Tech Tips: Endorsement, Slip, and Validation Printing

The standard thermal receipt printer that populates most POS checkout lanes today is a single function device for making simple receipts. While this may fill the needs of a basic POS system, there are several types of additional printing that some printers can do for applications that need to also print on checks, return slips, prescriptions or other types of documentation.

The standard thermal receipt printer that populates most POS checkout lanes today is a single function device for making simple receipts. While this may fill the needs of a basic POS system, there are several types of additional printing that some printers can do for applications that need to also print on checks, return slips, prescriptions or other types of documentation.

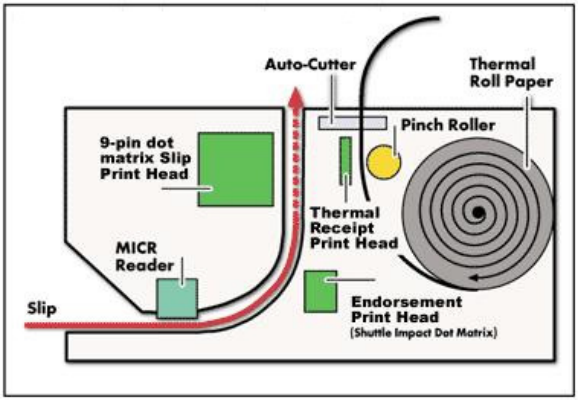

The multi-function printers come in a variety of sizes and types with essentially 3 additional types of printing beyond the standard receipt printer.

Star Micronics Broadens WebPRNT SP700 and TSP700II Product Range

Since its initial launch in Fall 2013, WebPRNT has been one of Star’s most popular technologies. Its unique ability to enable device-agnostic receipt printing by supporting HTTP requests used in web-based applications sets it apart from other receipt printers. WebPRNT is equipped with Ethernet connectivity. Easy to read, maintain and modify; developers simply use the appropriate XML tags or integrate Star’s WebPRNT Javascript library into their web-based application to print to Star’s WebPRNT receipt printer.

Since its initial launch in Fall 2013, WebPRNT has been one of Star’s most popular technologies. Its unique ability to enable device-agnostic receipt printing by supporting HTTP requests used in web-based applications sets it apart from other receipt printers. WebPRNT is equipped with Ethernet connectivity. Easy to read, maintain and modify; developers simply use the appropriate XML tags or integrate Star’s WebPRNT Javascript library into their web-based application to print to Star’s WebPRNT receipt printer.

To meet customer demand, Star is adding SP700 (impact printing) and TSP700II (label printing) to its growing WebPRNT family.

How the Right Printer Can Make a Difference for Manufacturers

Information and documentation are essential components of everything that manufacturers produce and ship today, whether products need to be tracked through the production process or through the supply chain to the customer. Customer requests, regulatory requirements and efficient production processes all need information to flow along with products. While production is often automated, producing the necessary documentation often is not optimized.

Information and documentation are essential components of everything that manufacturers produce and ship today, whether products need to be tracked through the production process or through the supply chain to the customer. Customer requests, regulatory requirements and efficient production processes all need information to flow along with products. While production is often automated, producing the necessary documentation often is not optimized.

Producing the job tickets, component ID and product labels to provide this information is a growing challenge. Unless the process is streamlined with a proper printer and media, manufacturers are building unnecessary cost and inefficiency into every product. This post will explain how manufacturers can realize tangible improvement. It covers:

- How production processes can be improved by using printed labels and job tickets;

- Why sharing a general-purpose printer for office and production printing is an inefficient arrangement;

- How a dedicated thermal printer can reduce costs and errors.

Maximizing the Image Life of Direct Thermal Receipts and Wristbands

Direct thermal printing dates back to the 1960s and was originally designed for copiers and fax machines that utilize chemically coated paper. It has since been transformed into a highly successful print technology for bar coding.

Direct thermal media is essentially a self-contained printing system. It is manufactured by applying surface coatings to the media with a chemical formula that includes colorless dyes and developers. When the media goes through a thermal printer, heat (thermal energy) from the thermal printhead causes the dye and developer to activate and form a high-definition image. The thermal printhead consists of many heating elements distributed along its printing width. Each element is electronically controlled to deliver the correct amount of energy to an exact location for an exact amount of time. Those individual elements are strobed by the printer to form the final image—text, graphics, and bar codes. Fully saturating or imaging direct thermal chemistry is key to obtaining the most durable direct thermal image. Producing a less than fully saturated image will reduce the image life when exposed to various contaminants or environmental conditions.