Real ROI with RFID Asset Tracking: Watch Video

In today’s asset-heavy industries, real-time visibility has become essential for efficiency and resilience. Levata, parent company to Barcodes Inc., recently partnered with RFID specialists from HID Global and ARK Business Systems to host a webinar showcasing how RFID asset tracking reshapes the way organizations manage equipment, inventory, and valuable resources.

The discussion explored deployment strategies, technology choices, and customer success stories, giving attendees a clear picture of how RFID delivers operational control and measurable returns. If you didn’t catch it live, the on-demand recording is available.

The Three Building Blocks of RFID Success

The speakers highlighted that achieving success with RFID requires alignment of three critical elements:

1. Devices and Tags

From rugged tags that endure extreme environments to highly sensitive ones for delicate applications, HID alone offers thousands of RFID tag types. Hardware choice is equally important—mobile readers may be best for field use, while fixed readers are ideal for continuous monitoring.

2. Software Intelligence

Effective RFID systems go beyond capturing tag data. The software layer transforms raw reads into actionable insight—tracking locations, supporting audits, scheduling maintenance, and even managing financial depreciation across the asset lifecycle.

3. Services & Expertise

RFID isn’t a simple plug-and-play solution. Partnering with experts like Levata and Barcodes Inc. ensures smooth integration—covering device selection, configuration, staff training, and long-term support.

Why RFID Outperforms Manual Tracking

Traditional spreadsheets and manual audits are slow, inaccurate, and resource intensive. RFID changes the game by:

- Reducing audits from hours to minutes

- Assigning each asset a unique digital ID

- Automating data collection with real-time updates

- Creating complete usage and history logs

- Supporting pre- and post-event assessments

One customer example involved wildfire response efforts, where RFID enabled instant tracking of hundreds of thousands of assets—something spreadsheets could never achieve.

Greater Accuracy, Speed, and Ease of Use

With advancements in tag design and reader sensitivity, today’s RFID systems achieve read accuracies in the high 90s. But performance is not just about precision; it’s also about speed and usability. Field workers, finance teams, and administrators all benefit from systems that are fast, consistent, and simple to operate.

Customer Success in Action

The webinar spotlighted diverse real-world applications:

- Enterprise Tracking: A company previously dedicating nine months of labor to manual audits cut the time by 50% after adopting RFID, allowing staff to focus on strategic work.

- Scientific Research: Dinosaur fossils were tagged with RFID to capture excavation details, photos, and species data—simplifying cataloging and enabling cross-site comparisons.

- Higher Education: A university reduced classroom audit times from 25 minutes to 5 using RFID handheld readers, with training that took less than 10 minutes per staff member.

Why the Right Partner is Critical

Technology alone doesn’t guarantee success—expert guidance ensures ROI. Barcodes Inc., a Levata company, helps organizations:

- Define objectives and success criteria

- Select the right mix of tags, devices, and software

- Test and fine-tune technology for optimal performance

- Train teams for sustained results

With the right approach, many organizations see payback in as little as six months.

Take the Next Step

Whether you’re seeking better control in day-to-day operations or need rapid visibility during emergencies, RFID asset tracking provides the visibility you need. Barcodes Inc. has the expertise to help you implement a strategy that delivers long-term value.

>> Watch the free webinar recording

>> Contact Levata to start building your business case and to receive an ROI analysis.

Meeting RFID Labeling Mandates: 5 Critical Factors to Consider When Selecting a Printer

If you’ve recently received a mandate from a customer or partner requiring RFID tagging on product shipments, you’re not alone. Many major retailers are increasingly pushing their suppliers to adopt RFID labeling standards—often through the ARC program—to improve inventory accuracy and supply chain visibility. What is the ARC program? The ARC program, standardizes RFID tagging requirements across industries such as retail, aviation, and manufacturing. Failing to comply with ARC-certified tagging requirements can lead to costly chargebacks, rejected shipments, and a breakdown in supply chain trust—putting supplier relationships and business continuity at risk.

Using the right RFID tag is only part of the equation. Selecting the right RFID printer and software is just as critical. The printer not only applies data to the label—it encodes the RFID inlay with a digital identity.

You might ask, how do I select the right RFID printer? Here are five essential considerations to help you choose the right RFID printer for a successful RFID labeling protocol.

1. RFID Compatibility: UHF vs. HF

RFID tags typically fall into two categories: UHF (Ultra-High Frequency) and HF (High Frequency). Depending on the specifications or ARC certification requirements, your printer must support the correct standard.

- UHF: Offers longer read ranges (up to 10 feet), making it suitable for carton-level tagging, dock door scans, and high-speed conveyor systems.

- HF: Best for short-range reads (up to 3 feet), such as item-level tracking in retail or healthcare.

Pro Tip: Make sure the printer you select is compatible with the frequency range you need—and ideally, one that supports both HF and UHF if you serve multiple markets.

