POS at the LPGA

A Small Business with History

For over 27 years, The Wegmans Rochester LPGA has been one of the most popular stops on the LPGA tour. It combines the world’s best golfers, the most enthusiastic crowds and many eager volunteers that join to raise funds for special causes. Disabled Children of Monroe County (DCMC), benefiting Camp Haccamo and the Sunshine Campus, uses the Wegmans Rochester LPGA as their main fund raising event. DCMC operates a store front that sells thousands of hats, shirts, shoes, and umbrellas during the week long event. The success of the event for DCMC increases every year, and the importance of correctly stocking, monitoring and reporting sales in such a short time frame increases each year as well. With this event being the main fund raiser for DCMC, “we just can’t have anything go wrong during the week†says Tim Groth, head of technology for Disabled Children of Monroe County.

The Technological Problem

“Our prior DOS based system was brutal,†states Tim Groth. “It was so difficult to use that we ended up with inaccurate data of what was sold. To add to the problem, the final inventory count must be completed before the vendors pick up their merchandise within hours after the tournament ends. The sales staff just could not keep up. By the end of the tournament they had no idea what they had sold,†Groth adds. It was obvious that help was needed in four main problem areas. First, DCMC needed a system that provided accurate inventory control and monitoring of shrinkage. Second, the system must be easy to implement and use, especially since the staff had little computer training and, in fact, were fearful of using new technology. Third, the system had to provide for quick and easy check out since there were a large number of transactions that were to be performed throughout the day. Fourth, the results had to be fast since this operation begins and ends in one week’s time! The challenge was to make the sales run as smooth as the green!

Improve Truck Freight Carrier Productivity and Cost-Effectiveness with Mobility Technology

The Case for Automating Freight Logistics

In today’s tough business conditions, over-the-road freight carriers are looking for ways to increase productivity, decrease operating expenses, and retain customers. The cold truth is that unpredictable fuel costs, rising labor rates, and other expenses continue to whittle away at freight trucking profit margins. Just as challenging, truck freight customers demand supply chain management solutions that offer reverse logistics and forward/backward traceability.

As many businesses have already discovered, mobility technology delivers exceptional benefits to a wide range of operations. Handheld computers, networking, and mobile thermal printers are proven productivity enhancers. When deployed to truck freight carriers, drivers could quickly enter information into networked handheld computers, scan labels, or tag shipments with bar code or radio frequency identification (RFID) labels. In fact, personnel throughout a trucking enterprise could benefit from instant access to accurate information—while in the office, at the customer location, or on the road.

This white paper discusses key considerations when selecting mobility solutions, and unveils how mobilityenabled operations can improve freight trucking efficiency, reduce operating expenses, and boost customer satisfaction.

