Mobile Labeling Stations from Newcastle Systems Drastically Improve Warehouse Efficiency

Warehouse and fulfillment operations pose a great challenge any year, but consumer behavior during the pandemic has shifted heavily to online purchases. As a result, operations are handling larger inventories and more receipts, picks, shipments, and returns than ever before.

Meet the Demands of eCommerce Growth

While organizations focused on “keeping up” with demand, this was often at a higher cost (especially since many deprioritized process inefficiencies).

The eCommerce trend is not short-term. In Q1 2020, U.S. ecommerce sales climbed 39% over the same time last year, and growth projections already are nearly two years ahead of forecasts.

With demand still high, any inefficiencies in your processes will be exaggerated (and hence, more costly). Higher costs could mean serious limitations when scaling up your operations.

To optimize your warehouse for growth, small steps can make big impacts on your bottom-line costs, profit margin, even productivity – without significant investment in time, budget, or fancy software.

Ready to trim waste from your eCommerce operations? Get quick results with these five steps:

#1 – Establish a Cleaning Routine for Your Warehouse

Never underestimate the power of “clean.” Dust and dirt can damage product; empty pallets take up valuable space; and scrap boxes and strewn paper become obstacles and potential safety hazards that impede machine and people access, reduce productivity, and add extra steps as workers maneuver to avoid roadblocks. Implement an ongoing “clean routine” task list for your warehouse to streamline traffic and protect product – and workers.

#2 – Save Valuable Time with Cross-Docking

In eCommerce, there is a lot of pressure to ship items fast. If you have back ordered or single-item orders for certain products, you can save valuable time by skipping the restocking process. Instead, set up a process to relabel them for shipping right as they come off the truck on the receiving dock, and route them right back out the door of your shipping dock.

#3 – Simplify the Labeling Process

Labels have been around for decades, quietly getting inventory from point A to point B. Despite their importance, labels are perhaps one of the most underappreciated aspects of warehouse operations – and potentially one of the least efficient. Take time to audit and map your labeling process, paying particular attention to wasted motion, for example, the number of mouse clicks it takes to adjust formats, the number of trips a worker takes to/from the printer. Try to reduce the extra steps and work toward achieving an ideal mobile labeling process of Scan, Print, Apply. Mobile labeling stations, such as the Newcastle NB Series Nucleus System, help reduce walking and double employee productivity.

#4 – Organize SKU Location According to Volume

Certain items in your inventory may be more popular than others. For SKUs with higher order volumes or seasonal spikes, making them more accessible also makes processes more efficient. Location is key, so prioritize these items by placing them closer to packing for instance – and don’t forget to increase the bin size so stock doesn’t run low.

#5 – Reduce the Steps Required to Fill Orders

It may be hard to believe, but simply reducing the physical number of steps an employee takes to fill an order can result in significant cost and time savings. Converting a stationary workplace to a mobile one is the easiest, most economical way to increase the productivity of your current workers and infrastructure. Powered industrial carts, such as the line of products from Newcastle Systems, can hold and power printers, computers, and more to remove the tethers of a stationary workstation. This is everything workers need to get the job done right at their fingertips.

Improving Warehouse Efficiency

Efforts to optimize warehouse processes don’t have to be time-consuming or expensive. And doing so improves warehouse efficiency, and enables you to scale your operations successfully along with ecommerce growth. Whether you have interest in a specific solution from Newcastle, or have questions about general warehouse efficiency, don’t hesitate to contact us.

Business Is Hard. Labeling Doesn’t Have To Be.