2. Flawless Encoding Capabilities

Encoding is not just about writing data to a tag—it’s about writing it accurately and reliably. Look for RFID printers that provide:

- On-screen menus for antenna position optimization

- The ability to store presets and settings, so you can print and encode multiple tag types from a single device

Pro Tip: Flawless encoding reduces the risk of errors that lead to unreadable tags or failed scans during transit or at receiving docks.

3. Speed and Label Precision

You may be required to print small-format RFID labels for individual items. The printer you select needs to be able to handle small label sizes with high accuracy—without slowing down your production line.

Pro Tip: Choose a model that balances speed with precision, ensuring it can keep up with your label volume while maintaining clarity in both print and encoded data.

4. Duty Cycle and Media Capacity

If you’re printing hundreds or thousands of RFID tags daily, a desktop model may not suffice. Industrial-grade printers with high-duty cycles are designed to handle continuous use and offer:

- Larger ribbon and label roll capacities

- Fewer supply changeovers

- Reduced downtime and greater efficiency

Pro Tip: A printer like the SATO CL4NX Plus RFID is specifically designed for heavy-duty environments with high-volume output.

5. Cloud-Based Printing & Data Management

Modern RFID printers should do more than print. Look for solutions that offer cloud-based software integration to:

- Allow multi-site printing from a centralized system

- Maintain a record of encoded EPCs

- Prevent duplication of serialized data

- Send real-time alerts for print errors or anomalies

Pro Tip: This centralized control is especially important for suppliers with distributed operations or those scaling RFID labeling across multiple facilities.

SATO’s RFID Printing Solutions: Purpose-Built for Performance and Compliance

SATO is a leader in RFID tag and label printing, offering advanced solutions that meet the growing demands of supply chain traceability, compliance, and item-level visibility. Let’s review two popular SATO RFID printers engineered to ensure reliable encoding, high-speed performance, and compatibility with industry standards.

SATO CL4NX Plus RFID – Industrial Strength, Maximum Flexibility

Designed for high-volume, high-duty cycle environments, the CL4NX Plus RFID printer delivers robust performance for demanding operations:

- Supports HF and NFC Standards: ISO 15693 compatibility for short-range applications

- UHF Encoding: EPC Class 1, 0+, and Gen 2 support for long-range tracking

- Dual Antenna Design: Enables bottom and top encoding for enhanced tag compatibility

- Printhead-Antenna Integration: Features a second antenna for short-pitch and top-side encoding, essential for printing on metal tags—ideal for asset tracking in industrial, IT, and healthcare applications where traditional tags fall short

SATO CT4-LX RFID – Compact Powerhouse for Desktop Use

For businesses needing desktop-size versatility without sacrificing RFID capability, the CT4-LX RFID printer is a compact yet powerful solution:

- HF and UHF Support: Complies with ISO/IEC 15693, ISO/IEC 14443 (HF), and ISO/IEC 18000-6C (UHF Gen 2) standards

- Dual Antenna System: Combines a front fixed-position antenna with a standard encoding antenna to support diverse media types and encoding positions

- User-Friendly Interface: Ideal for decentralized or smaller-scale operations needing consistent RFID tag output without industrial footprint

Whether you’re printing thousands of pallet labels a day or managing RFID tagging at the item level, SATO provides scalable, standards-compliant solutions that meet today’s RFID labeling requirements and future-proof your supply chain operations.

Final Thoughts

Compliance with an RFID labeling mandate doesn’t have to be overwhelming. By selecting the right RFID printer—one that’s compatible with your tags, delivers precise and fast encoding, and integrates with cloud-based management software—you can streamline compliance and unlock additional value in your supply chain.

Contact Barcodes Inc. today to learn more about robust RFID printers like the SATO CL4NX Plus RFID and CT4-LX RFID that will help you build an efficient RFID tagging program.

Case Study: Premier Guard Transforms Inventory Management with RFID Solutions

Premium Guard Inc. (PGI) is a leading global manufacturer of aftermarket automotive products, including filters and wiper blades. Since its founding in 1996, PGI has focused on designing, manufacturing, and distributing high-quality products for automotive, diesel, power-sports, and specialty filter markets. Offering complete turnkey private label programs to retailers, buying groups, and independent warehouse distributors, PGI faced operational challenges in supply chain accuracy and efficiency. To address these challenges, PGI partnered with Levata, parent company to Barcode’s Inc., to implement a cutting-edge RFID-based inventory tracking and shipment accuracy system.

Business Challenge

Premium Guard’s supply chain is complex, with a high expectation of accuracy from auto parts retailers, distributors and aftermarket businesses. Ensuring the right part and the right quantity shipped to the correct destination on time are critical, as delays or errors can result in customer dissatisfaction and costly chargebacks.

