RFID Webinar: Improve Returnable Container Tracking with RFID

Webinar

Improve Returnable Container Tracking with RFID

Thursday April 20th 1:00-1:45pm Central

PRESENTED BY:

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Michael Daily – Senior Solutions Engineer, Impinj

RFID-Based Container Tracking

Upon delivery, it’s common for reusable containers to not be returned to the sender, with annual shrinkage rates often exceeding 10%. Keeping track of your Returnable Transport Items (RTIs) can be challenging, especially when logging their location depends on manual processes like scanning.

In this webinar, discover the benefits of RFID-based container tracking:

- Reduce the number of misplaced pallets, kegs, and boxes. Less new delivery assets need to be purchased, and shipments are not interrupted due to lack of totes.

- Track each asset as it leaves and returns to the warehouse, allowing you to determine its exact location immediately and whether they have yet to return.

- Calculate the flow of returnable assets to fully understand your shipping capacity for the present and future.

- Improve utilization of workers since it takes way less time to scan RFID tags than barcodes, due to its fully automatable reading without line-of-sight requirements.

Watch the Full RFID Webinar Recording

Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

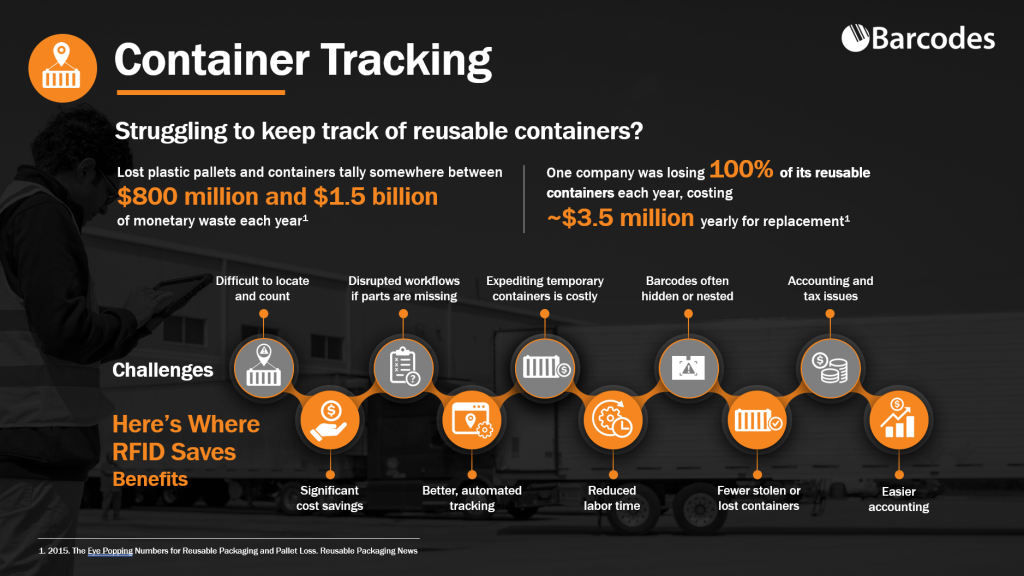

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.

Where to Place an RFID Inlay

Printing and encoding RFID “smart labels†with an RFID-enabled printer has traditionally been difficult; a classic case of “the Devil is in the details.â€â€¯ One difficulty users have wrestled with has been “inlay placement.â€â€¯ Inlay placement refers to the location of the RFID inlay under the label’s face stock.  Although inlays are generally oriented horizontally under the face stock, the inlays can be located towards the bottom of the label, towards the top, or anywhere in between.  In the picture to the right, for example, the inlay is relatively close to the bottom of the label, the “leading edge†as it is often called, because this edge comes out of the printer first.

Almost every printer brand – and even model – has traditionally had detailed, complex specifications regarding inlay placement, with different specifications for each and every inlay on the market.  The location of the inlay has to be a particular distance from the leading edge of the label in order to maximize the printer’s throughput (speed).  Just a millimeter or two either way, and the performance of the printer can suffer dramatically.  What a mess.  Given that printing and encoding RFID labels is already slower than printing traditional barcode labels, any further loss in performance has often been catastrophic for the end-user.  Waiting for your RFID labels to print and encode can hold up an entire production line.  This all meant that for your printer brand and model, you needed to make sure to order labels with an optimal inlay placement.

