Business Is Hard. Labeling Doesn’t Have To Be.

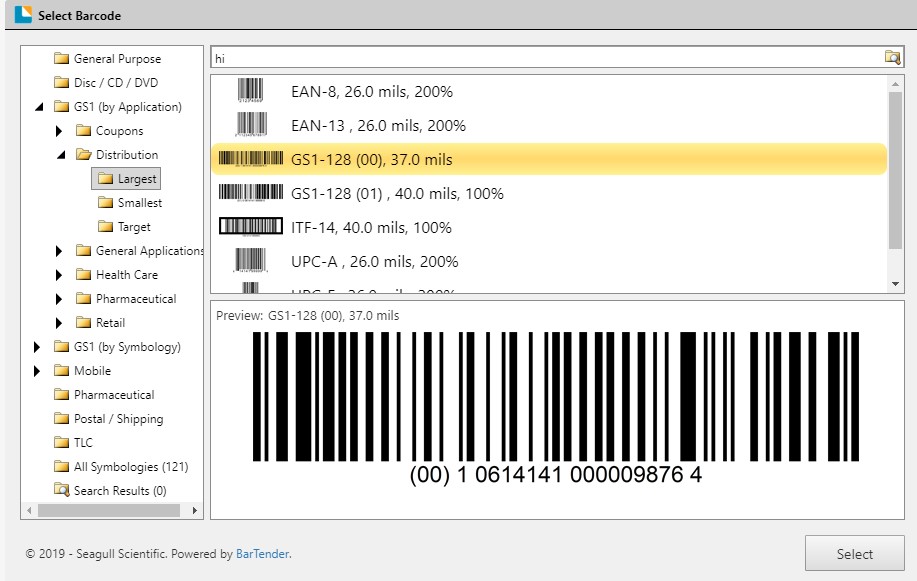

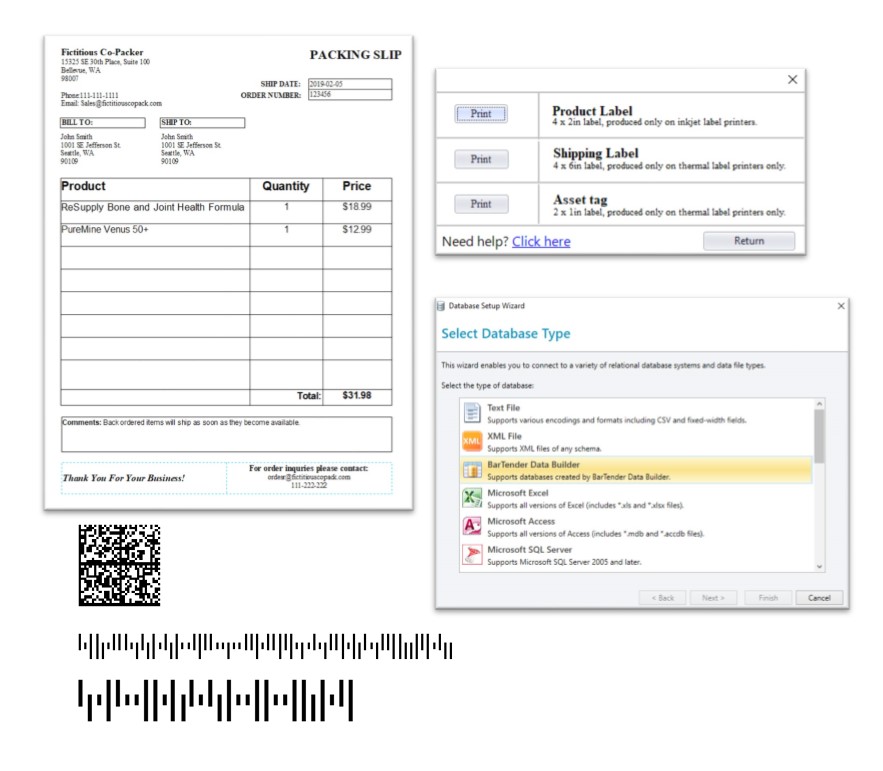

Introducing BarTender 2019, software from Seagull Scientific. With new capabilities to solve real- world problems and improve efficiency in your labeling operations. Organizations can improve safety, security, efficiency, and compliance by creating and automating the printing of labels, barcodes, RFID tags, plastic cards, and more.

