Streamlining Supply Chains with Barcodes and Loftware’s Integrated Solutions

In today’s complex global market, efficient supply chain management is more crucial than ever. With customer demands evolving and regulations tightening, managing supplier compliance effectively is essential for seamless operations. At Barcodes, in partnership with Loftware, we specialize in integrating sophisticated labeling solutions into customer printers, ensuring that each step of your supply chain is compliant and efficient.

Streamlining Supply Chains with Efficient Supplier Compliance

For large manufacturers, the web of processes and stakeholders involved in managing supplier goods is notably complex. From planning to execution, every step is critical to ensure smooth operations. Disruptions often occur during the physical handoff from suppliers, where costs can quickly escalate. For instance, our partner Loftware has observed significant expenses associated with the relabeling of supplier materials—costs that can be substantially reduced through more efficient processes.

The Challenge of Traditional Processes

Traditional methods, such as using Advanced Shipping Notices (ASNs), often fall short, leading to chaos in receiving departments due to inadequate information. Mislabeled items, incorrect receipts, and excess inventory lead to significant time and resource wastage. So, how can these challenges be overcome?

Cloud-Based Labeling: A Revolutionary Approach

Imagine a system where labeling is controlled beyond your organizational boundaries. With Loftware’s cloud-based labeling solutions, integrated seamlessly into your printers by Barcodes, this becomes a streamlined reality. This method allows for the direct application of your data, barcodes, and instructions onto the labeling process, ensuring that all inbound materials are accurately labeled according to your specifications.

The Power of Our Partnership

Barcodes and Loftware bring together the best of both worlds: advanced cloud-based labeling technology and expert integration services. This powerful combination ensures that:

- Seamless Integration and Support: Barcodes provides expert integration of Loftware’s solutions into your existing printer setups, ensuring a smooth transition and continuous support.

- Elimination of Relabeling Needs: By applying accurate labels from the outset, our solution eliminates the need and cost associated with relabeling.

- Increased Operational Efficiency: Our integrated solutions increase the velocity of inbound receiving, reducing delays and improving throughput.

- Reduced Inventory Overhead: Achieve Just-In-Time (JIT) inventory objectives by minimizing excess stock and related costs.

- Enhanced Supply Chain Visibility: With improved labeling accuracy and consistency, gain better insights into when supplies will arrive, enhancing overall planning and resource allocation.

- Future-Proof Operations: Standardizing on a centralized automated cloud platform through Loftware, with Barcodes’ integration expertise, enhances visibility, efficiency, and security across your supply chain.

Conclusion: Embrace Integrated Solutions, Enhance Supply Chain Compliance

By implementing barcoding technology and utilizing Loftware’s cloud-based labeling solutions, you can streamline your entire supply system while enhancing compliance and reducing costs. Ready to improve your supply chain efficiency?

FREE WEBINAR! Attend Loftware’s upcoming “Optimize Your Supply Chain Operations Through Supplier Compliance” webinar on May 16th, 2024, 1pm EDT / 10am PDT.

- Learn new and innovate ways to deliver business transformation & optimize your supply chain operations.

- Listen to industry experts discuss common challenges that hinder supply chain effectiveness.

- Discover how cloud-labeling solutions can significantly enhance your supply chain operations.

5 Ways Traceability Can Improve Your Manufacturing Plant

Traceability and visibility are crucial measures for your manufacturing operation and production line. Proper traceability and visibility increase efficiency in the production line by catching defects before they leave the plant, thus reducing recall costs and effects. Without complete visibility, traceability systems will fail to report inaccuracies.

In fact, 69% of companies do not have total visibility over their supply chains, which leads many scrambling to prove everything is up to code during audits and inspections. When defects are identified in a product, organizations need to sort through mounds of data to track and trace raw materials. Otherwise, they may be facing a mass recall. These errors can cost your business millions of dollars, but the good news is that they are avoidable.

Effective tracking and locationing technologies empower manufacturing facilities to deliver fast, accurate, and quality service that secures efficiency for the whole supply chain. See how in our video:

Ensure Proper Tracing and Accurate Visibility with Barcodes, Inc.