Precise inlay placement also causes some additional problems:

- It makes selecting labels more difficult. Users need to order their labels very carefully to ensure correct inlay placement.  Does your purchasing department understand inlay placement?

- It can cause delays in sourcing labels.  Often, a convertor (label manufacturer) will have exactly the label size you need – but with incorrect inlay placement for your printer.  To get labels with optimal inlay placement, the convertor needs to configure their entire production line and run a new batch of labels for you.  This can take several days to several weeks.

- Finally, requiring a specific inlay placement can mean that users may pay more for their labels.  A quick Google search of classic paper thermal transfer 4×6 RFID shipping labels will show some surprising results.  The very same labels from the very same vendor can have dramatically different prices depending solely on inlay placement.  It all boils down to supply and demand, but if you are on the wrong side of the equation, you may have to pay significantly more for your labels.

With Printronix Auto ID’s current line-up of RFID printers, these headaches associated with inlay placement are now a thing of the past.  Printronix RFID printers have a unique firmware (the software brains in the printer), which does what they call “Encode During Print.â€â€¯ In clearer language, this means that the printer will first print some of the label, then switch over to encoding, then switch back to printing and finish up the label.  The printer will automatically either print or encode at any given moment depending on where the label is relative to the printer’s printhead and RFID encoder.  The traditional approaches for RFID printers were to either first print the entire label, then encode the RFID portion (“Print then Encodeâ€) – or to first encode the RFID, then print the label (“Encode then Printâ€).  But with these traditional approaches, if the inlay is not optimally placed, then the printer needs to back- or forward-feed the label to align it for an operation (printing or encoding) at any given moment.  With Printronix’s Encode During Print functionality, back- and forward-feed are eliminated (other than to overstrike bad labels, which is another blog topic for another day), regardless of inlay placement.

So far, we have been talking about labels like 4×6 shipping labels that allow different inlay placements.  But what about all of the RFID labels, “tags,†on the market that have predetermined inlay placement?  For example, on-metal tags, plant stakes, small pharmaceutical labels for cold-chain applications, “RTI†tags (Returnable Transport Items), etc., etc.  There are many such tags on the market, and more are being developed and released all the time.  These tags generally have a fixed inlay placement based on their physical design and on simple commercial considerations – they are meant to be “Off-the-Shelf†(OTS) products.  This is another area Printronix’s Encode During Print functionality shines even more.  Because the Printronix printers do not care where the inlay is located, you can use any of these tags and still achieve maximum throughput.

And these unusual tags often pose physical feed challenges for RFID printers. For example, on-metal and RTI tags are often thicker than normal smart labels, and they can have abrupt edges between labels, large gaps, etc. Both Printronix’s T6000e and T4000 series printers were designed from the ground up to work with these more difficult constructions.  The printers are spec’ed for labels up to 1.2mm thick and are available in 4†and 6†print-widths, allowing you to print and encode a wide variety of tags from a single printer – all without sacrificing performance.

Finding the right RFID solution is always a challenge and having the right resources and help are critical. If RFID sounds like a suitable solution for your business or you have additional questions, feel free to contact us at Barcodes, Inc. We’re always happy to help you find the right solution for your needs.

The Next Generation 4-inch Desktop Thermal Printer

Setting the bar for desktop barcode label printing, SATO’s CT4-LX is a 4-inch thermal printer offering features and functionality typically only found in industrial printer models but in a compact size. Designed with a full-color touchscreen display, the latest wireless connectivity options and patented label waste prevention feature, the CT4LX Label Printer is easy to operate and maintain with user-replaceable printheads and platen rollers to quickly keep your business up and running.

Key Features

– 4.3″ Full Color Touchscreen Display

– 203 or 305 dpi print resolution

– Thermal Transfer and Direct Thermal

– Label Waste Prevention – eliminates first label loss

– Apple iOS Connectivity

– Quick pairing with NFC-enabled devices

– Auto Switching competitive emulation languages (SBPL, SEPL, SZPL, SDPL, SIPL, or STCL)

– Auto RFID positioning with SATO RF Analyze (SRA)

– Remote management with SATO Online Services (SOS)

Connectivity Options: USB, Ethernet, Wi-Fi, Bluetooth, RS-232C

Optional Features: UHF RFID encoder (pre-installed), Auto-Cutter, Linerless Cutter, Dispenser, Real-Time Clock

Shop the Sato CT4-LX online or Contact your Barcodes, Inc. Account Manager for more information.

