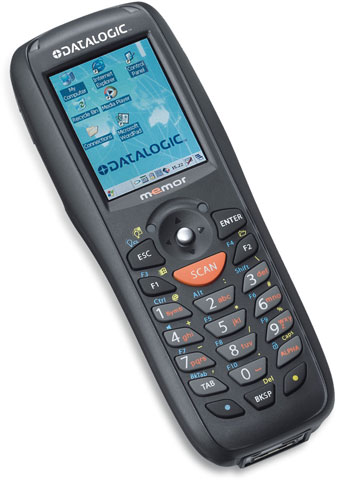

Trenor Chooses the Memor Mobile Computer for TOPSHOP and TOPMAN

Overview

Trenor Group is a fashion retailer with a franchise of brand stores. The company was founded in 2000 and is headquartered in Stockholm, Sweden. Thanks to an agreement with British fashion company Arcadia Group Ltd., a British retail giant in fashion, Trenor has a portfolio of many different brands, including the widely known TOPSHOPÂ and TOPMAN.

The Challenge

Both the TOPSHOP and TOPMAN retail stores used a solution for store inventory management that required a lot of work and that was very time consuming. Every time an inventory procedure needed to be performed, someone from the head office would have to bring a laptop with a specific integrated application to each store, along with another terminal for wireless data transfer. These devices needed to be set up for use in the specific store, and the inventory process could finally begin.

Labeling Solutions for Oil Change and Automotive Applications

The simple step of applying oil change reminder labels carries real value for the automotive service establishment and the customer. These labels provide a subtle but persistent notice to the customer of the next service date, helping ensure the vehicle remains in optimal condition. They also remind a satisfied customer where they last received service, increasing the likelihood of return business.

While an enclosed automobile may seem like a relatively benign environment, these labels are subjected to significant environmental rigors. High exposure to ultraviolet radiation can attack labels and adhesive, causing adhesives to harden and leave residue, or causing the label to break apart and delaminate rather than removing in one piece. Temperatures inside a parked car in the summer can quickly reach 140°F, effectively baking the label facesheet and adhesive. During winter, windshields repeatedly cycle between freezing temperatures and heated defrost cycles.

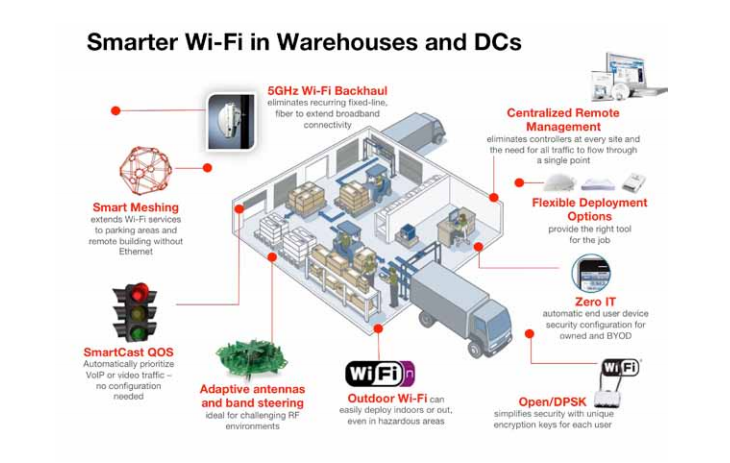

Intermec and Ruckus: Warehousing and Distribution Solutions

Modern supply chains must meet ever higher customer service level requirements while also constantly reducing costs. Intermec and Ruckus Wireless combine the leading workflow performance company with simply better wireless connectivity to enable more efficient and high performance warehouse and distribution centers (DCs).

Modern supply chains must meet ever higher customer service level requirements while also constantly reducing costs. Intermec and Ruckus Wireless combine the leading workflow performance company with simply better wireless connectivity to enable more efficient and high performance warehouse and distribution centers (DCs).

Intermec designs and builds the automated information and data capture (AIDC) industry’s most complete lineup of rugged, reliable and versatile equipment. Its bar code scanners, rugged computers and VoCollect data collection systems are deployed globally by leading warehouse, DC, 3GL and other enterprises that rely on accurate and timely data to track, manage and move products.

5 Ways To Improve Security In Your Point-of-Sale System

Many business owners think that meeting the basic requirements of the Payment Card Industry Data Security Standard (PCI DSS) protocols will keep their point-of-sale systems from being hacked. But here’s the truth: hacking into retailer POS systems is a recurring problem worldwide, even for retailers who meet PCI DSS standards.

