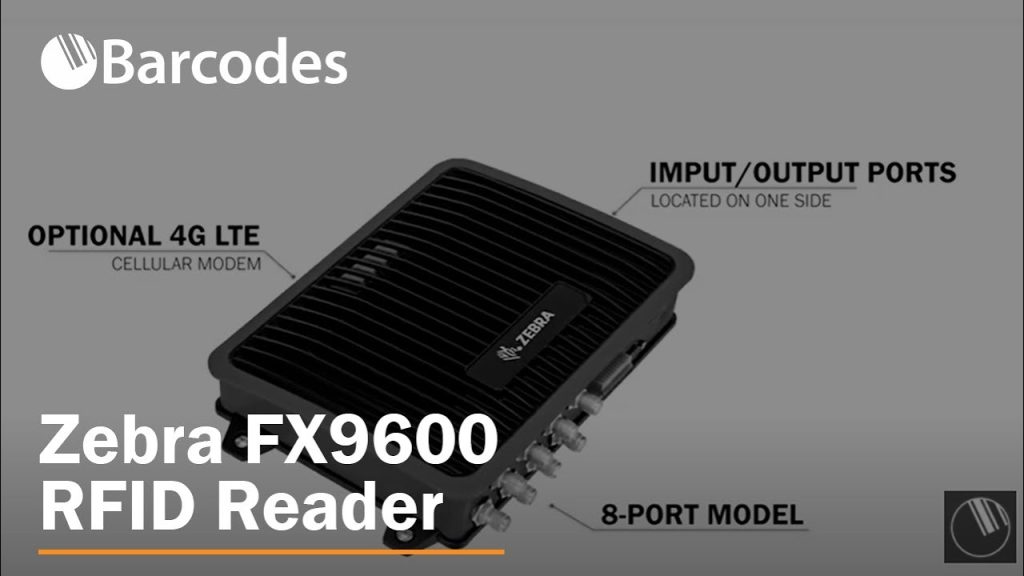

The FX9600 RFID Reader is Zebra’s Latest Industrial Workhorse

The FX9600 RFID reader from Zebra Technologies delivers exceptionally high sensitivity and top performance, designed for high-volume, industrial environments.

To achieve maximum visibility and efficiency in your most rugged environments, your business needs an RFID reader that can keep up with the high volume and wide variety of pallets, cases and tagged items that go in, out, and through your warehouse each day.

The Zebra FX9600 Fixed UHF RFID Reader delivers the performance and features you need to handle it all. The extremely durable diecast aluminum housing and IP53 sealing deliver the rugged design you need to ensure uptime in your most challenging areas.

The FX9600 reader can host embedded applications, simplifying and reducing deployment time, cost, and complexity while increasing network bandwidth.

See the FX9600 RFID Reader in Action

With industry-leading read rates, long read ranges, and exceptional RF sensitivity, you can automate inventory management from start to finish. Receiving and storing, picking and shipping – all without errors, and without bottlenecks.

The result? Increased efficiency and accuracy every time your inventory is touched, reducing labor costs and ensuring the delivery of the right product to the right customer, on time, every time. See even more warehouse management RFID solutions from Barcodes.

For Industry-Best RFID Reader Performance, the FX9600 Delivers

Zebra Technologies is committed to supporting a variety of warehouse needs. The FX9600 enhances workforce functionality in the following ways:

- Exceptional RF sensitivity

- IP53 sealing and up to eight RF ports

- Durable diecast aluminum housing

- PoE and PoE+ support

Meet the RFID reader that’s a step above the rest. [Download FX9600 RFID Infographic Sheet]

With functionality and performance in mind, Zebra delivers industry-leading RFID readers capable of hitting the mark for warehouse needs. Contact us today to see how you can bring greater efficiency to your workforce with RFID.

The Walmart Mandate: Tipping Point for RFID Adoption? (Webinar)

Webinar:

The Walmart Mandate: Tipping Point for RFID Adoption?