A Zebra Printer for the Right Job

At Barcodes, Inc our extensive Zebra portfolio boasts industry-leading printer products. With Zebra’s Barcode and RFID printer solutions you’ll have a printer capable of smarter ways to track labels and manage assets with the ability to produce labels, receipts, documents, or cards on-demand. Are you optimizing your printer’s efficiency? Are you using the right Zebra Printer for the right job?

The ZXP Series 9 card printer has selectable print modes that’ll allow users to easily optimize for print quality or print speed. The new fine print mode slows the printing process down slightly in order to deliver photo-like image quality. Reduce printer downtime with Near Field Communication technology and QR Codes that give you instant access to printer information and support. With the ZXP Series 9 card printer the user will have the ability to view printer settings, status, and manage a large number of networked remote printers from anywhere in the world using Zebra’s optional PrintMonitor. The ZXP 9 is ideal for government, retail, hospitality, education, and service bureaus.

The ZXP Series 9 card printer has selectable print modes that’ll allow users to easily optimize for print quality or print speed. The new fine print mode slows the printing process down slightly in order to deliver photo-like image quality. Reduce printer downtime with Near Field Communication technology and QR Codes that give you instant access to printer information and support. With the ZXP Series 9 card printer the user will have the ability to view printer settings, status, and manage a large number of networked remote printers from anywhere in the world using Zebra’s optional PrintMonitor. The ZXP 9 is ideal for government, retail, hospitality, education, and service bureaus.

The HC100 Wristband Printer makes it easy to print individual wristbands on demand. All users have to do is drop in the wristband cartridge and start printing high-quality wristbands. With an easy-to-load feature, minimal action is required from the user. The printer detects the wristband type and size and will automatically calibrate the settings for optimal print quality and reduce waste. With faster print speeds, wait lines at the point of entrance are reduced, improving the customer experience and staff productivity. The HC100 is ideal for hospital patient identification as well as guest identification at hospitality venues, amusement parks, sporting events, zoos, etc.

The HC100 Wristband Printer makes it easy to print individual wristbands on demand. All users have to do is drop in the wristband cartridge and start printing high-quality wristbands. With an easy-to-load feature, minimal action is required from the user. The printer detects the wristband type and size and will automatically calibrate the settings for optimal print quality and reduce waste. With faster print speeds, wait lines at the point of entrance are reduced, improving the customer experience and staff productivity. The HC100 is ideal for hospital patient identification as well as guest identification at hospitality venues, amusement parks, sporting events, zoos, etc.

The ZQ500 Series are a set of rugged mobile printers. With the ability to withstand repeated drops to concrete from up to 6.6 feet (2 m). The mobile printers come with large buttons and a user-friendly interface making it easy to operate. The ZQ500 series comes in two options the ZQ510 3 inch (72 mm) and the ZQ520 4 inch (104 mm). The set of mobile printers meet IP54 rating for resistance to dust and liquids that are common in mobile environments. The ZQ500 series is ideal for transportation, retail, and manufacturing.

The ZQ500 Series are a set of rugged mobile printers. With the ability to withstand repeated drops to concrete from up to 6.6 feet (2 m). The mobile printers come with large buttons and a user-friendly interface making it easy to operate. The ZQ500 series comes in two options the ZQ510 3 inch (72 mm) and the ZQ520 4 inch (104 mm). The set of mobile printers meet IP54 rating for resistance to dust and liquids that are common in mobile environments. The ZQ500 series is ideal for transportation, retail, and manufacturing.

Zebra’s Silverline On-Demand RFID Metal Asset Tagging Solution

Zebra and Confidex have worked together to develop this unique solution consisting of a redesigned ZT410 RFID printer, optimized Silverline labels and high quality Zebra ribbons. This combination provides for excellent print quality, encoding accuracy and ease of solution deployment and use. Silverline labels, now offered exclusively by Zebra, are available in three sizes to meet the needs of a wide variety of applications. When combined with Zebra’s RFID reader portfolio, the launch of Silverline enables complete Zebra RFID solutions for the most critical Enterprise Assets. For example in healthcare, hospital assets like wheel chairs, beds, oxygen canisters, IV pumps, medical diagnostic instruments, etc. can now be accurately and efficiently RFID tagged. In manufacturing, it enables tagging of tools, fixtures, metal parts, returnable containers, etc. Tagging of IT assets such as laptops, servers, tablets, etc. is another ideal use case.