The Business Value of Mobility Technology

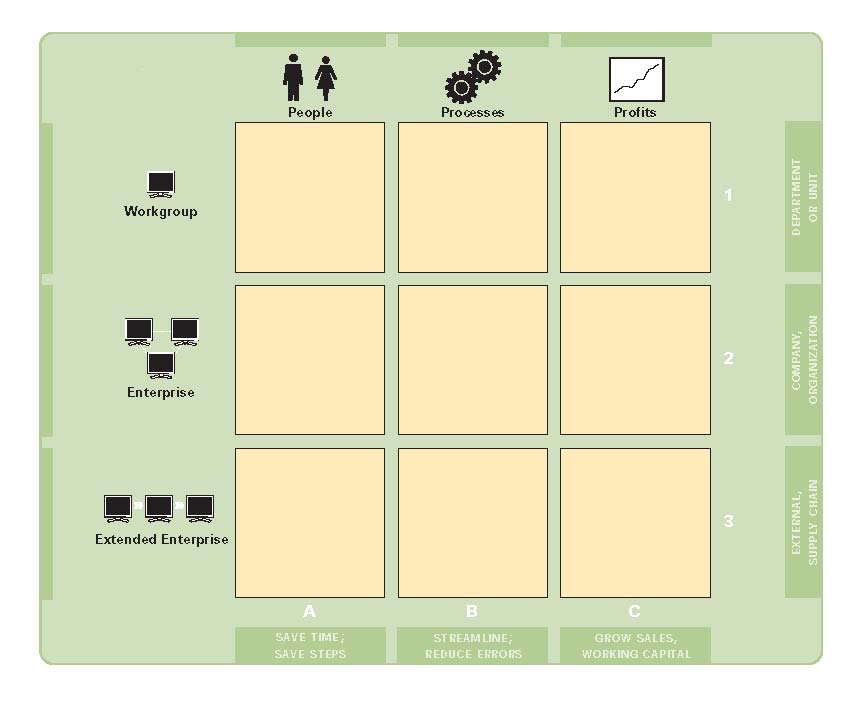

To help identify, classify, and categorize the benefits of mobility technology across a trucking organization, Zebra developed the Zebra Business Value Map. The map relates how mobile computing and printing applications affect people, processes, and profits.

Socket Barcode Scanners Help Humanitarian Groups

By MICHELLE MAN

When you think of adopters of mobile technology, charities may not immediately come to mind, but Socket is seeing a rising number of international humanitarian organizations that deploy our mobile solutions. Some government agencies in the U.S. have also begun using Socket devices in their international relief work.

Businesses in healthcare, hospitality, and other industries usually choose to implement mobile technology as a way to eliminate inefficient paper-based processes, and non-governmental organizations (NGOs) are no different. Humanitarian organizations typically need to collect a lot of data from beneficiaries to assess people’s needs, measure the effectiveness of programs, and ensure the fairness of aid distribution.

Most NGOs generate high volumes of paperwork by collecting data in handwritten forms, which clerks need to transcribe into a spreadsheet or database. Adopting mobile technology enables organizations to spend less time in administrative paperwork, thus allowing them to serve more people and/or improve the quality of aid while also improving accountability to donors, board members, and other parties. Many NGOs are also involved in research studies or complex logistical operations which greatly benefit from mobile computing and data collection technology.

The Task Force for Global Health, based in Decatur, Georgia, uses Socket bluetooth barcode scanners in its program to eradicate lymphatic filariasis (also known as elephantiasis), a parasitic, disfiguring disease that afflicts more than 120 million people worldwide and is a leading cause of permanent and long-term disability in many tropical countries.

Health workers use Socket barcode scanners with GPS receivers and PDAs or laptop computers to track mosquito specimens as well as to scan wristbands and blood/urine samples while visiting households, schools or other sites within a community.

CognitiveTPG Printer & Labels Help Skiers Race Through the Rental Process at Copper Mountain

Challenge

Copper Mountain Resort needed a system to effectively manage its rental equipment inventory between five store locations and to expedite the rental process for its skiers and boarders.

Scenario

Copper Mountain Resort was using an inefficient system to track and manage its inventory of ski rental equipment between each of the five different rental locations. According to Gary Deetz, Warehouse Supervisor, the self made system was faulty and labor intensive. Basically they combined 3 pieces of construction paper to determine store location, shelf location, and product information – the color paper represented the store location.

They needed a system to effectively manage its rental equipment inventory between five stores and to expedite the rental process for its customers. The system had to operate as a stand alone because of limited workspace to include a computer. They also needed to print serialized labels and be able to easily enter the variable information on the spot for the replacement labels. Finally they needed a label that would adhere to the ski, pole, boot, or snowboard without falling off due to the wide array of environments from freezing cold to 70 degrees and very wet conditions.

Solution

CognitiveTPG worked directly with Gary Deetz and his team to find a customized labeling solution to meet the ski resort rental facilities’ requirements. The C Series printer (4†Cxi) was the printer of choice because of its durable construction, LCD user interface menu, and its ability to attach a keyboard/scanner peripheral for a stand alone solution.