With BarTender 2019 software you can print from spreadsheets or databases, print automatically, manage and secure your design and printing system, and manage your printings across different sites. Choose the software version that’s right for your business- Professional, Automation, and Enterprise.

BarTender 2019 new features (in addition to standard features):

- Grids, tables, easy text wrapping, and the ability to use multiple database records in a single document, enabling customers to leverage BarTender for packing slips, invoices, pallet labels, and more.

- Intelligent Forms enable the creation of complex print-time processes and automation.

- Data Builder provides a built-in database that makes it easy to create and manage data securely within BarTender, reducing the need to use external databases. (Customers who do use external data can now leverage improved connectors, write data back to most SQL-based databases, import data from an XML file, and use Azure-hosted databases.)

- Process Builder enables customers to easily automate many of their manual processes without extensive programming.

- Improved database connectors make it easier than ever to use data from existing business systems and formats such as XML, Azure SQL Database, and all versions of Microsoft Excel and Access.

Create. Automate. Manage

Create.

- Design and print, including packing slips and pallet labels.

- Easily enter print information with customizable data-entry forms

- Consolidate designs with Intelligent Templates

Automate.

- Print from any operating device, device, or web browser

- Create and print from business applicaitons

- Integrate with ease with SAP and Oracle

Manage.

- Centrally control and secure your labeling system

- Monitor print status in real time

- View detailed history of system usage

From manufacturing, chemicals, health care, food and beverages, aerospace, supply chains, logistics, to other industries that can enhance their design and printing experience to provide easier ways to manage and operate. Try it, contact Barcodes to enhance your printing experience, transform your labeling process to increase automation and efficiencies in your facilities.

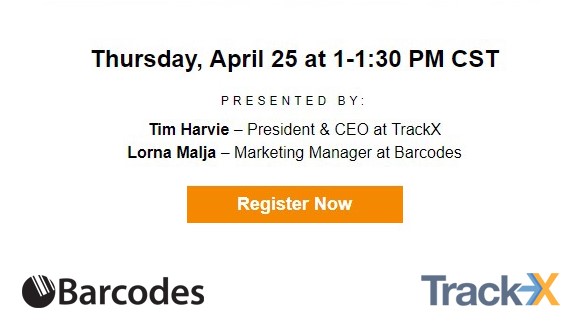

How To Track Returnable Assets to Drive Supply Chain Efficiency?

Join Barcodes and TrackX for our upcoming webinar, “Tracking Returnable Assets to Drive Supply Chain Efficiency”

where we will discuss how RFID tags and sensor data can drive business intelligence and improve inventory visibility.

Key Takeaways include:

- Improved asset utilization

- Reduction in shrink, loss and theft

- Brand protection and loyalty (increased customer service)

- Increased supply chain velocity

- Increased life of asset

If you have any questions, please contact us here.

We hope to see you there!

P.s. If you can’t make the live webinar, be sure to register anyways and we’ll send you the recording and slides afterwards!

Advantages of RFID for Retail

Apply the power of RFID (Radio frequency identification) in your retail environment! RFID technology goes beyond barcode scanning. It automates data collection without the risk of human error. With an RFID handheld scanner, you can read tags simultaneously and without direct line of sight increasing efficiency and productivity in a store.

All RFID tags within range can be tracked and located immediately to ensure the correct location from supply chain to on the floor. Retailers can have access to product information, item location, availability, item level tracking, stock maintenance to ensure greater efficiency and sufficient supply level to meet consumer demand.

Introducing the Alien ALR-S350 Sled RFID handheld reader, it is an robust, simple, cost effective RFID reader that is designed for all day use. Supports Apple iOS or Google Android via smart device you will be able to gain the flexibility and accuracy you need on the retail floor. Unlike competitive sled units, the Alien ALR-S350 RFID reader comes with everything required to begin to use, the kit comes with charging kit, cradle dock, and micro USB cable. All the user need is the smart phone or tablet device to bring visible information on the go.