“We ship high volumes weekly to multiple automotive aftermarket retailers, often filling entire truckloads with each order. Manually double-checking and auditing every pallet is overwhelming, yet missing products can lead to costly chargeback fees. After discovering the capabilities of RFID technology, we partnered with Levata to implement a smarter solution—enhancing visibility, improving accuracy, and elevating customer service,” said Jim Allosso, Director of Warehouse Operations at Premium Guard.

Key challenges included:

- Mis-shipments leading to chargebacks and return freight payments.

- Inventory discrepancies impacting operational efficiency.

- Lack of real-time visibility in warehouse operations.

Recognizing the need for improvement, PGI’s leadership committed to a solution that would ensure customers received exactly what they ordered, leading to the adoption of an RFID-based workflow.

The Solution

Premium Guard needed a partner that could provide customized, cutting-edge technology that addressed key challenges in supply chain management. Levata’s RFID systems, such as RFID tunnels, dock doors, and mobile readers, offer accurate inventory tracking and real-time visibility, which are critical for reducing mis-shipments, lowering chargeback costs, and improving operational efficiency.

With Levata, PGI has launched a phased RFID implementation. PGI sought to enhance customer service through enhanced inventory management operations for its largest customer, a leading national retailer of automotive parts and accessories. The solution involved multiple components tailored to PGI’s unique operational needs. PGI committed to an extensive relabeling project to fully integrate RFID technology effectively, involving the relabeling of over 600,000 boxes. Additionally, ten vendors began incorporating RFID labels into their shipments, further streamlining PGI’s receiving process.

RFID Infrastructure & Technology

A custom-built RFID Tunnel (SLS T-Series) was integrated with PGI’s ERP system to count pallet content accurately and validating that shipments include the right materials. RFID Dock Doors (SLS D-Series) were installed to ensure shipments were loaded onto the correct trucks, while RFID Mobile Readers (SLS M-Series) supported cycle counting of pallets in the warehouse. To provide real-time tracking and data insights, PGI leveraged the SLS View RFID cloud software.

To further streamline operations, PGI deployed powered mobile carts powered mobile carts equipped with RFID label printers and AirTrack Performance label supplies, allowing for efficient RFID labeling right on the warehouse floor. Additionally, handheld mobile RFID readers and mobile computers enabled mobile scanning and verification, creating seamless interaction with the RFID system powered by cloud-based software.

“From day one, we’ve worked with a dedicated Levata team deeply involved in every phase of our project,” said Jim. “Their solution architects designed a highly customized system, field experts collaborated directly with our floor teams, and specialists guided our manufacturing partners through new processes. No matter the challenge, Levata has been there with reliable support we can count on.”

Benefits and Results

Premium Guard has already seen significant improvements with the new system:

- Highly accurate scanning, with both the RFID tunnel and dock doors performing exceptionally well.

- Enhanced insights from customized reporting.

- Stronger supply chain visibility, reducing inefficiencies and ensuring greater accuracy in shipments.

With the success of the initial phase, PGI is planning to expand their RFID implementation. It will roll out the new process for other large customers, resulting in a dedicated dock door for each customer for smooth, efficient order verification. The expansion will include more vendor participation, too. Having vendors ship parts with RFID labels enables seamless integration with the warehouse’s RFID system, improving inventory accuracy, accelerating processing times, and enhancing overall supply chain efficiency.

By leveraging Levata’s advanced RFID solutions, PGI has significantly improved its supply chain efficiency, reduced operational costs, and strengthened its reputation as a reliable partner in the automotive aftermarket industry. To learn more about our RFID technology solutions, contact us today!

Comparing RFID vs. Barcode Technology: Which is Best for Your Business?

In today’s fast-paced business environment, efficient inventory tracking and asset management are critical for success. Two of the most commonly used technologies for these tasks are RFID (Radio Frequency Identification) and barcode scanning. Both play essential roles in supply chain operations, retail, healthcare, and manufacturing, but they differ in functionality, cost, and efficiency. This article compares RFID vs. barcode technology to help you determine which is the best fit for your business.

Understanding Barcode Technology

Barcode technology has been a staple in inventory management for decades. It uses optical scanning to read printed barcodes, which store data in a linear or 2D format. Each barcode represents a unique identifier that corresponds to product or inventory information stored in a database.

Advantages of Barcode Technology:

- Cost-Effective – Barcodes are inexpensive to produce and print.

- Simplicity – Easy to integrate with existing inventory systems.

- Accuracy – Minimizes manual errors when scanned properly.

- Wide Adoption – Used globally across multiple industries.

Limitations of Barcode Technology:

- Requires Line of Sight – A scanner must be directly pointed at the barcode.

- Limited Data Storage – Traditional barcodes store minimal information.

- Manual Scanning – Each item must be scanned individually, which can be time-consuming.

View best-selling barcode scanners >>>

Understanding RFID Technology

RFID technology uses radio waves to transmit data between a tag (attached to an item) and a reader. Unlike barcodes, RFID tags do not require a direct line of sight and can be scanned from a distance. This technology is increasingly being adopted for real-time asset tracking, automated inventory counting, and supply chain visibility.

