Newcastle NB Power Cart: Get the Most from Your Label Printers

So you just invested in an industrial label printer for the warehouse. Before you dedicate a table and workstation where it will print labels in one place for eternity, read this.

Printer Placement is Key

Consider strategically placing your equipment on a Newcastle Power Cart, such as the NB300NU2, which is trusted by industry leaders like Walmart, DHL, Tesla, UPS, and Wayfair.

By integrating your label printer with a Newcastle Power Cart, you enable your employees to print labels directly on the pallet, effectively doubling output while significantly reducing errors. This seamless integration ensures that your employees have access to all resources, increasing productivity and reducing costly errors by up to 92%.

Newcastle NB Series Power Carts Pay For Themselves in 6 to 8 Months

The Newcastle NB300NU2 not only simplifies label printing but also streamlines workflow processes, resulting in a remarkable twofold increase in worker output. With this innovative solution, workers no longer need to travel to a distant printer, freeing up their time to focus on important tasks.

Investing in a Newcastle Power Cart like the NB300NU2 provides an excellent return on investment, with most businesses seeing payback within six to eight months of implementation. By consolidating resources and improving operational efficiency, the Newcastle Powered Cart proves to be a valuable asset in increasing throughput while lowering payroll costs.

Integrating your label printer with a Newcastle Power Cart will improve printer performance, period. This powerful pairing ensures increased productivity, fewer errors, and a faster return on investment, allowing your team to accomplish more while maintaining operational excellence.

For a detailed list of features and specifications, download the NB300NU spec sheet.

See the NB Powered Mobile Cart in Action

Contact us today to see how a mobile workstation from Newcastle can reduce redundant movement and inefficiencies in your operation.

For Improved Efficiency, Consider Newcastle’s PC Series Mobile Workstations

How do you increase throughput, shorten order cycle times, and maximize labor productivity, all while maintaining order accuracy in the warehouse? It doesn’t have to be a complicated, high cost challenge. A rugged industrial scanner and printer workstation often solves these issues on its own.

The problem: most dedicated workstations are stationary in one area of work. Imagine a workstation that you can easily cart around. With unparalleled mobility, PC workstations from Newcastle provide extra space for a laser printer, supplies, inventory, and more.

Newcastle Mobile Powered Carts let you tackle all these issues at the same time in a cost effective manner. By bringing your displays, mobile computers, and label printer to the pallet, you eliminate hours of back and forth in the warehouse.

Observe the PC Series Mobile Workstations in an Operational Environment

Key Features of the PC Series Workstation

- Mobile Workspace: Choose from a 30″ or 48″ tabletop, offering ample space for your laptop and paperwork

- High Carrying Capacity: Durable design with a remarkable 400 lbs. load capacity

- Precision Movement: Our specialized casters ensure smooth and accurate mobility, even when fully loaded

- Expandable Tabletop: Add our folding shelf accessory to expand the tabletop to a spacious 66″ x 24″ (11sf in total)

- Battery Options: Available in both lightweight Lithium and SLA battery variants

For a full list of detailed information, download the PC Series spec sheet.

Contact us today to see how a mobile workstation from Newcastle can reduce redundant movement and ineffiencies in your operation.

Four Ways to Incorporate Powered Mobile Carts in Retail

Powered mobile carts for retail eliminate the challenges of stationary point of sale infrastructure, providing the best customer experience possible. Here’s how (free infographic included below).

Are You Prepared to Adapt Your Checkout Technology?

POS in many stores tend to be anchored to checkout aisle stations. You have a monitor, printer, a handheld barcode scanner, stationary conveyor scanner, and a touchscreen payment terminal. The cash register, network, and wiring do not give you much leeway to reconfigure checkout for optimal revenue in peak shopping periods.

Customers won’t be eager to return to a checkout environment with long lines and suboptimal item scanning.

