The Importance of Enhanced Security and Encryption Protocols for Wireless Hardware

In the storefront, at the office, throughout the warehouse, and on the road, wireless technology is a critical tool for conducting and improving business. Yet, despite its ubiquitous presence in business, we still read, almost daily, about hackers breaking into large network databases—heightening concerns about identity theft and credit card fraud. Security risks associated with wireless networks have forced businesses to comply with new, more stringent regulations for network security and data encryption. This document outlines the risks your wireless network faces and summarizes current state-of-the-art wireless hardware security systems. It also highlights critical factors to consider when selecting hardware partners to protect your future investment in wireless technology.

In the storefront, at the office, throughout the warehouse, and on the road, wireless technology is a critical tool for conducting and improving business. Yet, despite its ubiquitous presence in business, we still read, almost daily, about hackers breaking into large network databases—heightening concerns about identity theft and credit card fraud. Security risks associated with wireless networks have forced businesses to comply with new, more stringent regulations for network security and data encryption. This document outlines the risks your wireless network faces and summarizes current state-of-the-art wireless hardware security systems. It also highlights critical factors to consider when selecting hardware partners to protect your future investment in wireless technology.

The Business Case for Wireless

The use of 802.11 wireless devices has been a driving force in the advance of worker efficiency. It has also brought higher levels of service to retail and commercial customers alike. The unassailable benefits of wireless devices are driving the growth of 802.11 technology. According to the Wi-Fi Alliance, chipsets sold on an annual basis to support wireless technology will grow to one billion units by 2012 (Ref. ABI Research). Clearly, companies that ignore the value of wireless technology will be left behind as their competitors benefit from its many advantages. However, the use of wireless technology is not without risks, and astute companies will take measures to mitigate these risks before wholly embracing wireless devices.

Identifying Compound Interest in Your Field Service Workflow

How to attain best-in-class profitability by optimizing seemingly minor tasks

When asked what he thought the most powerful force in the universe was, Albert Einstein once replied, “Compound interest!†This post will demonstrate how compounding even small improvements in workers’ routines translates into huge profits. A field service workforce can attain best-in-class profitability by seeking out and optimizing seemingly minor tasks throughout a field worker’s day that are repeated over and over again, compounding not only throughout that worker’s day, but across all the workers in the organization. The optimization of those repeated tasks will lead to gains in field worker utilization and first time fix rate, which continue to be the key indicators of how well a service organization is running.

According to a recent Aberdeen report, best-in-class service organizations are achieving 74% field worker utilization as opposed to 60% for average companies and only 48% utilization for the poorest performing companies. In addition, best-in-class companies also lead in first visit fix rates of 90% versus only 71% for average companies.

A Guide to Smart Printing

Understanding the Capabilities, Use Cases and Advantages of Smart Printers

Understanding the Capabilities, Use Cases and Advantages of Smart Printers

Businesses are continually looking for ways to work smarter. Printing operations provide an excellent – and often overlooked – opportunity. One growing trend among companies with bar code printing operations is to leverage the capabilities of “smart†printers, which are printers that integrate the power of a personal computer. Smart printers enable businesses to change the way their printing operations are structured, to streamline and improve processes in ways that reduce operating costs while improving reliability.

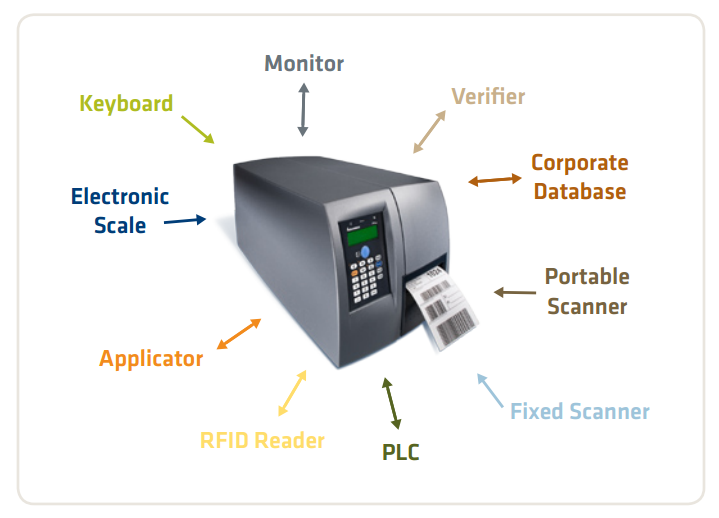

Smart printing takes advantage of the memory and processing power available in advanced printers to run printing operations independently, without a PC or network connection to another host computer. Smart printers can run software applications and can function as PLCs to control other devices, including scales, scanners and label applicators. By using the computing power that’s in the printer, organizations can reduce their IT hardware, networking and support requirements, lower the total cost of printing operations, and create work processes that improve productivity and reduce opportunities for errors.