Advantages of RFID Technology:

- Faster Data Capture – Can scan multiple tags simultaneously.

- No Line of Sight Required – Readers detect tags even if they are hidden inside packaging.

- Greater Data Storage – RFID tags can store more detailed information.

- Improved Security – Can include encryption and authentication features.

Limitations of RFID Technology:

- Higher Initial Cost – RFID tags and readers are more expensive than barcodes.

- Interference Issues – Metal and liquids can disrupt signals.

- Integration Challenges – Requires specialized software and hardware.

| Feature | Barcode | RFID |

| Cost | Low | Higher initial investment |

| Scanning Speed | One at a time | Multiple at once |

| Line of Sight | Required | Not required |

| Data Storage | Limited | More storage capacity |

| Durability | Can fade or tear | More resistant to damage |

| Interference | No issues | Can be affected by materials like metal and liquids |

View best-selling RFID readers >>>

Which Technology is Best for Your Business?

The choice between RFID and barcode technology depends on several factors, including budget, operational needs, and industry requirements.

- Retail & Small Businesses – Barcodes are typically the better choice due to their low cost and ease of use.

- Warehousing & Logistics – RFID can streamline large-scale inventory tracking and reduce human labor.

- Healthcare & Pharmaceuticals – RFID ensures better tracking of medical supplies and patient records.

- Manufacturing & Automotive – RFID enables real-time asset tracking and quality control.

Conclusion

Both RFID and barcode technology have their unique strengths and limitations. Barcodes remain a cost-effective and widely used solution, while RFID provides faster, more efficient tracking with greater automation potential. Businesses looking for low-cost inventory control may prefer barcodes, whereas companies requiring high-speed, real-time tracking should consider RFID.

Choosing the right AIDC solution depends on your specific business goals, operational scale, and budget. Let Barcodes, Inc. help evaluate your needs carefully, so that you implement the best tracking system to enhance efficiency and accuracy in your operations.

The Value of RFID in Inventory Management & Supply Chain Visibility

Radio Frequency Identification (RFID) is revolutionizing inventory management and supply chain visibility. While barcodes have been the dominant tool for item identification for decades, RFID offers a powerful alternative with advantages like real-time tracking, non-line-of-sight reading, and faster automation. Although RFID implementation requires more planning and investment than barcoding, it can provide significant efficiency gains for businesses seeking to streamline operations and reduce errors.

Why RFID is Worth Considering

To determine if RFID is the right fit for your business, it’s important to evaluate your needs and operational challenges. Unlike barcodes, RFID does not require line-of-sight to read tags, which makes it ideal for tracking items moving through conveyor systems or stored in hard-to-see locations. The technology also supports varied read ranges, from a few inches to over 10 feet, depending on the tag and reader setup. RFID can be particularly effective when items are traveling at high speeds or are fixed at certain checkpoints.

However, environmental factors must be considered. Items containing metal or liquids can interfere with RFID signals, impacting system performance. Similarly, the choice of fixed or mobile readers depends on whether you need automated scanning at warehouse entry points or manual inventory checks on the move.

Types of RFID Technologies

RFID operates in three main frequency ranges. Low Frequency (LF) systems work well for close-contact applications like ID badges or access control, but their range is limited to a couple of inches. High Frequency (HF) systems can read tags up to 3 feet away, making them ideal for small item tracking and applications like healthcare equipment management.

For supply chain and inventory purposes, Ultra High Frequency (UHF) is the most widely adopted RFID solution. UHF systems offer extended read ranges of up to 10 feet, making them highly effective for item-level and container-level tracking. UHF’s affordability and flexibility have made it a popular choice for businesses looking to manage large volumes of inventory efficiently.