Proper tracing and accurate visibility are key components to the well-being of manufacturing plants. Barcodes, Inc. ensures that your manufacturing plant is up to date with integrated solutions. Here are some ways proper tracing and visibility can impact your business.

- Streamline cause analysis – Having access to the data on your products enables manufacturers to dig deep and find the root cause of problems. Identify and solve problems faster to minimize impact.

- Consistent improvement – Once you are able to see how parts and products move through lines, it’s easier to see where improvement is needed. Knowing where and when bottlenecks and delays occur makes real-time optimization possible.

- Enhance your value stream – Since traceability and visibility monitors how your products move through your manufacturing process, it also helps with value stream mapping. Equipped with detailed product genealogy records, manufacturers gain supply chain visibility, which provides your operation the ability to see the bigger picture.

- Quality and engagement – Part traceability along the entire production line can also help find key points where quality check-ups should be added. It also increases accountability and engagement on the shop floor.

- Simple real-time tracking – Easy-to-use technologies such as Zebra’s locationing hardware simplify on-the-fly tracking of your high demand inventory, by digitally connecting data to your centralized management system. This means workers spend less time looking through files and reports for faster and more accurate audits.

Download our brochure to see more ways effective tracking enhances the production floor.

Contact us today to learn more about RFID technology designed to maximize traceability and visibility in your manufacturing plant.

Keep your Operations Running at Maximum Efficiency

At Barcodes, we believe that the printing supplies for the hardware is just as important as the solution itself. Get the supplies you need whenever you need! From labels, ribbons, tags, and printheads you need to keep your barcode printers running to maximize workforce efficiency. With Zebra’s certified supplies you can ensure consistent, optimized performance with your printer and peace of mind for you. Zebra consumables brings value to your daily operations, all materials selected to create the supplies ensure consistent and high quality product. With consistency comes reliability that can keep your operations running. You will see smoother operations, increased productivity and efficiency at your workforce. Zebra’s selection of barcode labels, tags, and printheads meet the requirements of most applications and budget.

Choose from the list of Zebra consumables below:

- Barcode Labels

- Printheads

- Hospital wristbands

- Event wristbands

- RFID labels

- Ribbons

- Receipt paper

- Card printer cards

- Card printer ribbons

- Professional photo ID kit

- Custom supplies

Contact Barcodes we can keep your supplies in check and you can get the supplies you need whenever you need!

ICYMI: Tracking Returnable Assets to Drive Supply Chain Efficiency

In case you miss our webinar today, click on the video and discover how Barcodes and TrackX can help you drive business intelligence and improve inventory visibility with RFID tags and sensor data.

Key Takeaways include:

- Improved asset utilization

- Reduction in shrink, loss and theft

- Brand protection and loyalty (increased customer service)

- Increased supply chain velocity

- Increased life of asset

If you have any questions, please contact our marketing manager, Lorna Malja, at [email protected] or at 855-253-5508.

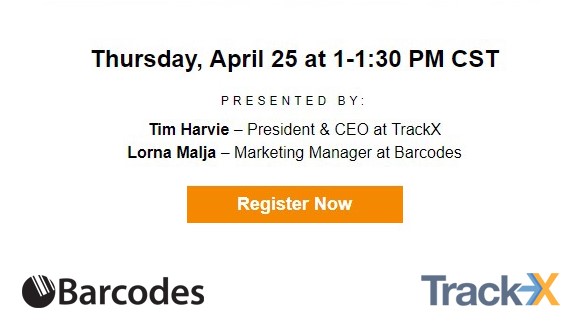

How To Track Returnable Assets to Drive Supply Chain Efficiency?

Join Barcodes and TrackX for our upcoming webinar, “Tracking Returnable Assets to Drive Supply Chain Efficiency”

where we will discuss how RFID tags and sensor data can drive business intelligence and improve inventory visibility.

Key Takeaways include:

- Improved asset utilization

- Reduction in shrink, loss and theft

- Brand protection and loyalty (increased customer service)

- Increased supply chain velocity

- Increased life of asset

If you have any questions, please contact us here.

We hope to see you there!

P.s. If you can’t make the live webinar, be sure to register anyways and we’ll send you the recording and slides afterwards!