers are.

Contact us to discuss your mobile label, tag, and receipt printing needs.

Your Returns Process: 3 Simple Tips to Increase Speed & Accuracy

About this Webinar

Your Returns Process: 3 Simple Tips to Increase Speed & Accuracy

Wednesday, November 16th, 2:00 PM – 2:30 PM ET

Presented By:

Kevin Ledversis – Vice-President Sales, Newcastle Systems

Make Returns Both Faster and More Accurate

While you watch a truck departing from your shipping dock, two more are returning orders on your receiving dock! Typical scenario. Now’s the time to increase the speed and accuracy of your returns process to manage the onslaught valued at ~$800 billion in 2023.

What you will learn in this webinar:

- The basics of reverse logistics

- The obstacles that are costing you time, money, and customer satisfaction

- 3 tips to increase speed and accuracy

- Low-cost technology options, such as mobile carts, to improve your returns process now

Watch the Full Customer Returns Webinar with Newcastle

The Rise of Mobile Robotics: Exclusive Webinar

Exclusive Webinar

The Rise of Mobile Robotics

Wednesday, November 9th, 12:00 PM ET

Presented By

David Lin – Product Manager, Robotics Automation at Zebra Technologies

Manthan Pawar – Product Manager, Autonomous Mobile Robotics at Barcodes Group

About this Robotics Webinar

Labor shortage and an increase in consumer demand continue to surge the need for technological innovations that improve and automate processes. Autonomous Mobile Robots (AMRs) are the latest advancement in automation to deliver the speed and flexibility needed to fill the gaps. This webinar will demonstrate the benefits of AMRs and how they empower organizations to utilize their labor resources more efficiently.

During this webinar, we’ll be covering the following AMR topics:

- Industry drivers and trends generating the demand for AMRs

- How AMRs can help achieve higher operational speed and throughput

- AMR use cases and workflows within warehousing and distribution, eCommerce, 3PLs, and manufacturing

Watch the Full Robotics Webinar Recording

Please reach out to our team of robotics experts today.

Reasons Robotic Systems and Autonomous Mobile Robots Are Motivating Industry Leaders

Businesses and enterprises are exploring robotic systems to help them overcome challenges. Finding the balance between meeting demands and controlling costs is familiar for Fulfillment and e-commerce, distribution centers, and manufacturing. However, since the onset of the COVID-19 pandemic in 2020, companies have found that the information technology and operational technology (IT and OT) that helped them operate effectively in 2019 no longer allow them to keep up.

Robotic systems, including autonomous mobile robots (AMRs), support the intelligent, automated operations that enterprises need to stay competitive and profitable.

The Challenges Driving the Move to AMRs

Robotic systems and autonomous mobile robots give operations solutions to some of their most serious challenges.

Labor

Job openings in the U.S. have totaled more than 10 million each month from 2021 to 2022. More than 800,000 of those positions are in retail trade, and 795,000 are in manufacturing – and industry growth is outpacing available labor by a 6:1 ratio. Furthermore, businesses are not only struggling to fill positions. They are also finding it difficult to retain them.

AMRs can easily accomplish tasks in the warehouse or distribution center, such as transporting freight, replenishing parts to manufacturing lines, and transporting items or consumables to packing stations. As a result, robotic systems allow enterprises to make the best use of their labor as they automate basic tasks.

Supply Chain Disruptions

The pandemic also disrupted and slowed the supply chain worldwide. Fulfillment centers, warehouses, and distribution centers have had to respond with greater efficiency and visibility into inventory movements.

Robotic systems enable operations to move materials, cargo, or merchandise effectively to keep the supply chain moving and make the best use of warehouse capacity.

Customer Expectations: While labor shortages and supply chain issues increased, customers became more demanding. Expectations of instant, flawless service drive a greater need for speed and agility in operations.

Robotic systems work consistently and quickly to move materials, deliver them where needed, and fulfill orders accurately, increasing throughput and customer satisfaction.

The Added Benefits of Robotic Systems

Operations are deploying autonomous mobile robots to address some of today’s monumental challenges, but they’re discovering that they also provide additional advantages.

- Cost savings: With AMRs moving inventory and materials, replenishing processes, transporting recycling, and performing simple –yet time-consuming and necessary – tasks, businesses can more easily control labor and overtime costs. Operations can see significant ROI from deploying robotic systems.

- Scalability: With less dependence on labor, operations can scale with the volume of work.

- Space optimization: Many robotic systems require only a small footprint, enabling operations to utilize their space efficiently.

- Enhanced safety: Autonomous mobile robots minimize unproductive travel and are designed to prevent accidents in a busy industrial environment.

- Operational data: Because robotic systems are connected to the enterprise’s network, they can provide real-time data on their tasks, information that allows operations to digitize and catalog workflows, and insights that can help improve processes.

- Employee satisfaction: Assisted by AMRs, employees can focus on higher-value tasks and quickly complete their work.

Learn More About Robotic Systems

If deploying robotic systems and AMRs is new to your team, you can watch our full webinar with Fetch Robotics and Zebra Technologies from earlier this week.

Stages of a Successful RFID Deployment – Webinar

Webinar

Stages of a Successful RFID Deployment: From Discovery to Implementation

Thursday, October 27th, 2:00 PM – 2:30 PM ET

Presented By

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Nat Hillary – Solutions Engineer for Strategic Accounts, Impinj

About this RFID Webinar

Nearly 80% of attendees to our RFID webinars have not implemented the technology yet but are interested in exploring this. How do you determine if RFID is right for you and what steps are part of a deployment?

During this webinar, you will learn the answers to the following questions:

- Based on your unique needs, how do you determine if RFID can improve the flow of goods and inventory accuracy, and at what cost?

- Does RFID fit your organization considering your people, processes, and technology?

- How do you test reading RFID tags at your facility?

Watch the Full RFID Webinar Recording

Interested to learn more about our RFID deployment solutions and services? Contact us today for a consultation and see if it’s the right fit for your organization.

Is It the Device or the Network? A New Connectivity Webinar

About the Webinar:

Is It the Device or the Network? Gain real-time visibility into connectivity issues with Extreme Intuitive Insights.

When:

Thursday, October 13th, 2:00 PM – 2:30 PM ET

Presented By:

Paul Zastrow, Sr. Pre/Post Sales Systems Engineer | Barcodes Group

Doug McDonald, Director of Technology | Extreme Networks

Yury Ostrovsky, Senior Product Manager | Extreme Networks

About this Webinar

Connectivity issues with handheld devices plague organizations of all sizes. How do you quickly isolate and proactively flag problems affecting Wi-Fi connectivity, roaming, application performance and voice execution? New cloud-based applications, such as Extreme Intuitive Insights, provide operational insights without the need to chase down physical devices to test and troubleshoot.

This webinar and demonstration will teach you how IT teams:

- Gain visibility into issues caused by the network versus the Zebra devices using the network

- Leverage the cloud to reduce time to analyze with limited staffing and resources

- Identify devices that may have left the facility, been lost, or stolen with Geofencing

Watch the Full Webinar Recording