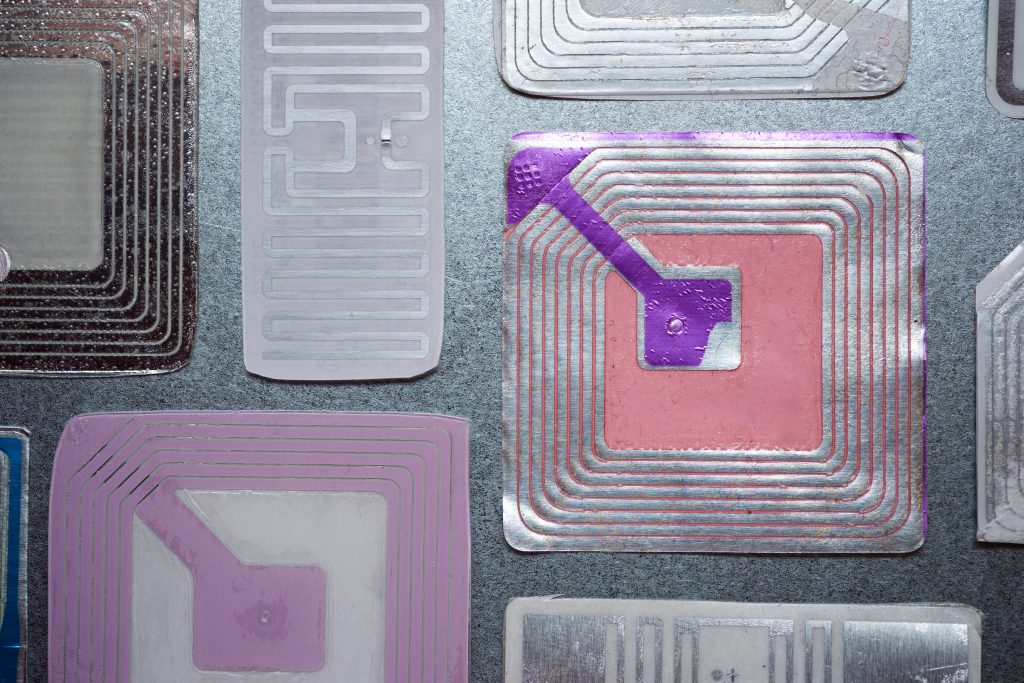

RFID tags are also classified as active or passive. Active RFID tags have their own battery power, enabling long-range and high-speed scanning, but they are costly and bulky. Passive tags, on the other hand, rely on the reader’s signal for power, making them thinner, more affordable, and ideal for product-level tracking in inventory systems.

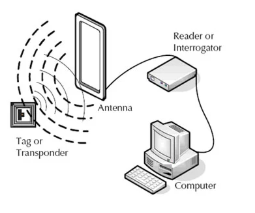

How RFID Works

A typical RFID system includes four key components: tags, antennas, readers, and host software. When a passive RFID tag enters the signal field of an antenna, the tag receives power from the reader. It then “backscatters” its stored data, which is captured by the antenna and processed by the host software. Unlike barcodes, RFID tags can be read even if they are not in direct view or perfectly oriented, enabling faster and more efficient inventory tracking.

The host software uses the captured data for applications such as asset tracking, inventory control, or logistics management. For example, fixed RFID readers can monitor inventory as it passes through warehouse doors, while mobile readers allow employees to conduct manual counts while on the move. Desktop RFID readers offer a plug-and-play option for situations that require reading tags next to a PC, such as retail checkouts or quality control stations.

Challenges and Limitations

While RFID is highly effective, it is not without limitations. Environmental factors such as metals and liquids can interfere with signals, reducing accuracy. Dense collections of items may also pose challenges, as tags in the center may not receive enough signal power to activate. These factors require extensive testing and system design to achieve optimal results.

Additionally, RFID systems involve higher upfront costs compared to barcode solutions. However, businesses that plan carefully and implement RFID effectively often achieve significant long-term savings through reduced errors, improved accuracy, and labor efficiency.

Components of an RFID System

An RFID system begins with the selection of the right tags, which are designed with a combination of chipsets and antennas to store and transmit data. The choice of tags depends on the environment, product type, and read requirements. For high-volume applications, RFID printers simplify the process by encoding tags and printing barcodes as a backup, ensuring data accessibility even if the RFID tag is damaged.

The RFID readers themselves come in various forms. Fixed readers are ideal for automated scanning at checkpoints, such as warehouse docks or conveyor lines. Mobile readers, which resemble handheld computers, are versatile tools for conducting inventory counts and asset tracking across facilities. Desktop readers, though limited in range, offer quick and easy data capture for localized applications.

Finally, middleware software ties the system together. Unlike barcode scanners, RFID readers do not output basic text data directly. Instead, middleware processes the RFID data and integrates it with inventory management or enterprise software. Systems supporting Low Level Reader Protocol (LLRP) ensure compatibility with most RFID readers.

The Benefits of RFID in Supply Chain Management

The greatest value of RFID lies in its ability to enhance efficiency, accuracy, and automation. It enables businesses to track inventory in real time without requiring manual scanning. By reading multiple tags simultaneously, RFID reduces the time and labor involved in inventory checks. Its non-line-of-sight capability allows for greater flexibility, especially in environments where items are stacked, moving, or difficult to access.

Conclusion

RFID technology is transforming the way businesses manage inventory and supply chains by offering faster, more accurate, and automated tracking solutions. While the technology presents challenges, such as signal interference and higher initial costs, the benefits far outweigh these limitations when implemented correctly.

For businesses exploring RFID, it is best to start with a small-scale pilot project, test its feasibility, and gradually scale up. With careful planning and the right resources, RFID can provide unparalleled visibility and efficiency in your inventory management processes, giving you a significant edge in a competitive market.

How Connected Packaging Powers the Circular Supply Chain

Connected packaging is revolutionizing supply chains, boosting efficiency, and driving sustainability. John Dwyer, Vice President of Digital Innovation at Smurfit WestRock, highlighted the transformative potential of Born-Digital packaging during a guest session hosted by Levata. Barcodes, Inc. is a Levata company.