Many business owners think that meeting the basic requirements of the Payment Card Industry Data Security Standard (PCI DSS) protocols will keep their point-of-sale systems from being hacked. But here’s the truth: hacking into retailer POS systems is a recurring problem worldwide, even for retailers who meet PCI DSS standards.

In just the last couple of years, several high-profile cases have received media coverage:

- In late 2011, a scheme was discovered that involved hackers from Romania stealing credit card data from hundreds of POS systems, including those from 150 Subway franchises. More than 146,000 cards were compromised, and losses have been estimated at up to $10 million.

- In September 2012, hackers got into POS systems in 63 Barnes & Noble stores in nine states. The company removed POS card readers from all its stores while the incident was investigated.

- In December 2012, an Israeli security firm found a strain of malware infecting hundreds of POS systems in 40 countries. By injecting malware into a system’s iexplore.exe file on Windows servers, the malware hijacked data that could be used for cloning credit cards.

Countless other cases of POS “hacking†come from insiders: your employees. Keeping on top of POS security is essential for every business. Here are 5 ways to improve your POS security.

The Retail Point of Sale Goes Mobile

Mobile point-of-sale payment terminals have experienced explosive growth over the past year. Unlike a traditional point-of-sale terminal, a mobile terminal communicates wirelessly when processing payment cards. There are different types of solutions in the market, but one popular type is an application within a mobile device, like a smartphone or tablet, that uses a hardware attachment to swipe payment cards.Merchants who use these solutions should remember to comply with both existing and evolving legal and card association requirements, particularly as other new payment acceptance solutions, such as integrated chip (IC) and near field communication (NFC) point-of-sale terminals, are adopted widely.

Mobile point-of-sale payment terminals have experienced explosive growth over the past year. Unlike a traditional point-of-sale terminal, a mobile terminal communicates wirelessly when processing payment cards. There are different types of solutions in the market, but one popular type is an application within a mobile device, like a smartphone or tablet, that uses a hardware attachment to swipe payment cards.Merchants who use these solutions should remember to comply with both existing and evolving legal and card association requirements, particularly as other new payment acceptance solutions, such as integrated chip (IC) and near field communication (NFC) point-of-sale terminals, are adopted widely.

Powering Your Printer: What You Need to Know About Lithium-Ion Batteries

Datamax-O’Neil printers are powered by lithium-ion batteries. Lithium-ion is the fastest growing battery chemistry type in the world. In less than two decades, it has progressed from the research and development domain to more widespread use, to the point that they are rapidly becoming the world’s most popular portable secondary battery chemistry. They’re the battery of choice in everything from cell phones and digital cameras to printers and portable PCs and tablets. Lithium-ion batteries are a family of rechargeable batteries in which lithium ions move from the negative electrode to the positive electrode when discharging, and in the opposite direction when charging. They have been referred to as “rocking chair batteries†because of the back-and-forth ionic action during charge and discharge.

Datamax-O’Neil printers are powered by lithium-ion batteries. Lithium-ion is the fastest growing battery chemistry type in the world. In less than two decades, it has progressed from the research and development domain to more widespread use, to the point that they are rapidly becoming the world’s most popular portable secondary battery chemistry. They’re the battery of choice in everything from cell phones and digital cameras to printers and portable PCs and tablets. Lithium-ion batteries are a family of rechargeable batteries in which lithium ions move from the negative electrode to the positive electrode when discharging, and in the opposite direction when charging. They have been referred to as “rocking chair batteries†because of the back-and-forth ionic action during charge and discharge.

Chemistry, performance, cost, and safety characteristics vary across lithium-ion battery types. Unlike disposable lithium primary batteries, lithium-ion electrochemical cells use an intercalated lithium compound as the electrode material instead of metallic lithium. The positive electrode material is typically a metal oxide with a layered structure, such as lithium cobalt oxide (LiCoO2), or a material with a tunneled structure, such as lithium manganese oxide (LiMn2O4), on a current collector of aluminum foil. The negative electrode material is typically a graphitic carbon (also a layered material) on a copper current collector. In the charge/discharge process, lithium ions are inserted or extracted from interstitial space between atomic layers within the active materials.