Introduce curbside pickup, e-commerce fulfillment and returns, and the need for a clear picture of inventory counts at all times – soon the need to mobilize a wireless, all-in-one checkout station becomes apparent.

4 Impactful Ways to Incorporate Powered Mobile Carts in Retail Environments

Newcastle Systems has long been an industry leader in mobile carts (picture computer, printer, scanner, and shelves on wheels with no power cords).

Powered mobile carts for retail applications are no different.

Here’s 4 ways to elevate your retail experience with powered mobile carts.

Mobilize Your Checkout and Inventory Management Today

Keep customers returning day after day with shorter lines, easy checkout, accurate stock information, and more. The NB Series from Newcastle is among many powered mobile cart solutions that does just that. Ready to learn more?

Your Returns Process: 3 Simple Tips to Increase Speed & Accuracy

About this Webinar

Your Returns Process: 3 Simple Tips to Increase Speed & Accuracy

Wednesday, November 16th, 2:00 PM – 2:30 PM ET

Presented By:

Kevin Ledversis – Vice-President Sales, Newcastle Systems

Make Returns Both Faster and More Accurate

While you watch a truck departing from your shipping dock, two more are returning orders on your receiving dock! Typical scenario. Now’s the time to increase the speed and accuracy of your returns process to manage the onslaught valued at ~$800 billion in 2023.

What you will learn in this webinar:

- The basics of reverse logistics

- The obstacles that are costing you time, money, and customer satisfaction

- 3 tips to increase speed and accuracy

- Low-cost technology options, such as mobile carts, to improve your returns process now

Watch the Full Customer Returns Webinar with Newcastle

Newcastle Mobile Powered Carts: Getting Products to Customers Faster

These are tough times to run a warehouse. How do you increase throughput, shorten order cycle times, and maximize labor productivity, all while maintaining order accuracy?

Newcastle Mobile Powered Carts let you tackle all these issues at the same time in a cost effective manner. By bringing your printer to the pallet, you slash time walking.

What’s more powerful than a rugged industrial scanner station in the warehouse? One that you can easily cart around thanks to modular power carts from Newcastle.

See the NB Mobile-Powered Carts in Action

Contact us today to see how you can initiate a warehouse solution for maximum productivity and efficiency.

Newcastle MK LT Series DS0121 Cart

Sometimes, you just need a mobile computer cart to get the job done right.

The MK LT Series DS0121 from Newcastle Systems is inexpensive, lightweight, and has the potential to increase output by at least fifty percent.

The DS0121 is our most cost-effective mobile cart system to date, and it was designed specifically for mobile computer and light printing applications in commercial and industrial settings.

The elimination of costly footfall to and from static hardware results in noticeable productivity gains for your workforce. Using the mobile trolley, a laptop, thermal printer, and scanner can be powered all at once. That means fewer redundant trips, and fewer instances where scanners run out of charge.

The amount of energy, time, and money saved when you implemented a powered mobile cart makes for an exceptional price to performance ratio.

Reasons to Love the LT DS0121 Mobile Cart

- Typical return on investment attained in less than three months

- Rugged industrial design for improved performance and longevity in the harshest environments

- Lightweight for any worker to push easily, weighing in at just 63 pounds

- Compatible with existing hardware – just plug and go

- Quiet, seamless AC Power

Endless Customization Options for Your Specific Needs

Standard LT Series carts all include a top shelf, middle shelf, and push handles as well as 5″ rubber wheels and locking industrial casters. Beyond these features, LT mobile carts have nearly endless ways to customize them depending on your operational needs.

For one, adjustable laptop and scanner holders can be included on each mobile workstation.

You also have a wide range of battery power options. Most popular is a reusable, lightweight lithium iron battery that will run 24/7 and is easily swappable (or can be installed as a “fixed” battery). Sealed lead acid batteries that run for 8+ hours are another power choice that many warehouses rely on.