By combining cutting-edge technologies like traceability, automation, and circular economy principles, Smurfit WestRock is redefining the role of packaging in modern business. Below is an overview of Dwyer’s insights and the impact of Born-Digital packaging on sustainability and supply chain efficiency.

Transforming Supply Chains with Connected Packaging

Traditional supply chains often face inefficiencies, including waste from overstocking. The pandemic exposed these vulnerabilities, emphasizing the need for smarter, connected solutions.

Smurfit WestRock’s Born-Digital packaging integrates advanced technologies like RFID, Bluetooth Low Energy (BLE), NFC, and serialized QR codes into packaging, creating digital identities for products. These innovations enable real-time tracking, improve inventory visibility, reduce waste, and optimize delivery timelines.

For instance, Smurfit WestRock collaborated with a quick-service restaurant chain to track fresh beef throughout its supply chain. By incorporating RFID technology into refrigerated packaging, the company ensured precise, scalable solutions for transitioning from frozen to fresh beef—an essential step for maintaining quality and meeting demand.

Driving Recycling and Sustainability

Sustainability is at the core of Smurfit WestRock’s operations. The company operates 32 recovery facilities in North America, collecting two-thirds of Walmart’s packaging waste and transforming it into new materials. This closed-loop system supports retailers’ ESG goals while reducing waste.

A standout example is Smurfit WestRock’s leadership in the pizza box market, producing approximately 3 billion boxes annually, covering 55% of the U.S. market. Domino’s has introduced QR codes on its boxes to educate customers about local recycling guidelines. Research conducted by Smurfit WestRock confirms that pizza boxes are recyclable, even with food residue, further reducing environmental impact.

Key Trends Shaping Born-Digital Packaging

Several key trends are driving the adoption of connected packaging:

- Real-Time Data Demand: Businesses require instant access to data for better decision-making, particularly in retail and logistics. Connected packaging improves inventory accuracy and supply chain visibility.

- Enhanced Connectivity: Innovations like Wi-Fi 6E and 5G ensure seamless data transfer in harsh environments.

- Circular Economy Integration: Businesses are prioritizing recyclable materials and digital traceability to minimize environmental footprints and meet regulatory standards.

Smurfit WestRock is leading the charge with advanced solutions like light-sensitive sensors that detect unauthorized package openings, enhancing security and trust. By creating scalable, end-to-end systems in partnership with companies like Barcodes, Inc. and SLS, the company ensures seamless integration of sensors, readers, and gateways to address complex supply chain challenges.

Maximizing ROI with Smart Packaging

Connected packaging offers businesses significant returns on investment, often within 12 months. Automating processes like cycle counting allows organizations to redeploy labor to higher-value tasks, reducing costs and improving efficiency.

For instance, smart packaging helps retailers avoid costly penalties for incomplete or late shipments by providing electronic proof of delivery.

A Vision for a Sustainable Future

John Dwyer concluded his presentation by reaffirming Smurfit WestRock’s dedication to the circular economy. Approximately 30% of old corrugated containers in the U.S. are recycled into new packaging, showcasing the company’s commitment to sustainability. As regulations like FSMA and EPR evolve, Smurfit WestRock’s ability to track and recycle packaging will remain a vital tool for achieving compliance and advancing sustainability.

Discover the Future of Packaging

By combining innovation, sustainability, and strategic partnerships, Smurfit WestRock is revolutionizing packaging and creating a smarter, more connected supply chain. Learn how your business can leverage connected technologies, recycling innovations, and sustainable practices to transform your operations and meet evolving market demands.

Contact us today to explore the power of Born-Digital packaging in driving a sustainable, circular economy.

From Challenges to Triumph: Yamaha G3 Boats’ RFID Journey

When Yamaha G3 Boats faced challenges with visibility, efficiency, and tracking in their production process, they turned to Barcodes, Inc to implement an RFID solution. This strategic move aimed to increase production capacity and streamline operations, ultimately paving the way for significant growth and improved productivity. Their success was recognized with the ‘Best Manufacturing Implementation of RFID’ award at the 2024 RFID Journal Live, demonstrating the impact of advanced technology in overcoming operational bottlenecks.

About Yamaha

Yamaha G3 Boats is renowned for producing high-quality aluminum fishing boats and recreational pontoon boats. With a strong commitment to craftsmanship and innovation, they’ve earned a reputation for delivering durable and reliable vessels. Their product range caters to both avid anglers and recreational boaters, offering top-notch performance and comfort on the water. Yamaha G3 Boats is also known for their continuous improvement initiatives, consistently integrating advanced technologies to enhance both manufacturing processes and product offerings.