Continue reading »

Direct to Card vs. Retransfer Print Technology

Direct-to-Card (DTC) printing is the most common technology used by desktop card printer/encoders to transfer images directly onto a plastic ID card. DTC technology prints images by heating a print ribbon beneath a thermal printhead, resulting in the transfer of color from the ribbon to a blank card. With DTC printing, images have sharp edges, deep blacks and a full spectrum of colors. This printing method does not provide full card coverage as a small white border will be at the edges of the card. All major manufacturers produce DTC ID card Printers, with some of most popular models being Zebra ZXP Series 3, Datacard SD360, Fargo DTC1000, and Evolis Primacy.

Direct-to-Card (DTC) printing is the most common technology used by desktop card printer/encoders to transfer images directly onto a plastic ID card. DTC technology prints images by heating a print ribbon beneath a thermal printhead, resulting in the transfer of color from the ribbon to a blank card. With DTC printing, images have sharp edges, deep blacks and a full spectrum of colors. This printing method does not provide full card coverage as a small white border will be at the edges of the card. All major manufacturers produce DTC ID card Printers, with some of most popular models being Zebra ZXP Series 3, Datacard SD360, Fargo DTC1000, and Evolis Primacy.

Retransfer printing is a two-step process that transfers your image to a retransfer film before applying    it to the card. First, the image is printed in reverse directly onto a clear layer of film. Next, the printhead heats up and bonds the imaged film    to the card’s surface by applying heat and pressure. The two step retransfer process creates a true edge to edge (100% card coverage) high quality image on PVC cards and other card types. High end models using this technology include Zebra ZXP Series 8 and Fargo HDP5000. Remember, when using a retransfer printer; don’t forget to add the retransfer film with your ribbon.

For help finding the right  ID Card Printer for your business, contact us at Barcodes Inc.

Why Use RFID Technology for Baggage Handling?

Most airlines struggle day to day with a variety of issues related to survival—issues such as unpredictable fuel costs, uncertain global economies, and tight finances. To combat these challenges, airlines continuously seek to better their operations, and RFID technology is at the forefront of process improvement.

RFID technology can aid and assist in multiple areas to reduce costs and increase operating revenue through improved asset visibility, consumable inventory management, food and beverage delivery management, retail item inventory, sales management, and baggage handling efficiency. This white paper addresses baggage handling specificaly.

Estimates by the International Air Transport Association (IATA) put mishandled baggage costs at approximately $US 2.5 billion for 2009 alone-equivalent to the cost of nearly 50 Boeing 737-600s. This industry problem spans cities, regions and continents. While many assume full participation by all parties is necessary to completely rectify the problem, RFID-enabled baggage tagging efforts already in place show that local or regional implementation of RFID on baggage can have significant benefit, resulting in improved service, substantial cost reductions or savings, and increased customer satisfaction.

Optimize Your Wireless Facility

The top 3 reasons to implement mobile workstations

The top 3 reasons to implement mobile workstations

Thanks to wireless technology, mobile powered workstations (MPWs) are opening up new frontiers of efficiency and productivity. These workstations with integrated power supplies can maneuver computers, printers, scales, barcode scanners, etc., to wherever they are needed. For some facilities, multiple MPWs can bring about a “system solution†— a whole new way of doing business. Capitalizing on the benefits of auto-ID technologies, they integrate the facility’s software with devices on the workstations to establish mobile on-demand label printing stations, mobile shipping/receiving stations, and so on.

Continue reading »

Understanding the Value of Genuine Printer Supplies

Before purchasing supplies, buyers would do well to remember the words of Warren Buffett, a man who knows a little about buying smartly: “price is what you pay. Value is what you get.†The point is simple: it’s not the initial purchase price that ultimately matters, but rather the value delivered by the purchase. This is particularly true when it comes to printer supplies.

Before purchasing supplies, buyers would do well to remember the words of Warren Buffett, a man who knows a little about buying smartly: “price is what you pay. Value is what you get.†The point is simple: it’s not the initial purchase price that ultimately matters, but rather the value delivered by the purchase. This is particularly true when it comes to printer supplies.

Genuine printer supplies are designed by OEM engineers and qualified with the printer itself as part of the research and product development process. They are developed to precise specifications, so that they perform with the printer at a consistently high level, time and time again.

Only genuine supplies:

- Are engineered in conjunction with the printer for superior quality, performance, and reliability.

- Fully protect your hardware investment.

- Keep warranties beyond reproach.

- Benefit from an OEM’s years of operational experience in the market, and with specific applications.

- Mitigate risk of downtime due to printer failure.

Genuine supplies typically bear the imprint or endorsement of the OEM clearly on the packaging. Consulting the OEM or a recognized OEM channel partner is a sure way of verifying whether the supply you have in hand is genuine.