Five Things to Consider When Using Tablet Computers in Forklift Applications

Why Tablets and Purpose Built Forklift-Mounted Computers Are Not Interchangeable

Tablet computing is one of the fastest-growing categories of consumer electronics and enterprise IT alike. The buzz is leading many businesses to explore new uses for tablet computers, and some are finding their way into evaluation trials on forklifts and other vehicle applications in the distribution center. With their large screens and available Windows operating systems, tablets can seem quite similar to the forklift-mounted computers that are widely used today. They can also be taken off the forklift and used on the floor, which some organizations find intriguing.

However, tablets should not be considered drop-in replacements for purpose-built forklift mounted terminals because there are several major differences between the product categories. If you are considering using tablet computers on forklifts, it is important to know these differences and how they may impact operations. Careful evaluation will highlight compromises in integration and everyday use.

This post reviews some of the important differences between tablets and purpose-built computers for forklifts, and presents the five key issues that must be considered when assessing tablet computers for forklift operators:

- Is the design and mounting appropriate for a warehouse or distribution center environment?

- How will the tablet be powered from the forklift?

- Is the tablet compatible with data collection equipment(scanners, printers, RFID), legacy warehouse management system (WMS), fleet management solutions and other critical enterprise systems?

- How will tablets impact user processes and productivity?

- How much will tablets really cost?

Future Proofing Your Mobile Computers

How the Features You Select Now Can Protect & Extend Your Investment Years into the Future

How the Features You Select Now Can Protect & Extend Your Investment Years into the Future

Rugged mobile computers deployed to warehouses, DCs and other transportation and distribution environments often aren’t used as long as expected, and as result cost the organization more than expected. Companies typically replace their DC computers after about 3 1/2 years, which is approximately seven months sooner than planned at the start of the deployment, according to a study. Rugged devices can actually last even longer, but are retired prematurely because the processors, software, communications data capture capabilities contained within the rugged housing are considered inefficient or obsolete.

Extending service life increases the value of mobile computers. When life cycles go down, so does the return on investment, and the total cost of ownership (TCO) goes up. The table below illustrates how changes in the replacement cycle impact the TCO for mobile computing deployments. It reflects how much the purchase price of a $3,000 rugged computer used in warehousing and distribution contributes to the annual and monthly TCO. Note that replacing mobile computers after 31/2 years instead of four (which is about the average intended life cycle) increases the annual TCO allocation by $107, or 14.2 percent.

Smart Printers. Smart Investment.

People generally relate to industrial printers as they do to their desktop printers. It’s a “dumb†device that prints whatever a computer sends it. As long as it does that well and keeps working, people really don’t think too much about it.

Bar code printers have generally fallen into the same “dumb†and reliable category, but are also rugged and fast at producing labels.

However, there is a different type of industrial-strength printer that’s in a class by itself. It has the same characteristics as other bar code printers—rugged, fast, and reliable—but these printers are “smart.†Smart printers have built-in intelligence that enables them to perform a wide variety of operations that normal printers cannot.

First, smart printers do not require a computer to be able to produce labels. The immediate benefits are you save the cost of a computer dedicated to controlling the printer and you save space by reducing the number of devices needed to perform operations. Smart printers’ intelligence also allows them to actually run processes and devices. Smart printers can act as programmable logic controllers (PLC) to run other devices in production applications.

Smart printers are not new; they have been manufactured for over a decade. The latest generation delivers even more capability than before, adding advanced bar code printing capabilities, errorproofing, the ability to print directly from ERP systems via XML data, and RFID labeling and data management capabilities.

The Common Sense Case: Why Thermal Trumps Laser for Label Printing

“When you’re finished changing, you’re finished,†said Benjamin Franklin, a printer and purveyor of common sense. This paper, makes the common-sense case for using thermal printers in label applications. In fact, the advantages of thermal over laser are so compelling that the only reason to continue using laser printers for labeling must be habit. Before enumerating the advantages of thermal printing technology over laser, it will be useful to consider the use of laser printers for labeling.

