What Barcode Scanners Read Inverse (White on Black) Barcodes?

Datalogic Falcon X3 mobile computers with imager and Honeywell Xenon handheld barcode scanners read inverse barcodes. Inverse barcodes reverse the traditional barcode pattern from dark printing on a light surface to light printing on a dark surface.

A common use for inverse barcodes is retail merchandising. Graphic designers use inverse codes to adapt the barcode to match they style of the packaging. The barcode no longer has to be black on white label with a unique area. This blends the barcode more seamlessly with the product’s artwork.

In industrial environments, inverse codes help with reading Direct Part Marks (DPM). A DPM is often produced by etching or burning the part directly. The color produced by these processes will depend on the material with different metals or plastics providing an inverse result.

Contact us if you would like help selecting a barcode scanner or mobile computer that can read inverse barcodes.

QuickBooks Compatible Hardware

We’ve put together a page of QuickBooks compatible hardware to make it easy to find products that will work with your system.

The page includes QuickBooks barcode scanners, QuickBooks receipt printers and more.

What is OPOS?

A very common industry standard, OPOS enables programmers to write code once, but support any flavor of POS equipment (Star, Epson, Bixolon receipt printers, etc). Without it, developers would need to learn the specific command language for every single device manufacturer they wish to implement in their software, making integration a very long and painful process when one wants to support many products. For software vendors who want to be completely hardware independent, OPOS is one convenient way to go. Though each have separate purposes, the OPOS, JavaPOS, and POS for .NET standards fall under one collective name called UPOS (Unified Point of Sale), all of which is maintained by the NRF ARTS committee. Furthermore, OPOS isn’t just for receipt printer implementation; it supports 36 POS devices in total, including cash drawers, pole displays, pinpads, and etc.

Battery Life Tips for Mobile Computers

Get top performance from your Datalogic mobile computers by following these best practices for handling, charging, care and maintenance of installed battery bases.

Today’s mobile computers come with a full range of modern features which demand the best possible battery power to capitalize on. Whether you are using your mobile device for network communications, cell phone calls, internet access, barcode scanning, credit card transactions, GPS navigation, or color imaging, a dead battery will impact your productivity and ultimately affect total cost of ownership.

Datalogic has spent years studying the science of optimum mobile device performance, and we have compiled this documentation to help end users and administrators to employ proven battery management techniques to increase your operational success with our devices.

Disinfectant-Ready Barcode Scanner Enclosures for Healthcare Environments

In any area of a healthcare facility, the need to limit the spread of germs is critial to improve patient care and protect employees in direct contact with infected patients. This can be particularly important if the barcode scanner is traveling room-to-room on a medication cart, stationed in a high-traffic area, or used by multiple personnel. To protect patients and employees, shared equipment must always be kept in a clean, sanitary condition; yet, routine cleaning of data collection devices with harsh chemicals can erode plastic enclosures over time and potentially damage internal components.

To solve this challenge, Datalogic‘s Disinfectant-Ready enclosures are designed to withstand daily cleaning with harsh disinfectant chemical solutions to effectively fight germs and bacteria. These special plastic enclosures are treated with silver ion-based anti-microbial additives to earn their anti-microbial status. These additives have been proven to inhibit microbial growth on the scanner’s surface when tested against standards JIS Z 2801:2000. This standard is internationally recognized by the healthcare industry and certifies that specific germs and other micro-organisms are inhibited by the silver ion-based additives. Datalogic’s Disinfectant-Ready enclosures are additionally coupled with industry leading IP sealing ratings to further protect the scanners internal components from intrusion by chemicals and other liquids.

Protect your technology investment as well as your patients and employees health with Disinfectant-Ready enclosures from Datalogic and ensure years of dependable and reliable scanning performance.

What is Thermal Transfer Barcode Printing?

By Tim Walker

Thermal Transfer

- Uses a ribbon to transfer ink to label

- Crisper printing (important for barcode compliance)

- Long life span for printed labels

- Wide range of media material types

- Ribbon protects printhead, prolonging its usage

- Used when label is needed for longer period of time

- Used when label is required to be exposed to harsh environments

Thermal Transfer works by having the printhead heat an ink ribbon. The ink is actually melted and transferred onto the label where it quickly solidifies forming the desired image. Notice in the video you can see where the ink has been transferred from the ribbon to the label. Since the ink is actually bonded to the label, Thermal Transfer has the advantage of creating a more permanent image on the label. The images also tend to be crisper, making it good for high definition text and barcodes. Thermal Transfer is used in applications where the label needs to have a longer lifespan than Direct Thermal can provide or has to exist in an environment, like direct sunlight, that would cause problems for Direct Thermal. The ribbon also contains a coating on the back that helps protect the printhead, extending the lifespan of the printhead.