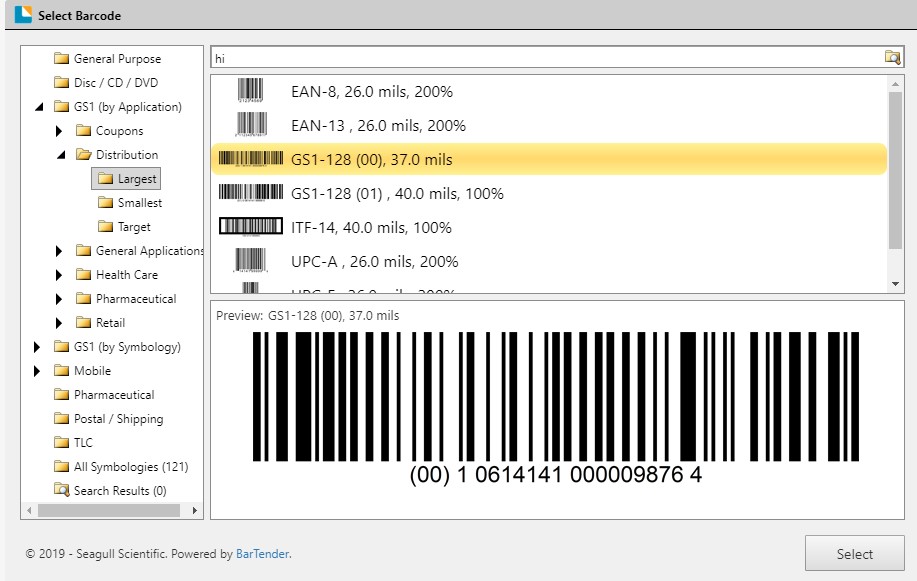

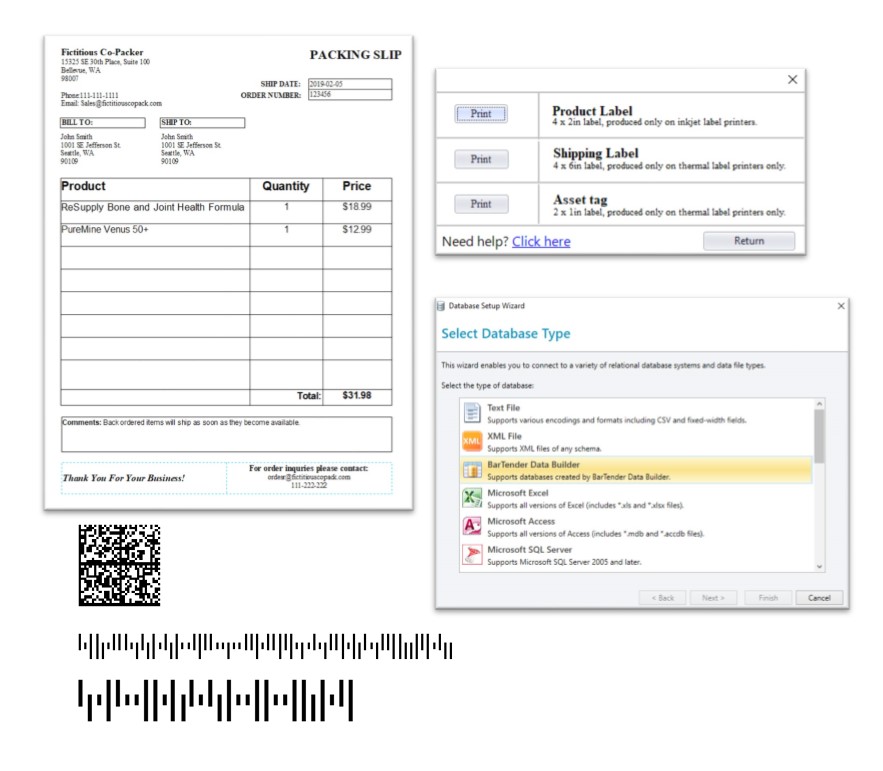

Introducing BarTender 2019, software from Seagull Scientific. With new capabilities to solve real- world problems and improve efficiency in your labeling operations. Organizations can improve safety, security, efficiency, and compliance by creating and automating the printing of labels, barcodes, RFID tags, plastic cards, and more.

With BarTender 2019 software you can print from spreadsheets or databases, print automatically, manage and secure your design and printing system, and manage your printings across different sites. Choose the software version that’s right for your business- Professional, Automation, and Enterprise.

BarTender 2019 new features (in addition to standard features):

- Grids, tables, easy text wrapping, and the ability to use multiple database records in a single document, enabling customers to leverage BarTender for packing slips, invoices, pallet labels, and more.

- Intelligent Forms enable the creation of complex print-time processes and automation.

- Data Builder provides a built-in database that makes it easy to create and manage data securely within BarTender, reducing the need to use external databases. (Customers who do use external data can now leverage improved connectors, write data back to most SQL-based databases, import data from an XML file, and use Azure-hosted databases.)

- Process Builder enables customers to easily automate many of their manual processes without extensive programming.

- Improved database connectors make it easier than ever to use data from existing business systems and formats such as XML, Azure SQL Database, and all versions of Microsoft Excel and Access.

Create. Automate. Manage

Create.

- Design and print, including packing slips and pallet labels.

- Easily enter print information with customizable data-entry forms

- Consolidate designs with Intelligent Templates

Automate.

- Print from any operating device, device, or web browser

- Create and print from business applicaitons

- Integrate with ease with SAP and Oracle

Manage.

- Centrally control and secure your labeling system

- Monitor print status in real time

- View detailed history of system usage

From manufacturing, chemicals, health care, food and beverages, aerospace, supply chains, logistics, to other industries that can enhance their design and printing experience to provide easier ways to manage and operate. Try it, contact Barcodes to enhance your printing experience, transform your labeling process to increase automation and efficiencies in your facilities.