Thursday, May 12th, 2:00 P.M. – 2:30 P.M. ET

Presented By:

Todd Muscato – Barcodes Group

Ashley Burkle – Impinj

Ensure Your RFID Labels and Tags are Compliant Before September Deadline

After success using RFID for apparel, Walmart is expanding its RFID mandate to scores of additional products. Could it be a tipping point for RFID adoption in U.S. retail?

With heightened omnichannel demands and continued supply chain disruptions, retailers with inventory accuracy and visibility are thriving. How do you thrive instead of just survive with RFID in retail?

In this webinar, Barcodes and Impinj discuss the following:

- How RFID is helping big brand retailers adapt and thrive

- What retailers and their suppliers need to get started on their RFID journey

- How Barcodes can help with RFID solutions, including devices, software, tags, and support

Watch the Retail RFID Webinar Recording

Learn more about Barcodes’ Walmart RFID solutions, and contact us if you would like to have an exploratory discussion.

The Smart Warehouse (Webinar)

Webinar:

The Smart Warehouse

Thursday, April 20, 12 P.M. ET

Presented By:

Will Barnett – Barcodes Group

Jeff Lem – Portable Intelligence

John Wirthlin – Zebra Technologies

Ensure Your RFID Labels and Tags are Compliant Before September Deadline

There are many challenges facing warehouses today. An increase of growth and demand accompanied by a shortage of labor and supply chain instability have industry executives looking for new ways to help alleviate these issues. In this webinar, we’ll discuss warehousing trends and technology that help increase operational efficiency, including:

- The 5 Phases of Zebra’s Warehouse Maturity Model

- Strategies to reduce inventory levels

- Ways to improve your cycle counts and reduce inventory obsolescence

Watch the Full Smart Warehouse Webinar

Let’s discuss technology upgrades in your warehouse and your business goals. The Smart Warehouse is much more attainable with trusted partners like Barcodes, Zebra, and Portable Intelligence.

How RFID Increases Shipment Accuracy (Webinar)

Webinar:

How RFID Increases Shipment Accuracy

Thursday, March 24, 2022

Presented By:

Jeff Hudson – Barcodes Group

Matt Seltz – Zebra Technologies

Reduce Shipping Chargebacks with Integrated RFID Portal Solutions from Zebra and Barcodes

When your inventory is hard to identify or locate in the warehouse, it leads to incomplete, inaccurate, or delayed shipments. The annual cost of chargebacks due to mistakes in shipping is estimated to be $36B.

Reading RFID tags as they pass through portals or chokepoints is quickly becoming the most efficient and effective means of automating inventory and asset tracking.

Easy to implement and support, Zebra’s new Integrated RFID Portals easily validate shipments as they are loaded on or unloaded from trucks.

During this webinar, we discuss the following ways in which RFID increases shipment accuracy:

- Why RFID drastically reduces the need for human intervention and manual scanning

- What steps companies take to reach a 25% efficiency increase with RFID

- How Zebra’s new Integrated RFID Portals monitor inventory, control costs, and optimize workflows

Watch the Webinar Recording

RFID is a key technology platform that we would love to discuss in more depth with you. In a landscape with lingering supply chain delays and rising labor costs, RFID is one of the most cost effective, scalable, and reliable solutions available today. Learn more about Barcodes’ RFID solutions, and contact us if you would like to have an exploratory discussion.

6 Ways Enterprise Mobility is Empowering Fast-Paced Warehouses

It is estimated that nearly 73% of organizations plan to begin warehouse modernization by equipping workers with mobile devices. Increasing demand for faster and more accurate order fulfillment is a major contributor to this trend, despite fluctuating labor turnover rates. To keep warehouses ahead of demand, enterprise mobility solutions should aim at:

- Validating incoming inventory to establish accurate stock counts as products arrive.

- Streamlining put away, picking, packing, and shipping to prevent misplacements and lost stock.

- Enhancing your reverse logistics process for seamless returns since most shoppers expect easy and free returns.

- Simplifying inventory management and replenishment to avoid out-of-stocks.

