Maximizing the Image Life of Direct Thermal Receipts and Wristbands

Direct thermal printing dates back to the 1960s and was originally designed for copiers and fax machines that utilize chemically coated paper. It has since been transformed into a highly successful print technology for bar coding.

Direct thermal media is essentially a self-contained printing system. It is manufactured by applying surface coatings to the media with a chemical formula that includes colorless dyes and developers. When the media goes through a thermal printer, heat (thermal energy) from the thermal printhead causes the dye and developer to activate and form a high-definition image. The thermal printhead consists of many heating elements distributed along its printing width. Each element is electronically controlled to deliver the correct amount of energy to an exact location for an exact amount of time. Those individual elements are strobed by the printer to form the final image—text, graphics, and bar codes. Fully saturating or imaging direct thermal chemistry is key to obtaining the most durable direct thermal image. Producing a less than fully saturated image will reduce the image life when exposed to various contaminants or environmental conditions.

Keys to Image Durability

While a fully saturated image looks similar to a less than fully saturated image, the durability of these images varies greatly. Therefore, it is important to understand that the direct thermal material being used, combined with the printer settings, determines the durability of a direct thermal image. In addition, it is also important to understand that the default setting of the printer may not always produce a fully saturated image. For that reason, any investigation of direct thermal image durability issues should include an evaluation of the printer settings, in conjunction with the material being utilized.

The key printer settings are the darkness or tone and the print speed. The darkness or tone setting determines how much the printhead is heated up. The print speed determines how fast the image prints.

Each direct thermal material has a different sensitivity level. The sensitivity level affects how much heat is needed to produce the image.

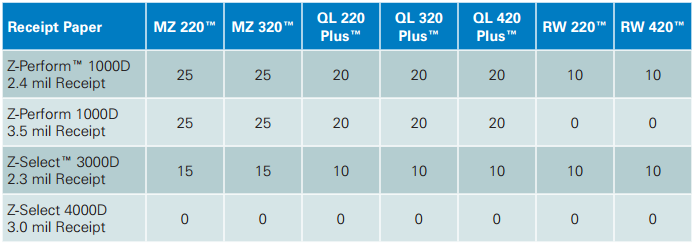

Zebra’s Supplies R&D Team has performed testing on genuine Zebra direct thermal receipt paper and wristbands to determine the proper setting for each printer to ensure a fully saturated image with the highest durability

Mobile Receipt Printers

Direct thermal receipt papers have archivability durations of up to 25 years (depending on the material), provided they are formed properly and the receipts are handled and stored under the proper conditions. For archival use, these receipts need to be protected from exposure to light, heat, water, solvents, cleaners, plasticizers (common sources are plastic bags and binders), and oils (including vegetable oils and skin oils), and they need to be stored with compatible materials at temperatures less than 70º F/21º C, and 35–50% relative humidity (RH). Image durability depends on the energy used to print the receipts. To maximize image durability, the receipts should be printed at or above the default energy settings.

Following are Zebra’s recommendations to ensure that the image on the receipt paper is fully saturated when

using genuine Zebra supplies:

Recommended settings:

- Speed: 3

- Contrast: 0

- Tone: see below

Wristband Printers

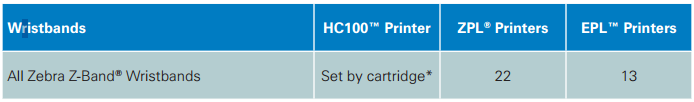

To ensure a wristband image lasts the length of a patient’s stay in a hospital, or a patron’s stay at an event or park, while being subjected to the harsh environmental conditions in these applications, the printer‘s settings must be modified from its default settings as recommended below.

Recommended Settings:

- Speed: 2 inches per second/50.8 mm per second

- Darkness: See below