Teklynx SENTINEL Drives Global Labeling for Eaton

Eaton Corporation is a global technology leader in electrical components and systems for power quality, distribution and control; hydraulics components, systems and services for industrial and mobile equipment; aerospace fuel, hydraulics and pneumatic systems for commercial and military use; and truck and automotive drivetrain and powertrain systems.

Eaton’s Electrical Sector provides electrical power distribution, power quality systems, industrial automation and control products and services for industrial, utility, commercial, residential and information technology markets. Eaton’s Electrical Sector recently consolidated its worldwide label printing using TEKLYNX® SENTINEL™ to interface with its enterprise systems, and CODESOFT® to manage worldwide formatting and printing.

World’s Largest Furniture Retailer Selects Datalogic Skorpio for Goods Flow

The world’s largest furniture retailer invests in a mobile computing solution with Datalogic Mobile

A world renown furniture retailer has chosen the Datalogic Skorpioâ„¢ to facilitate the handling & tracing of incoming goods. The investment amounts to several thousands of units in the company’s furniture stores around the world.

The Datalogic Skorpioâ„¢ was chosen among its competitors to be used in the company’s new logistics system to handle goods flow. This handheld device offers a Windows operating system, simplified numeric keyboard, excellent ergonomics and extreme ruggedness. In addition, the Datalogic Green Spot assures good read feedback, even in noisy environments. This, along with its service program and management software, Wavelink® Avalanche, guarantees an effective, stable, secure and user-friendly solution in hundreds of stores every day.

The Datalogic Skorpio™ also offers other advantages. The Ethernet 4-slot cradle is the most compact in its class, allowing the mobile computer to be recharged even in the most crowded areas of the warehouse. Thanks to this accessory, the Datalogic Skorpio™ installed in-field can be remotely managed using the Wavelink® Avalanche™ console. The option of using the handheld terminal or the Gun model is also given. The furniture store can choose between these two options, based on its needs for the various store applications.

Intermec Printers Give RH Foster a Fresh Approach to Food Labeling

|

Benefits SummaryRH Foster saved approximately:

|

Convenience store chain eliminates the need for computers, reducing costs and improving worker productivity

Not all the sandwiches RH Foster makes and sells at its chain of Exxon-Mobile convenience stores in Maine are triple-deckers, but labeling them for sale was always a laborious three-step process. Once sandwiches were made and wrapped, the store clerk would apply a preprinted label that identified the sandwiches and its ingredients. The clerk would then grab a labeling gun to set and produce the price label. Finally, the clerk would take a separate labeling gun and set the date to make a “use by” freshness label. That’s three separate steps, and the final product wasn’t even bar coded, resulting in an extra manual step to ring up the sandwiches at the point of sale.

The process also created support requirements at headquarters, where the sandwiches and other food product labels were printed. The foodservice manager would personally print all the labels and either ship or deliver them to retail locations, and was responsible for ensuring each store had enough of the dozens of different product labels that were used. Stores would sometimes run out of preprinted labels and would have to create handwritten ones until a new supply arrived, or end up throwing away labels when ingredients changed or sandwiches were discontinued.

RH Foster wanted to find a smarter way to label its Freshies®- brand products, which are made fresh in each of the company’s 12 retail locations each day. What it found was a smart labeling process that takes advantage of intelligence embedded in an in-store label printer to take time, steps, guesswork and errors out of preparing product labels. RH Foster credits the system for saving at least 130 labor hours per store, per year.

IDG Tools’ Warehouse Relies on Datalogic Kyman

The Swedish company Industriverktyg IDG Tools AB sells tools in a somewhat unique way. Driving around with exhibition buses in Sweden, Norway, Finland, Denmark, Poland and Italy, they display their product range and take orders using the Kymanâ„¢.