- Scaling up theft prevention capabilities with clear real-time tracking and counterfeit prevention.

- Gaining universal mobile device management and support for maximized uptime.

Watch the video to see how Barcodes, Inc. and Zebra Technologies reinvent enterprise mobility in your warehouse.

To maximize your operational output, especially with labor shortages, you’ll need to rely on more powerful mobility technology and more efficient processes.

Implementing mobile devices is only the first step towards ensuring your warehouse’s future success. By partnering with Zebra Technologies, Barcodes, Inc. establishes a centralized hub where products flow to the market with ease, accuracy, and convenience. Examples include:

- Simplified receiving and picking – Ensure inventory accuracy with versatile mobile computers and RFID technology.

- Mis-shipment prevention – Save time and improve customer satisfaction with devices that scan and verify items as they’re packed to ensure on-time, accurate deliveries.

- Accelerated return process – Optimize the value of returned items and reduce revenue loss by accurately tracking and storing returned items.

- Streamlined inventory level verification – Leverage robots and wearable technology to quickly track inventory, reduce waste, and improve accuracy in the reordering process.

- Expanded asset visibility – Utilize RFID technology and smart lockers to increase mobile device visibility and prevent lost or stolen assets.

- Ensured interconnectivity – Integrate all apps and devices on the same, secure wireless network.

Download our flyer to see more ways Barcodes, Inc. continues to redefine modernized warehousing.

Choose Barcodes, Inc. and Zebra Technologies for your future warehouse solution. Contact us today to learn more about Barcodes, Inc.’s EDGE that maximizes your warehouse success with mobile device management.

5 Ways Traceability Can Improve Your Manufacturing Plant

Traceability and visibility are crucial measures for your manufacturing operation and production line. Proper traceability and visibility increase efficiency in the production line by catching defects before they leave the plant, thus reducing recall costs and effects. Without complete visibility, traceability systems will fail to report inaccuracies.

In fact, 69% of companies do not have total visibility over their supply chains, which leads many scrambling to prove everything is up to code during audits and inspections. When defects are identified in a product, organizations need to sort through mounds of data to track and trace raw materials. Otherwise, they may be facing a mass recall. These errors can cost your business millions of dollars, but the good news is that they are avoidable.

Effective tracking and locationing technologies empower manufacturing facilities to deliver fast, accurate, and quality service that secures efficiency for the whole supply chain. See how in our video:

Ensure Proper Tracing and Accurate Visibility with Barcodes, Inc.

Proper tracing and accurate visibility are key components to the well-being of manufacturing plants. Barcodes, Inc. ensures that your manufacturing plant is up to date with integrated solutions. Here are some ways proper tracing and visibility can impact your business.

- Streamline cause analysis – Having access to the data on your products enables manufacturers to dig deep and find the root cause of problems. Identify and solve problems faster to minimize impact.

- Consistent improvement – Once you are able to see how parts and products move through lines, it’s easier to see where improvement is needed. Knowing where and when bottlenecks and delays occur makes real-time optimization possible.

- Enhance your value stream – Since traceability and visibility monitors how your products move through your manufacturing process, it also helps with value stream mapping. Equipped with detailed product genealogy records, manufacturers gain supply chain visibility, which provides your operation the ability to see the bigger picture.

- Quality and engagement – Part traceability along the entire production line can also help find key points where quality check-ups should be added. It also increases accountability and engagement on the shop floor.

- Simple real-time tracking – Easy-to-use technologies such as Zebra’s locationing hardware simplify on-the-fly tracking of your high demand inventory, by digitally connecting data to your centralized management system. This means workers spend less time looking through files and reports for faster and more accurate audits.

Download our brochure to see more ways effective tracking enhances the production floor.

Contact us today to learn more about RFID technology designed to maximize traceability and visibility in your manufacturing plant.

