Improve Returnable Container Tracking with RFID

Returnable Transfer Items (RTIs), or returnable containers are critical assets for almost all manufacturing and logistics organizations. RTIs transport stock and commodities from one site to another. However, keeping track of your RTIs is a different story. Well-known manufacturers and logistics expert still often rely on manual methods, such as traditional scanning, spreadsheet, or pen and paper.

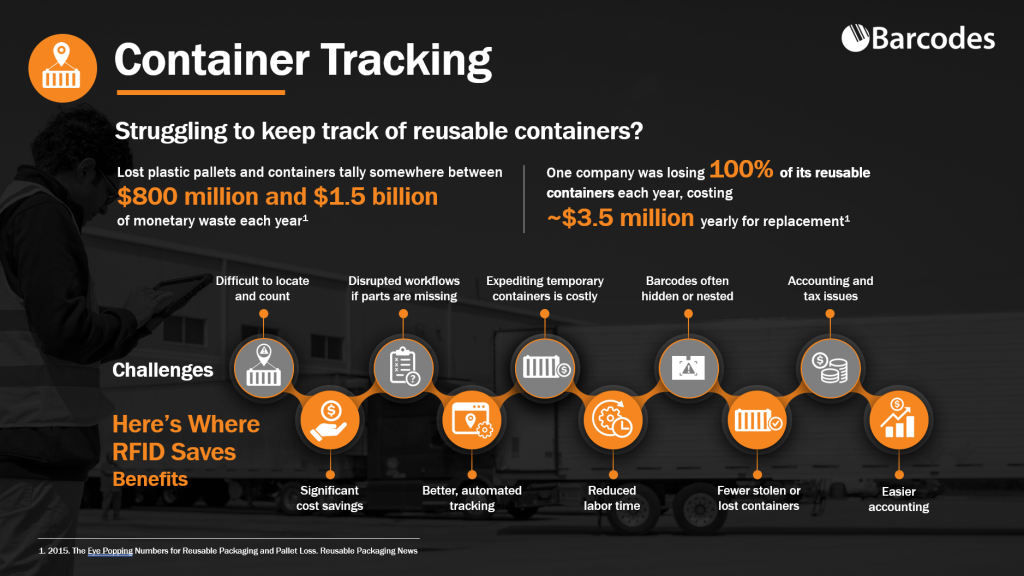

This leads to a major issue: inventory shrinkage.

Mismanagement of returnable containers owing to theft, unrecorded damage, or simply the inability of consumers to return empty pallets, kegs, and boxes costs a fortune.

How are Your Returnable Transfer Items Being Tracked Currently?

Barcode labels used to tag the cargo of a container during shipment are often non-permanent. Traditional barcode scanners and labels identify the contents of the container, but seldom provide reverse logistics tracking for the containers themselves.

Using permanent barcode labels as the foundation for a container monitoring system is not feasible. I know that might be strange to hear from a company called Barcodes, Inc. But scanning labels at various stages of the supply chain sometimes necessitates extra human effort, which is even more difficult when empty containers pile up.

One solution is to establish a tracking system utilizing modern asset tracking technology.

Reducing Yearly Inventory Shrinkage with RFID

“15% of all pallets in circulation vanish” or “20% of all packaging/equipment is lost owing to consumers retaining them for their own use or third parties removing them for their own use.”

SLS RFID 2016 Study

Inventory shrinkage is a major issue in the management of returnable transfer items (RTIs), which include all types of shipping containers, packaging, pallets, kegs, and boxes.

Shrinkage due to theft, unreported damage, or just consumers failing to return empty containers is a serious concern in this field.

Estimated annual shrinkage rates are anywhere from 3 to 9%. If you’re constantly replacing lost or stolen RTIs, the impact on profitability is a huge problem.

For organizations to decrease RTI shrinkage, RFID is appealing due to completely automated scanning without line-of-sight, as well as mass tag reading. The key advantage of RFID-based container monitoring systems is an improvement in container return rates. New containers are purchased in smaller batches and less frequently.

What Data Can Be Tracked with RFID Tags?

Integrating the RFiD Discovery system with your ERP system enables company-wide visibility of your RTIs, ensuring that essential assets are accessible at the relevant locations to fulfill any transportation request.