What is Direct Thermal Barcode Printing?

By Tim Walker

The first concept we are going to look at is the difference between the two primary printing methods: Direct Thermal and Thermal Transfer. Both technologies have their advantages and disadvantages. Which one you chose is dictated by your needs. The good news is most barcode label printers, outside of the small desktops, have the ability to utilize both technologies.

Direct Thermal

- Uses special heat sensitive media

- Does not use a ribbon (advantage) but does not stand up to heat or light (disadvantage)

- Used for temporary labeling applications like shipping labels

- The chemical process that creates the image will fade over time

Why use a thermal barcode printer?

By Tim Walker

Why do I need a special printer just to print barcode labels? Customers often have existing printers they feel they should be able to use for their labeling needs. To understand the advantages of Thermal Barcode Printers, lets start by taking a look a couple of alternative printing options.

Dot Matrix

- Poor quality

- Can’t print small enough

- Too slow

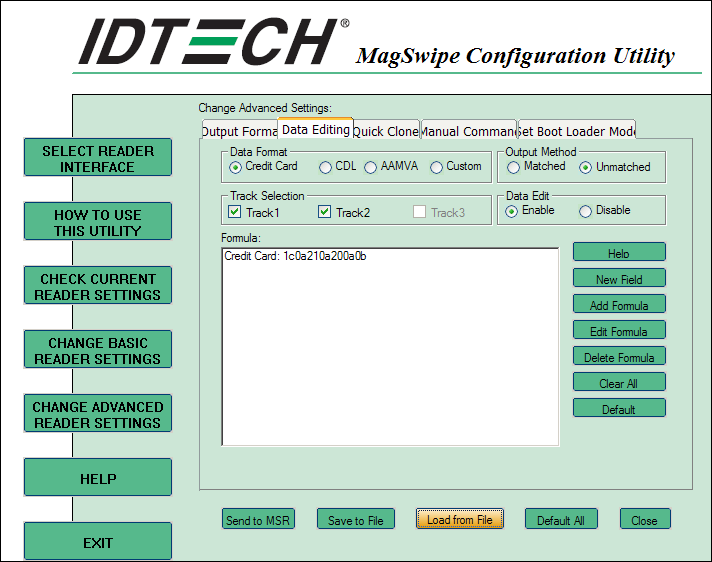

Configure an IDTech Credit Card Reader for PayPal Virtual Terminal

These directions will help you configure your IDTech credit card reader to automatically submit credit card information via the PayPal Virtual Terminal.

- Download paypal-virtual-terminal.cfs2 to your desktop or other easily accessible location.

- Download IDTech Configuration Software

- Install the IDTech Configuration software

- Plug your IDTech credit card reader into your computer

- Open the “MagSwipe Configuration Utility” from the Start Menu

- Click the “Change Advanced Reader Settings†button

- Click the “Data Editing” tab then click “Load from file†button

- Select the paypal-virtual-terminal.cfs2 file you downloaded in step #1

- Click “Send to MSR”

- Open the PayPal Virtual Terminal in your web browser

- Place your cursor in the “Credit Card Number” field

- Swipe credit card

- The card information should be submited and your browser will automatically go to “Review Transaction”

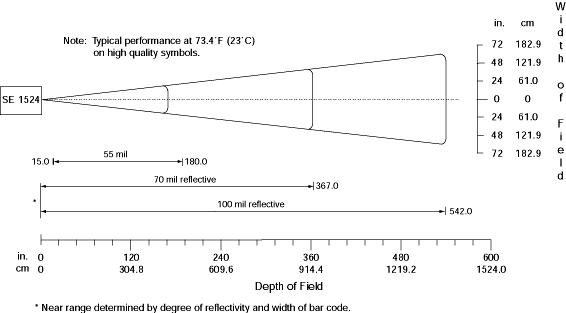

Decode Zone for the MC9000 Equipped with a Lorax 1D Long Range Barcode Scanner

The SE-1524ER “Lorax” is the barcode scanning engine that is used in some models of the Motorola MC9000 Series and other 1D long range barcode scanners. The SE-1524ER depth of field diagram shows the decode zone information.

With a large and reflective barcode, scans can be made successfully up to 45 feet away!