How to Add an Extra Layer of Mobility to Your RFID Tracking System

Given today’s changing customer demands, new safety regulations, and the e-commerce boost, managing inventory continues to be a struggle for most warehouses and distribution centers. As a result, RFID has remained popular across industries since it accelerates throughput while increasing accuracy rates in both the receiving and loading docks. To take RFID efficiency a step farther, we recommend integrating it into your mobile printers with the ZQ630 and ZQ630 RFID:

Why combine mobility and visibility?

Inventory management has been cited as one the top struggles warehouses face today, which means solutions simplifying inventory management can help sharpen your competitive edge. A few issues that further complicate efficient management are:

- Sudden demand increases

- Lagging stock updated that leads to stockouts

- Increasing labor turnover rates that lead to high adoption rates for new technologies

- Lack of real-time visibility

By empowering your workforce with mobile RFID devices, you are able to streamline crucial tasks such as data capture, data sharing, and even label printing, ultimately delivering real-time updates across every avenue your workforce uses. For example, RFID mobile printing allows you to:

- Print updated RFID tags anywhere in your workflow in the event of sudden demand spikes

- Decrease processing time by eliminating unnecessary travel paths

- Deploy an end-to-end tracking system with easy-to-use devices for faster onboarding

- Label incoming inventory immediately with RFID tags to start tracking stock in real-time

- Lower employee density in printing stations

- Increase mobility with lightweight enterprise-grade devices

Working alongside your team, Barcodes, Inc. assists with design, deployment and support services to maximize printer uptime, so your workforce can confidently manage inventory with tools that move with them. Contact us today for a free consultation to see where can implement RFID mobility in your operations.

Where to Place an RFID Inlay

Printing and encoding RFID “smart labels” with an RFID-enabled printer has traditionally been difficult; a classic case of “the Devil is in the details.” One difficulty users have wrestled with has been “inlay placement.” Inlay placement refers to the location of the RFID inlay under the label’s face stock. Although inlays are generally oriented horizontally under the face stock, the inlays can be located towards the bottom of the label, towards the top, or anywhere in between. In the picture to the right, for example, the inlay is relatively close to the bottom of the label, the “leading edge” as it is often called, because this edge comes out of the printer first.

Almost every printer brand – and even model – has traditionally had detailed, complex specifications regarding inlay placement, with different specifications for each and every inlay on the market. The location of the inlay has to be a particular distance from the leading edge of the label in order to maximize the printer’s throughput (speed). Just a millimeter or two either way, and the performance of the printer can suffer dramatically. What a mess. Given that printing and encoding RFID labels is already slower than printing traditional barcode labels, any further loss in performance has often been catastrophic for the end-user. Waiting for your RFID labels to print and encode can hold up an entire production line. This all meant that for your printer brand and model, you needed to make sure to order labels with an optimal inlay placement.

Precise inlay placement also causes some additional problems:

- It makes selecting labels more difficult. Users need to order their labels very carefully to ensure correct inlay placement. Does your purchasing department understand inlay placement?

- It can cause delays in sourcing labels. Often, a convertor (label manufacturer) will have exactly the label size you need – but with incorrect inlay placement for your printer. To get labels with optimal inlay placement, the convertor needs to configure their entire production line and run a new batch of labels for you. This can take several days to several weeks.

- Finally, requiring a specific inlay placement can mean that users may pay more for their labels. A quick Google search of classic paper thermal transfer 4×6 RFID shipping labels will show some surprising results. The very same labels from the very same vendor can have dramatically different prices depending solely on inlay placement. It all boils down to supply and demand, but if you are on the wrong side of the equation, you may have to pay significantly more for your labels.

With Printronix Auto ID’s current line-up of RFID printers, these headaches associated with inlay placement are now a thing of the past. Printronix RFID printers have a unique firmware (the software brains in the printer), which does what they call “Encode During Print.” In clearer language, this means that the printer will first print some of the label, then switch over to encoding, then switch back to printing and finish up the label. The printer will automatically either print or encode at any given moment depending on where the label is relative to the printer’s printhead and RFID encoder. The traditional approaches for RFID printers were to either first print the entire label, then encode the RFID portion (“Print then Encode”) – or to first encode the RFID, then print the label (“Encode then Print”). But with these traditional approaches, if the inlay is not optimally placed, then the printer needs to back- or forward-feed the label to align it for an operation (printing or encoding) at any given moment. With Printronix’s Encode During Print functionality, back- and forward-feed are eliminated (other than to overstrike bad labels, which is another blog topic for another day), regardless of inlay placement.