Another feature we love is the Bluetooth-enabled app, which displays charge level, cycle life, and more usage statistics (available for Android and Apple).

See the LT DS0121 Mobile Cart in Action

For more detailed information: [Download the LT DS0121 Mobile Cart Spec Sheet]

Don’t wait on the LT Series. The ROI gains far exceed the modest price tag.

If you think a mobile cart system would be useful in your work environment, please contact us. A representative can point you towards the best mobile cart solution for your needs.

Mobile Labeling Stations from Newcastle Systems Drastically Improve Warehouse Efficiency

Warehouse and fulfillment operations pose a great challenge any year, but consumer behavior during the pandemic has shifted heavily to online purchases. As a result, operations are handling larger inventories and more receipts, picks, shipments, and returns than ever before.

Meet the Demands of eCommerce Growth

While organizations focused on “keeping up” with demand, this was often at a higher cost (especially since many deprioritized process inefficiencies).

The eCommerce trend is not short-term. In Q1 2020, U.S. ecommerce sales climbed 39% over the same time last year, and growth projections already are nearly two years ahead of forecasts.

With demand still high, any inefficiencies in your processes will be exaggerated (and hence, more costly). Higher costs could mean serious limitations when scaling up your operations.

To optimize your warehouse for growth, small steps can make big impacts on your bottom-line costs, profit margin, even productivity – without significant investment in time, budget, or fancy software.

Ready to trim waste from your eCommerce operations? Get quick results with these five steps:

#1 – Establish a Cleaning Routine for Your Warehouse

Never underestimate the power of “clean.” Dust and dirt can damage product; empty pallets take up valuable space; and scrap boxes and strewn paper become obstacles and potential safety hazards that impede machine and people access, reduce productivity, and add extra steps as workers maneuver to avoid roadblocks. Implement an ongoing “clean routine” task list for your warehouse to streamline traffic and protect product – and workers.

#2 – Save Valuable Time with Cross-Docking

In eCommerce, there is a lot of pressure to ship items fast. If you have back ordered or single-item orders for certain products, you can save valuable time by skipping the restocking process. Instead, set up a process to relabel them for shipping right as they come off the truck on the receiving dock, and route them right back out the door of your shipping dock.

#3 – Simplify the Labeling Process

Labels have been around for decades, quietly getting inventory from point A to point B. Despite their importance, labels are perhaps one of the most underappreciated aspects of warehouse operations – and potentially one of the least efficient. Take time to audit and map your labeling process, paying particular attention to wasted motion, for example, the number of mouse clicks it takes to adjust formats, the number of trips a worker takes to/from the printer. Try to reduce the extra steps and work toward achieving an ideal mobile labeling process of Scan, Print, Apply. Mobile labeling stations, such as the Newcastle NB Series Nucleus System, help reduce walking and double employee productivity.

#4 – Organize SKU Location According to Volume

Certain items in your inventory may be more popular than others. For SKUs with higher order volumes or seasonal spikes, making them more accessible also makes processes more efficient. Location is key, so prioritize these items by placing them closer to packing for instance – and don’t forget to increase the bin size so stock doesn’t run low.

#5 – Reduce the Steps Required to Fill Orders

It may be hard to believe, but simply reducing the physical number of steps an employee takes to fill an order can result in significant cost and time savings. Converting a stationary workplace to a mobile one is the easiest, most economical way to increase the productivity of your current workers and infrastructure. Powered industrial carts, such as the line of products from Newcastle Systems, can hold and power printers, computers, and more to remove the tethers of a stationary workstation. This is everything workers need to get the job done right at their fingertips.

Improving Warehouse Efficiency

Efforts to optimize warehouse processes don’t have to be time-consuming or expensive. And doing so improves warehouse efficiency, and enables you to scale your operations successfully along with ecommerce growth. Whether you have interest in a specific solution from Newcastle, or have questions about general warehouse efficiency, don’t hesitate to contact us.