Barcodes, Inc Advantage

To tackle the challenges of visibility, efficiency, and tracking in their manufacturing process, Yamaha turned to Barcodes, Inc’s cutting-edge RFID systems, which delivered an ideal solution. By deploying RFID technology, Yamaha was able to:

- Enhance Visibility: Barcodes, Inc’s RFID technology provides real-time visibility into the production line. RFID tags attached to each boat and key components allow Yamaha to track their location and status at every stage of production. This real-time data enables the company to quickly identify and resolve issues, ensuring smoother production processes.

- Improve Efficiency: With comprehensive tracking capabilities, RFID technology optimizes workflow on the shop floor. Identifying bottlenecks and streamlining operations allows Yamaha to meet production schedules more accurately and efficiently. Additionally, automated data entry and ERP system integration further boost operational efficiency.

- Accurate Tracking: RFID tags enable precise tracking of each boat throughout the manufacturing process. This accuracy minimizes errors and improves resource allocation. Real-time tracking of every component and work order ensures production stays on schedule, leading to improved throughput.

Looking Ahead

Yamaha G3 Boats continues to expand its RFID capabilities with future phases planned. By partnering with Barcodes, Inc, Yamaha remains poised to meet market demands and maintain their competitive edge.

The success of Yamaha G3’s RFID implementation is a milestone for Barcodes, Inc, and we look forward to continuing this partnership to achieve even greater accomplishments. Congratulations to everyone involved in this project!

From Farm to Fork: Ensuring Food Safety with Effective Labeling

Food safety is a top priority for everyone involved in the food supply chain, from farmers and manufacturers to distributors, retailers, and ultimately, consumers. Contaminated food can cause serious illness, and preventing these outbreaks requires a multi-pronged approach. One critical element in this strategy is effective food safety labeling. The best food label printers are designed to meet the specific requirements of the food industry, offering advanced features that enhance food safety practices. Read further to learn the importance technology plays in ensuring accurate and efficient labeling practices.

Why Food Safety Labeling Matters

Food safety labeling plays a crucial role in safeguarding consumers from potential hazards. It allows for accurate tracking of food products throughout the supply chain, facilitating swift and targeted action in case of recalls or contamination concerns. Clear and consistent labeling also empowers consumers to make informed choices about the food they eat.

Here are some specific ways food safety labeling contributes to a safer food system:

- Traceability: Labels with essential information like batch numbers, expiration dates, and processing facilities enable tracing in the event of recalls.

- Allergen Awareness: Clear and accurate allergen labeling on food packaging allows consumers with allergies to make safe choices.

- Ingredient Transparency: Detailed ingredient lists on labels help customers with specific dietary needs or preferences make informed choices.

- Best-Before Dates: Best-before dates advise consumers when food maintains its optimal quality and safety.

- Instructions and Warnings: Labels can include instructions for proper handling, storage, and preparation of food.

Technology’s Role in Food Safety Labeling Accuracy and Efficiency

Label printer technology plays a vital role in ensuring the accuracy and efficiency of food safety. As North America’s leading provider of barcode and product labeling, mobile computing, and RFID solutions, Barcodes Inc. partners with the most trusted brands in the food service and grocery industry that offer unique food labeling features.

- Digital Printing Solutions: Advanced digital printing technologies facilitate on-demand printing of labels, allowing for real-time updates and increased flexibility. This reduces waste and ensures the most recent information is included on labels.

- Variable Data Printing: This technology allows for printing unique information like lot codes and expiration dates on each individual label, enhancing traceability and facilitating targeted recalls if needed.

- Label Management Software: Centralized software solutions streamline the creation, approval, and printing of food safety labels, fostering consistency and reducing errors.

- RFID (Radio Frequency Identification) Technology: RFID tags embedded in food packaging offer enhanced traceability as they can track food products throughout the supply chain in real-time.

SATO: Empowering Businesses with Food Safety Labeling Solutions

Not all label printers are created equal. SATO food safety label printers are a top-shelf choice in the food and grocery industry for their durability, resistance to moisture and temperature fluctuations, and crisp, clear label printing. Here are a few reasons SATO printers remain a top choice for food manufacturers and retailers:

Improved Efficiency: High-speed printing and easy integration with existing systems streamline labeling processes, reducing bottlenecks and improving overall productivity.

Enhanced Traceability: Accurate and legible labels facilitate effective tracking of food products throughout the supply chain, ensuring compliance with regulatory requirements.

Durability and Reliability: SATO printers are built to withstand tough conditions, ensuring uninterrupted operation in food production environments.

Versatility: The printers can accommodate a wide range of label materials and printing applications, meeting the diverse needs of the food industry.

SATO is the innovator behind DateRight™ Rotation Labeling, a solution to streamline food storage and rotation in food service outlets. The label incorporates seven color indicators that represent the days of the week, allowing for easy visual identification of expiring products and promoting FIFO (First-In, First-Out) inventory management.

Let’s explore two popular food label printer models by SATO, the CL4NX Plus and CT4-LX printers.