Features:

- Capable of scanning 1D and 2D barcodes (QR codes)

- Reads up to 200 tags per second

- 3 LEDs and buzzer for user feedback

- Supports Apple iOS and Google Android Devices

- Robust Design IP54 feat Quadlock for phone mounting

- Bluetooth 4.2 connectivity for simple smart device pairing

- Up to 24 hours of intensive use- long battery life

Manually scanning barcodes or counting products is time extensive, employees must move aisle to aisle, locating items individually. With RFID scanners, workers can read tags as far as 20 feet away and at hundreds of tags per second. Contact Barcodes to learn more about how the Alien ALR-S350 Sled RFID reader can help you to increase accuracy and gain more visibility in your data collection.

Transform Janam’s XT2 Series Touch Computer into an RFID Reader

Turn your touch computer into a handheld RFID reader with the new Janam RFID sled for the XT2 Series! With the high-performance UHF RFID sled for the XT2 series touch computers you can snap it on and turn your mobile device into a RFID reader.

It has been proven that RFID can identify opportunities in a warehouse to enhance day to day operations. Workers can walk through the warehouse with Janam’s XT2 with RFID reader and be able to read multiple tags simultaneously from 22 feet away. That means they can scan an pallet of goods in a few seconds creating greater efficiency and productivity in the workforce.

Using RFID can improve inventory control along with eliminating errors and inaccuracies. RFID allows you to capture real-time inventory data which allows real time visibility of what materials are on the floor immediately in a fraction of the time it takes to capture data through bar code scanning.

- Powerful UHF RFID technology for tag writing and locationing

- Reads EPC Global Gen2 ISO 18000-6C RFID tags

- Own 3350mAh battery to ensure full shift power and eliminate downtime

- Lightest UHF RFID sled in its class

- Able to read a tag from more than 22 feet away

Watch the video below and see how the Janam’s XT2 Series and along with the new RFID sled can bring you more efficiency and visibility in your supply chain.

Contact us if you have any questions into improving your operational efficiency and decrease downtime in your workforce.

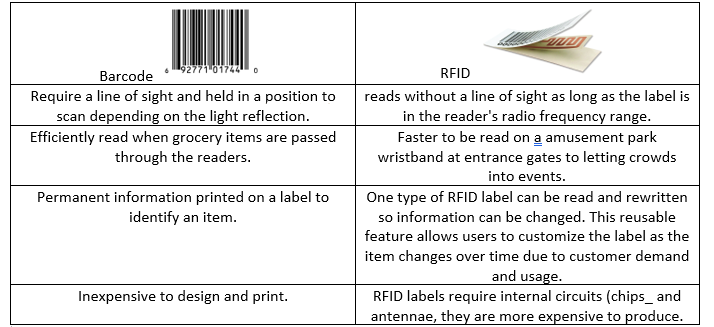

Barcode Vs. RFID: Things to Consider Before You Choose

Barcode and RFID labels are choices that enterprises must choose to improve efficiency. Which are the most cost- effective and reliable in the long run for your operation?

Here are a few things you should consider

Barcodes Vs. RFID

RFID labels have electronically generated unique codes and barcodes use standard protocols. In an inventory collection setting, a barcode label can tally up items in the stock according to product type, manufacturer, and stock level. Employees will have to manually check for item specifics such as color, price, and purchase date of individual items. On the other hand, RFID labels are capable of loading up 2,000 proprietary byte of information and be able to tally up individual items in inventory too.

For example: A barcode label would be able to tell a grocer how many gallons Milk A and Milk B was in the cooler but an RFID label will be able to disclose where each gallon of milk came from the farm and distributor.

Ultimately, if printer properly both barcode and RFID tags can eliminate human error and contribute to enterprise efficiency compare to when items are accounted for by hand. Purchasing either barcode or RFID solutions depends on the depth of data required by an enterprise and how the system will be used in the field. Label consumers have to make a decision based on the needs and financial constraints.

If you need guidance on which solution to choose, feel free to contact one of our dedicated account managers and we will be happy to help.

Metalcraft RFID Assest Tags Printed on SATO CL4NX