Laser Printing Labeling: History and Concerns

Laser printers have long been used in label printing applications, chiefly because a base of laser printers are usually already installed—primarily for forms, letters, and other narrative communications and documentation. Their multi-function capability made it relatively easy to adopt the laser printer hardware for printing labels. Since adoption was easy, a thorough examination of the technology’s appropriateness was rarely undertaken. Parameters such as operating costs, total cost of ownership, materials and energy usage, ergonomics, and other relevant factors were simply not considered in the label printing context.

After laser label printing applications became the de facto standard, users began to see the shortcomings of using laser printers for this function. While many are now demanding better label printing solutions, they are challenged by inertia in the form of a huge installed base of laser printers.

How e-Citation Systems Increase Productivity & Revenues While Improving Officer Safety

Electronic citation (e-Citation) systems represent one of the most succcessful uses of mobile and wireless technology in public safety operations. Electronic citation systems have earned high user satisfaction ratings from state highway patrol agencies, police departments, parking authorities and campus security organizations across the country because of their well-proven ability to save time for officers, improve safety while issuing tickets, reduce errors and illegible tickets, and improve collection rates.

The only significant obstacles to more widespread use of electronic citation systems are insufficient awareness, understanding and budgets. This white paper will provide the background information needed to pursue an e-Citation initiative, plus benefit data and tips to help win funding for it.

e-Citations in Action

The Snohomish County (WA) Sheriff’s Office experience with electronic citation systems is typical. Deputies in the traffic unit each used to write about 12 to 15 paper citations a day. Each citation took four to five minutes to write, and a similar amount of time back at headquarters to enter into the computer system. With 20 traffic deputies working on a typical day, the sheriff’s office collectively spent between 43 and 47.5 hours daily writing and entering citations.

Snohomish County switched to creating citations on handheld computers, which produce a copy for the offender on a vehicle mounted printer and automatically download the citation information to the headquarters computer system without manual data entry. Productivity – and citation revenue – have since soared.

The Next Generation Warehouse : Long Range Scanning and the Emergence of 2D Barcodes

Introduction

Today’s warehouses are rapidly evolving as they seek to keep up with a variety of new requirements and advancements in technology. Processes traditionally using 1-dimensional bar codes are becoming more accurate, more efficient, and more robust through the transition to 2D symbologies. Offering superior data storage capability yet compact in size, these 2D symbols are ideal for cradle-to-grave tracking of products and serialization. As imaging technology progresses, businesses are poised to take advantage of the benefits of implementing 2D while continuing to accommodate the long range scanning requirements typical in the warehouse environment.

Driving this transition is the growing need to track individual parts from assembly to shipment and beyond for information and traceability purposes, largely imposed by company-specific or legislative requirements. A 2D bar code can accommodate significantly more information than its 1d counterpart, and in a fraction of the space, making such traceability possible.

Historically, laser scanners have been the preferred technology in warehousing because of their speed, accuracy, and ability to read at long range. however, as 2D bar codes become more common and imaging technology matures, manufacturers are now discovering what imagers have to offer in terms of flexibility, traceability, and legislative standards compliance.

The Power of Mobile Printing in the Warehouse and Beyond

In today’s precarious economic environment, global enterprises are experiencing a dual pinch: one, difficult times have cut operating budgets significantly, and rehiring to support growth after the contraction remains difficult; secondly, as investments in new equipment and systems have been delayed or denied, the optimization of warehouse and supply chain processes has become a critical factor in balancing costs, labor, and assets. What’s more, this optimization must occur while maximizing productivity and improving responsiveness to customer demands.

In today’s precarious economic environment, global enterprises are experiencing a dual pinch: one, difficult times have cut operating budgets significantly, and rehiring to support growth after the contraction remains difficult; secondly, as investments in new equipment and systems have been delayed or denied, the optimization of warehouse and supply chain processes has become a critical factor in balancing costs, labor, and assets. What’s more, this optimization must occur while maximizing productivity and improving responsiveness to customer demands.

With the growing emphasis on cost cutting, companies need to find new and better ways to enhance efficiencies and ensure accuracy across their supply chains and distribution networks. One strategy that is still effective in helping achieve this goal is the implementation of greater mobility into warehousing and distribution functions through devices such as mobile printers.

According to a recent study, mobile devices and software commonly improve workforce production by 20 percent or more. This translates into lower labor costs, lower operating costs, and faster payback on investment. Such gains are not hard to envision. By minimizing the time needed to print labels and apply them to materials, work in process, finished goods, pallets, boxes, and so forth, mobile printers help drive down labor costs while improving performance on the warehouse and DC floors.