SATO CL4NX Plus RFID Label Printer:

High-Speed Printing: The CL4NX Plus delivers rapid printing speeds up to 10 ips, reducing labeling bottlenecks and improving overall production efficiency.

UHF RFID Module: Print text and barcodes on UHF tags/labels and encode data in their embedded chips at the same time. The CL4NX Plus is even capable of checking RFID chips prior to encoding to verify their readiness to use and to prevent failures.

Flexible Media Handling: The printer can accommodate a wide range of label materials, including those with special coatings or adhesives, ensuring compatibility with various food packaging applications.

Advanced Connectivity Options: The CL4NX Plus offers seamless integration with existing systems, enabling efficient data transfer and label printing.

Learn more about the SATO CL4NX Plus.

SATO CT4-LX Label Printer:

- Compact and Portable: The CT4-LX is a 4-inch compact and portable printer, making it ideal for mobile labeling applications in food production facilities.

- Patented Label Waste Prevention: SATO’s patented label waste prevention feature helps minimize label waste, contributing to cost savings and environmental sustainability.

- High-Resolution Printing: The printer delivers clear and legible labels, ensuring accurate product information and traceability.

- Wireless Connectivity: The CT4-LX offers wireless connectivity options, enabling mobile workers to print labels from remote locations.

Learn more about the SATO CT4-LX.

By incorporating high-quality food label printers like the SATO CL4NX Plus RFID and CT4-LX printers into their operations, businesses can enhance food safety labeling practices, improve efficiency, and ensure compliance with regulatory standards. Barcodes, Inc. is a leader in supply chain solutions, offering high-quality thermal printers and compatible labels specifically designed for unique industries. For help finding the right labeling solutions for your business, contact Barcodes Inc. today.

The How and Why of RAIN RFID Cryptographic Authentication

The problem of counterfeit products is global, and it’s growing. Knockoff handbags, athletic shoes, wristwatches, and pharmaceuticals cost businesses and consumers billions of dollars every year globally.

Now, there’s a new way brands can fight fakes: RAIN RFID cryptographic authentication.

The Impinj Authenticityâ„¢ solution engine brings enterprise-scale product authentication to new and existing RAIN RFID deployments.

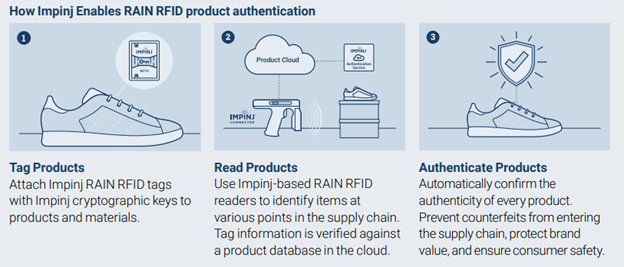

What is Product Authentication?

At its heart, authenticating something is largely straightforward: You want to conclusively establish the item as genuine and determine its owner or origin. Doing that can get complex.

Product authentication solutions built on the Impinj platform employ secure cryptography, using a challenge-response protocol to determine with a high degree of certainty whether an item is genuine.

RAIN RFID from Impinj

An item tagged with RAIN RFID has certain information associated with it—data such as the manufacturer name, model number, serial number, date of manufacture, purchase date, customer name, and more. That item-specific data can be stored in a product cloud.

When that item is read at any point in the supply chain by a RAIN RFID reader, an Impinj-based authentication solution cross-checks and confirms the information stored in the product cloud and verifies the tag’s authenticity using the Impinj Authentication Service.

Impinj Authenticity uses cryptographic authentication, a feature of the new RFID tag chips, to swiftly and automatically verify tagged products as genuine.

Implement RAIN RFID with a Trusted Partner

For an in-depth explanation of how Impinj Authenticity works, contact Barcodes, Inc. to learn more about RAIN RFID.

RFID Webinar: Improve Returnable Container Tracking with RFID

Webinar

Improve Returnable Container Tracking with RFID

Thursday April 20th 1:00-1:45pm Central

PRESENTED BY:

Christopher Vassilos – Senior Solutions Architect, Barcodes Group

Michael Daily – Senior Solutions Engineer, Impinj

RFID-Based Container Tracking

Upon delivery, it’s common for reusable containers to not be returned to the sender, with annual shrinkage rates often exceeding 10%. Keeping track of your Returnable Transport Items (RTIs) can be challenging, especially when logging their location depends on manual processes like scanning.

In this webinar, discover the benefits of RFID-based container tracking:

- Reduce the number of misplaced pallets, kegs, and boxes. Less new delivery assets need to be purchased, and shipments are not interrupted due to lack of totes.

- Track each asset as it leaves and returns to the warehouse, allowing you to determine its exact location immediately and whether they have yet to return.

- Calculate the flow of returnable assets to fully understand your shipping capacity for the present and future.

- Improve utilization of workers since it takes way less time to scan RFID tags than barcodes, due to its fully automatable reading without line-of-sight requirements.