Newcastle Systems MotionMeter

Why MotionMeter?

What is WASTE?

WASTE is any task in a process that is not required to complete a process successfully. When waste is removed, only the tasks that are NECESSARY to deliver a satisfactory product or service to the customer remain in the process.

Wasted Motion does not happen all at one time – it may be 20 seconds here and 10 seconds there, making it extremely difficult to identify. Simple examples of wasted motion include:

- Walking to a printer to print labels

- Walking to a computer to access data

- Walking to a static desk to dimension product

Not only is this waste hard to identify, it’s also very costly over the course of a year.

What value does MotionMeter provide?

MotionMeter by Newcastle Systems is a free user-friendly app (available for both Apple and Android devices) that enables you to quickly perform your own time studies by capturing the time of core processes within your business. It can help you identify which step of the process is NECESSARY (Value Add) or WASTE (non-Value Add).

It’s also an ideal tool to capture data of specific steps (or tasks) in lieu of performing a full-scale process time study.

From there, a comprehensive overview will outline how much the wasted motion is costing your business and how much you could save annually if that motion is eliminated.

Contact Barcodes, Inc. to understand what your savings might look like.

How Newcastle Systems Mobile Workstations Cut Receiving Times by 52%

Saving time and improving warehouse efficiency is a top priority for businesses. The typical receiving process can take 20.75 minutes – but with Newcastle Systems mobile workstations you can cut that by 52% and save 520 hours per user per year!

How to Streamline Warehouse Receiving

How much wasted time and tasks could your warehouse cut out with a mobile workstation that moves with your workers?

- Walking from the receiving area to the computer to look up order details

- Waiting to print orders

- Walking back to the products

- Walking back to the computer to print labels

- And more

Instead, a Newcastle workstation with its own container computer, printer, barcode scanner, and power source can move to your receiving station and allow your workers to scan, inspect, print, and apply labels right on the spot.

Shop Newcastle Workstations

Mobilize your workstation to anywhere in the warehouse with Newcastle Systems. Durable and customizable, these stations have everything you need. Compact stations fit into narrow isles and smaller warehouses, and battery options can power your devices for an eight-hour shift.

Barcodes, Inc. carries a wide range of Newcastle Systems mobile workstations including the NB series, the PC Picking series, the RC Utility series, NB Slim series, and EcoCart series along with accessories, parts, and power packs.

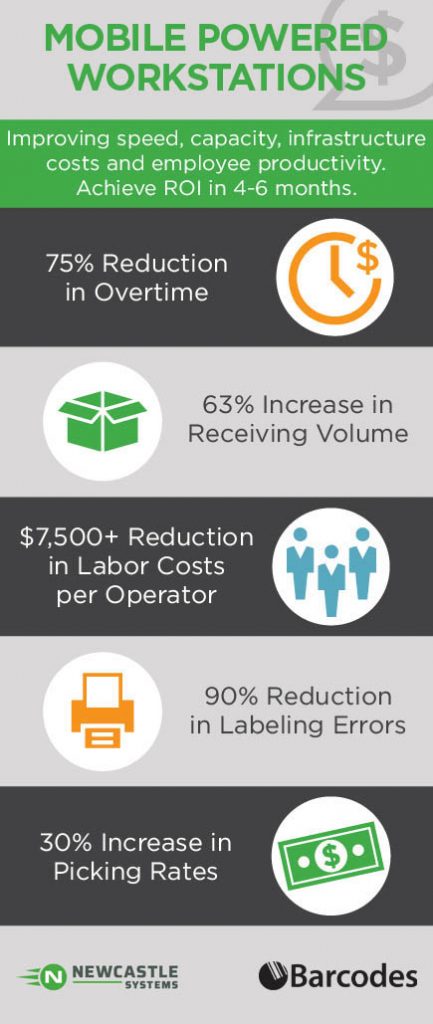

Newcastle Systems Mobile Powered Workstations