Why use a thermal barcode printer?

By Tim Walker

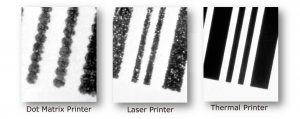

Why do I need a special printer just to print barcode labels? Customers often have existing printers they feel they should be able to use for their labeling needs. To understand the advantages of Thermal Barcode Printers, lets start by taking a look a couple of alternative printing options.

Dot Matrix

- Poor quality

- Can’t print small enough

- Too slow

Dot Matrix printers were designed with printing letters in mind. The original goal was to get the quality of print close to that of other impact printing methods (such as type writers.) While a dot matrix can print graphics and barcodes, it was not was they were designed to do. The quality of the barcodes will be poor, and the barcodes they can produce are large. Even the fastest Dot Matrix printers are slow when compared to other printing methods.

Laser Printers

- Print barcodes as graphics

- Has to print entire sheet

- Only prints on paper

- Still pretty slow

Laser Printers can be much faster than Dot Matrix or Ink Jet printers, and can print quality barcodes. However, here are three disadvantages to using Laser printers. The first is they print barcodes as graphics. If it fails to keep the ratios correct, then the barcode, no matter how nice looking, will not scan. Laser printers are designed to print an entire page at a time, which means they have to print an entire sheet of labels. Since most customers labels are not 8.5 by 11 inches, they cannot print just a single label. They get the whole sheet or nothing. Then final disadvantage to laser printers is they are designed to print on paper. While certainly most Thermal Barcode Printers printer are used with paper labels, there are a wide range of other stocks that can be used. This ranges from Synthetic materials such as Polypropylene and Polyester, that are used for labels that have to stand up to harsh environments, to wristbands and plant tags. This versatility is not possible with a laser printer.

Thermal Barcode Printers

- High quality text and graphics

- Very fast. Up to 12 in./sec

- Prints on demand – One label at a time

- Or, prints a whole roll for later use

- Prints high density bar codes (Down to 2.5 mils)

We have seen that there are alternatives when it comes to generating barcode labels, but when it comes to producing high quality barcode labels there is no better choice than a Thermal Barcode Printer. While laser printers can produce a scannable barcode, Thermal Barcode Printers can generate barcodes internally. They do not treat the barcode as a graphic, which can be distorted, but natively process and print barcodes, guaranteeing the barcodes meet all the relevant specifications.

Other advantages for Thermal Barcode Printers

- Speed: Thermal Printer’s speed is measured in Inches Per Second (IPS). At 12 IPS the printer is generating 2 4×6 shipping labels every second.

- Print on Demand: Unlike a laser printer, Thermal Barcode Printers have the ability to print a single label at a time. Perfect for those applications (such as shipping) where only a single label is needed at a time. Batch printing with a rewinder enables labels to be printed ahead of time in mass.

- Resolution: A Thermal Barcode Printers with a high resolution printhead can print high density barcode. With a 600dpi printhead a high quality 2.5 mil barcode can be generated. For those of you that have had a chance to see ScanSource’s Barcode Basics Presentation, 2.5 mils is very small.

- Alternative media: With Thermal Barcode Printers you are not limited to just printing paper labels. As we will see later on, a wide range of materials and form factors are available.

This image clearly illustrates the distinct quality difference between thermal barcode printers and their competition when it comes to printing barcodes. Remember the crisper and straighter the edges and the higher the contrast between the black bars and the white spaces, the better the barcode.