The company owns more than 80 buses and have an equal amount of sales people. Their offices and warehouse are situated near the airport in Stockholm, not far from the harbor where they ship their goods to Finland and Poland. Products to their Swedish and Norwegian customers are transported over night, and the orders are delivered to most of the addresses as soon as the day after the order is taken.

IDG Tools AB’s product range is made up almost solely of their own well-known trademark, IDG Tools® (Industrial Development Group). The company has an extensive product range, most of which can be found on exhibition buses.

Datalogic Mobile’s Kyman™ in the warehouse

IDG Tools uses the mobile computer Kymanâ„¢ from Datalogic Mobile in their warehouse and has done so for about a year. The warehouse consists of 4000-4500 items and 6500 places for pallets. Kymanâ„¢ is used to make the picking procedure more effective and simpler. Previously, they used a mobile computer of another brand, which they had to replace since it did not meet their needs. The reason they chose Kymanâ„¢ was due to a recommendation by Sundit – the supplier of their ERP system. IDG Tools gave a list of requirements to Sundit; their main requirements being flexibility, color screen and reliable on-line communication. Sundit then turned to Datalogic Mobile Partner, for the right product. Datalogic Mobile’s Kymanâ„¢ filled these needs. In addition, it is ergonomic, suits the hand, has a sharp screen and is very fast. For all of these reasons, IDG has been very satisfied with their choice.

LXE VX9 Förj Selected by MSC Home Terminal

MSC Home Terminal, the largest container terminal in the port of Antwerp, is a 50/50 joint venture between PSA (Port of Singapore Authorities) and MSC (Mediterranean Shipping Company). Located at the Delwaide dock in Antwerp, it is the most important North European hub for MSC. The terminal’s vital statistics are impressive: a total surface area of 1.6 million m², a quay length extending to almost 3 km, and a total capacity of around 4.3 million TEU. It operates 24/7.

Not surprisingly, MSC Home Terminal is equipped with state-of-the-art handling equipment and controlled by high-performance IT applications. A wireless network was recently implemented. MSC Home Terminal decided to replace the aging narrow band system with a modern Wi-Fi 2.4 and 5 GHz network. At the same time the technical department wanted to launch a proactive maintenance system which would enable maintenance messages to be monitored and eventually sent to the straddle carriers. The messages would inform the drivers to bring their straddle carrier in for a service check. Various selection criteria were drawn up for the vehicle-mounted computers. At the top of the list was undoubtedly the ruggedness of the devices, closely followed by the readability and ergonomics of the screens. All teams of MSC Home Terminal were involved in the selection process, from management to dock workers.

A short list of three suppliers was drawn up and their devices were thoroughly tested by users for ruggedness in a tough industrial environment, ergonomics and screen readability. In addition, the technical department and the IT department looked closely at the technical specifications to ensure the selected device had all the necessary features for end-to-end monitoring of the straddle carriers. Finally, the decision was made for LXE’s VX9 Förj vehicle-mount computers. These are rugged, Windows XP-based mobile PCs with 12.1†touch screen display. Around 120 LXE VX9 Förj computers will be installed on straddle carriers at MSC Home Terminal. The Förj is implemented as a FAT client allowing it to communicate with an independent PLC and the TOS.

Datalogic Falcon 4400 Helps Retailer Reduces Costs

New technology changed Wet Seal’s price markdown and receiving processes from a nightmare to a dream

New technology changed Wet Seal’s price markdown and receiving processes from a nightmare to a dream

New technology changed Wet Seal’s price markdown and receiving processes from a nightmare to a dream. Ron Hunt, Senior Manager of Operations for Wet Seal, a specialty retailer with approximately 400 stores in the United States and Puerto Rico, explained how his company reallocated labor hours being wasted on price markdowns and reduced shrinkage with help from the Datalogic Falcon® 4400 mobile computer.

Before, “We used old scanners. Training was difficult … a nightmare,†he said. “This is a dream … You never have to reprogram it.â€