So far, we have been talking about labels like 4×6 shipping labels that allow different inlay placements. But what about all of the RFID labels, “tags,” on the market that have predetermined inlay placement? For example, on-metal tags, plant stakes, small pharmaceutical labels for cold-chain applications, “RTI” tags (Returnable Transport Items), etc., etc. There are many such tags on the market, and more are being developed and released all the time. These tags generally have a fixed inlay placement based on their physical design and on simple commercial considerations – they are meant to be “Off-the-Shelf” (OTS) products. This is another area Printronix’s Encode During Print functionality shines even more. Because the Printronix printers do not care where the inlay is located, you can use any of these tags and still achieve maximum throughput.

And these unusual tags often pose physical feed challenges for RFID printers. For example, on-metal and RTI tags are often thicker than normal smart labels, and they can have abrupt edges between labels, large gaps, etc. Both Printronix’s T6000e and T4000 series printers were designed from the ground up to work with these more difficult constructions. The printers are spec’ed for labels up to 1.2mm thick and are available in 4” and 6” print-widths, allowing you to print and encode a wide variety of tags from a single printer – all without sacrificing performance.

Finding the right RFID solution is always a challenge and having the right resources and help are critical. If RFID sounds like a suitable solution for your business or you have additional questions, feel free to contact us at Barcodes, Inc. We’re always happy to help you find the right solution for your needs.

The Next Generation 4-inch Desktop Thermal Printer

Setting the bar for desktop barcode label printing, SATO’s CT4-LX is a 4-inch thermal printer offering features and functionality typically only found in industrial printer models but in a compact size. Designed with a full-color touchscreen display, the latest wireless connectivity options and patented label waste prevention feature, the CT4LX Label Printer is easy to operate and maintain with user-replaceable printheads and platen rollers to quickly keep your business up and running.

Key Features

– 4.3″ Full Color Touchscreen Display

– 203 or 305 dpi print resolution

– Thermal Transfer and Direct Thermal

– Label Waste Prevention – eliminates first label loss

– Apple iOS Connectivity

– Quick pairing with NFC-enabled devices

– Auto Switching competitive emulation languages (SBPL, SEPL, SZPL, SDPL, SIPL, or STCL)

– Auto RFID positioning with SATO RF Analyze (SRA)

– Remote management with SATO Online Services (SOS)

Connectivity Options: USB, Ethernet, Wi-Fi, Bluetooth, RS-232C

Optional Features: UHF RFID encoder (pre-installed), Auto-Cutter, Linerless Cutter, Dispenser, Real-Time Clock

Shop the Sato CT4-LX online or Contact your Barcodes, Inc. Account Manager for more information.

ICYMI: Taking the Complexity out of Implementing RFID Solutions

In the manufacturing and distribution process, Radio Frequency Identification (RFID) solutions improve production times, increase inventory accuracy, reduce errors, better route information, and provide round-the-clock asset management.

Uncover how RFID can benefit your organization and review a proven approach for implementation. Whether you are new to the technology or looking to advance your RFID strategy, the presentation will give you a simplified view of what other companies in the industry are doing and how to get there.

In this webinar, you will learn the following:

- Why you should be considering RFID solutions

- See how other companies are implementing RFID to improve accuracy, visibility, and accountability within Manufacturing and Distribution

- Review a proven “Start Simple” approach for implementing RFID

- Introduction to RAPID RFID, a mobile and web-based fixed reader software product that takes the complexity out of implementing RFID solutions

- How Barcodes, Inc. and Vertical Systems can assist you in this process.

If you have any questions, please contact us here.