Exactly what the RFID ultimately tracks depends on your unique tracking requirements. Here are some examples of the depth of data you can store in a small RFID tag:

- Container Name

- Size

- Location

- Weight

- Item Quantity

- Container Properties

User memory on tags stores data. The serial number field can be pre-programmed or user-assigned.

The air-interface protocol standards for passive HF and UHF tags, such as UHF EPC Gen 2, define basic functions like read-write and which memory banks or blocks can be written to. Reader manufacturers include these low-level commands with higher-level subroutines in their software development kits for application developers.

How to Use RFID to Tag RTIs

RFID labels are long-lasting and more durable than traditional labels. RFID tags attach exceptionally well to returnable cargo and resist machine washing operations as well as harsh elements for much longer.

Any RTI equipped with an RFID tag can be detected by a small number of strategically located readers. The location data is delivered back to the central RFID Discovery database, where it may be evaluated.

This database allows you to discover how many RTIs have been sent to a specific supplier or customer, so you know which trade partner to approach when requesting a return.

When shipping containers are in range of an RFID reader, the information on the tags can be automatically acquired using a wide variety of methods:

- Fixed reader installed at a warehouse entrance or loading dock

- A mobile reader installed on a forklift

- Handheld reader brought inside a business partner’s facility for rapid inventory

What are the Main Advantages of Using RFID for Returnable Asset Tracking?

There are several advantages of using RFID to track returnable assets.

1. Recoup Billions of Dollars in RTI-Related Losses

Reusable assets are returned to the sender after delivery, usually full of new goods and not empty. Entire industries are dedicated to capitalizing on reverse logistics and maximizing the value of containers.

So why do we pay far less attention to reusable assets compared to sold commodities and container space? In order to get a bird’s eye view of costly shrinkage areas, your immediate shipping capacity, and overall supply chain health, it’s critical to assess the flow of returnable assets as well.

If RTIs arrive in the incorrect place or are lost, the transfer of products becomes difficult or impossible, thereby causing delivery delays. And massive container replacement costs.

These misplaced assets represent billions of dollars in losses, since new delivery assets must be acquired. We will say again: RFID saves billions of dollars.

2. Track Every Asset Location With a Detailed Evidence Trail

While we like to imagine most people are honest and good by nature, the reality is that customers and suppliers are not going to eager to assist when the subject of locating your missing valuables is brought up. Tough luck.

Instead of playing the blame game, utilizing an RFID system to track each asset as it leaves and returns to the warehouse allows you to instantly establish its specific location, and whether it has yet to return.

This goes for both goods sold as well as the RTIs carrying them. Put another way, your returnables are much more likely to return.

3. Increase Visibility of Container Locations, Available Stock, and Overall Condition

Though shipping should be a precise science, we know that’s not always the case.

Businesses depend on RTIs everyday, but lack visibility over the availability, location, and quality of their RTIs.

When organizations incorporate careful pallet monitoring, tote box tracking, and stillage tracking, it’s much easier to manage a large pool of RTIs without bleeding money. Additionally, there is no longer a need to keep just-in-case containers on the sidelines, because of increased visibility into the “who, what, where, and how many?” questions.

4. Improve Labor Utilization at Every Level of the Supply Chain

Scanning RFID tags takes substantially less time than scanning barcodes. Similarly, RFID is a more appealing identifying solution for reusable assets since users do not need to manufacture new barcodes or print new labels.

Logistics and operational leaders can simply re-encode the same RFID tags again and again without increasing headcount or allocating redundant processes to busy workers.

Lastly, RTLS on RFID can significantly reduce the amount of time workers spend searching for specific inventory. In a field such as healthcare, nurses estimate they spend at least an hour per shift finding equipment. That really adds up when looking at overall labor utilization.

Evaluating and Deploying an Effective RTI Tracking System

Tracking RTIs with RFID helps prevent your assets getting lost or stolen, reduces disputes between trading partners, enables rapid inventory cycle counting, and quickly identifies shortages. Your organization could be saving billions of dollars.

Barcodes, Inc. is your trusted RFID partner and integrator. Contact us when you are ready to elevate your RTI management and discover the magic of RFID tracking. It’s easier to deploy with a partner you can trust.