Zebra and Confidex have worked together to develop this unique solution consisting of a redesigned ZT410 RFID printer, optimized Silverline labels and high quality Zebra ribbons. This combination provides for excellent print quality, encoding accuracy and ease of solution deployment and use. Silverline labels, now offered exclusively by Zebra, are available in three sizes to meet the needs of a wide variety of applications. When combined with Zebra’s RFID reader portfolio, the launch of Silverline enables complete Zebra RFID solutions for the most critical Enterprise Assets. For example in healthcare, hospital assets like wheel chairs, beds, oxygen canisters, IV pumps, medical diagnostic instruments, etc. can now be accurately and efficiently RFID tagged. In manufacturing, it enables tagging of tools, fixtures, metal parts, returnable containers, etc. Tagging of IT assets such as laptops, servers, tablets, etc. is another ideal use case.

Silverline Solution:

• Total Solution: Silverline RFID tags and Zebra ZT410 Silverline printer

• Provides RFID labels that work directly on all surfaces

• Prints and encodes labels for metal and liquid-filled assets

• Choose from three types of RFID labels: standard, slim and micro

• Available Globally

• Read range of up to 5m

• Reliable, flexible and scalable

The Internet of Things with Zebra and Barcodes, Inc.

What is it?

What is it?

The Internet of Things (IoT) is the coming connectivity of everything you own, everything you see. No longer will access to the internet be limited to single point interfaces like your phone or computer, or single-point data sources like web pages or servers. Nor will it be limited to you! Everything you see can, and someday will, be interconnected and sharing data: your tv, your refrigerator, your home, your car, the roads you drive on, the building you work in, the package you’re delivering… everything.

So far, the Internet of Things has been most closely associated with machine-to-machine (M2M) communication in manufacturing and power, oil and gas utilities. Products built with M2M communication capabilities are often referred to as being smart.

Why do I care?

IoT will affect the way we live and work. IoT will impact every industry out there: Healthcare, Manufacturing, Transportation & Logisitics, Retail, Hospitality, Warehousing, and so on. Your competitors will be embracing IoT capabilities to find a competitive advantage, the same advantage you want to get first. The advantage that comes with speed, efficiency, and a clear view of your assets and operations, your people and inventory, 24/7 in real time.

Zebra’s Compact, Easy-to-Use UHF RFID Printer the ZD500R

The new ZD500R extends Zebra‘s broad range of RFID printers by adding UHF RFID printing and encoding to Zebra’s line of industry-leading  compact thermal desktop printers. Designed for applications where space is at a premium, the ZD500R offers simple, one-touch printing and encoding, straightforward loading, and automatic RFID calibration, making it ideal for applications where technical support staff is limited, such as retail in-store exception tagging.

The printer supports both direct thermal and thermal transfer printing and is compatible with inlays from all leading suppliers. The ZD500R can be used with a variety of RFID labels and tags from small, item-level hang tags to large case and pallet labels. By encoding RFID inlays that are spaced closer together, the ZD500R enables lower media costs, less media waste and fewer roll changes.

Zebra RFID Printer Infographic

Gaining the all the benefits of RFID normally involves turning your standard printed label into a RFID enabled one. Most RFID labeling solutions still utilize barcodes and other printed details on the front of the label for redundancy in case a tag were to get damaged, so finding a reliable RFID printer also means choosing a good barcode printer at the same time.

With the ever expanding options for RFID printers it can be a challenge finding one that suits your application without costing a fortune. Lucky for us, one of the leading manufacturers of barcode printers, Zebra, also makes a full line of RFID printers of the same high caliber. Whether you need a high volume industrial solution, a mobile in-the-field option, or a basic low-volume economical solution, Zebra has an RFID printer to fit any need.

This infographic is a great primer into the Zebra line and you can always contact us at Barcodes Inc. with any questions or need for assistance in choosing the right unit for your business.

Printronix RFID Printers

As RFID becomes a more commonplace tool to help all types of businesses become more efficient and accurate, the available choices for RFID printers is expanding all the time. Given the costs involved you obviously want to find a printer that will meet any compliance/performance requirements you need while being a reliable  investment for the long term.

Printronix has been a leading manufacture of industrial grade label printers and continues this legacy with their current line of RFID printers. Designed for the most demanding and critical applications, the SL5000R and SL4M are the perfect solutions for any RFID printing requirement.