ICYMI: Next Generation Productivity Gains in the Warehouse with Lydia Voice

In case you missed our webinar today, click on the video and watch Barcodes and EPG discuss how to increase the productivity, accuracy, and employee satisfaction in your distribution center with Lydia voice running on rugged multi-purpose Android devices.

Key takeaways include:

1. Modernize and optimize your warehouse process workflows to better leverage your investment in new Android-based technology

2. Reduce the number of steps in a traditional handheld barcode scanning order picking process to boost productivity by up to 35%

3. Increase productivity with no voice template training that makes new hire employee training seamless

Improving Automation for Manufacturers & Distributors

Oct. 30, 2019 11:00 AM (Central Time U.S and Canada)

Join Barcodes, Smart Label Solutions, and Impinj to learn about key market factors and technologies impacting the landscape of the connected supply chain. Hear how investments in supply chain automation improve visibility to materials, work in process, items in transit; speed up dock door processes; manage valuable RTIs and more.

Key takeaways include:

- Retailers are increasing pressure on manufacturers and distributors to develop smarter supply chains

- Manufacturers and distributors need to provide better visibility of goods and assets in transition

- Efficiency gains enabled by even modest investments in process automation and supply chain transparency drive significant return on investment

By registering, you submit your information to Barcodes, who will use it to communicate with you regarding this event and other services.

Transform Janam’s XT2 Series Touch Computer into an RFID Reader

Turn your touch computer into a handheld RFID reader with the new Janam RFID sled for the XT2 Series! With the high-performance UHF RFID sled for the XT2 series touch computers you can snap it on and turn your mobile device into a RFID reader.

It has been proven that RFID can identify opportunities in a warehouse to enhance day to day operations. Workers can walk through the warehouse with Janam’s XT2 with RFID reader and be able to read multiple tags simultaneously from 22 feet away. That means they can scan an pallet of goods in a few seconds creating greater efficiency and productivity in the workforce.

Using RFID can improve inventory control along with eliminating errors and inaccuracies. RFID allows you to capture real-time inventory data which allows real time visibility of what materials are on the floor immediately in a fraction of the time it takes to capture data through bar code scanning.

- Powerful UHF RFID technology for tag writing and locationing

- Reads EPC Global Gen2 ISO 18000-6C RFID tags

- Own 3350mAh battery to ensure full shift power and eliminate downtime

- Lightest UHF RFID sled in its class

- Able to read a tag from more than 22 feet away

Watch the video below and see how the Janam’s XT2 Series and along with the new RFID sled can bring you more efficiency and visibility in your supply chain.

Contact us if you have any questions into improving your operational efficiency and decrease downtime in your workforce.

Zebra ZT410: The Barcode Printer for Your Warehouse Solution

- Ethernet, USB, and Bluetooth with optional Wi-Fi addition

- Direct and Thermal Transfer Printing

- Handles wide range of media

- Dual USB port for added flexibility

- Intuitive icon-based interface with an optional LCD screen to show any alerts

- Easy media and ribbon loading

- Rugged durability for demanding applications

- Energy Star qualified

- Link-OS Solution

Make the Right Choice for Your Business and Make the Switch Today!

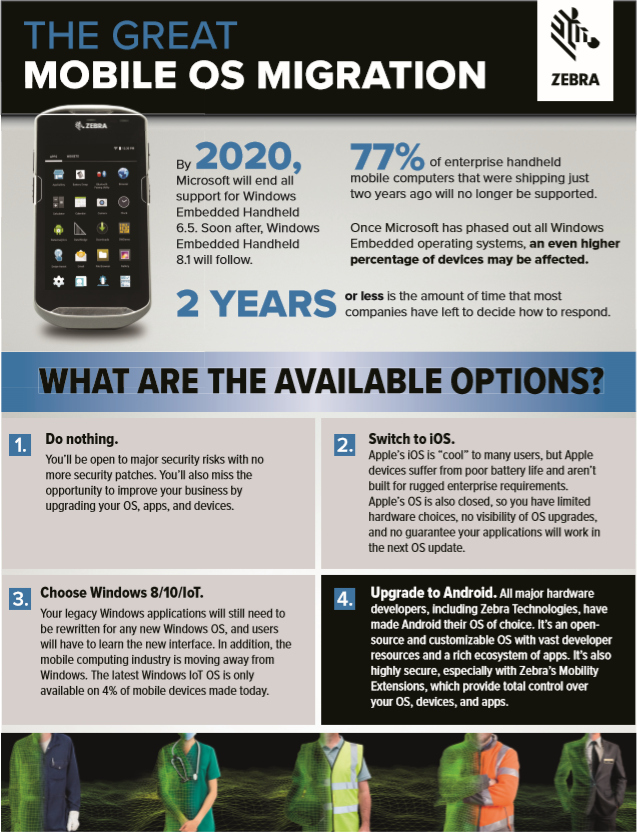

What will you do when Microsoft ends all support for Windows Embedded Handheld 6.5 and 8.1? It is important to take the time and plan out your strategy to ensure a solution before this takes place. Check out your options below and make the right choice for your business! Contact our dedicated account managers and see how we can help you in this process!

Warehouse Efficiency with the Zebra TC8000

Zebra’s TC8000 is the ground-breaking all new warehouse mobile computer designed to deliver revolutionary productivity increases in the warehouse. In fact, on average, it saves 14% per worker versus traditional form factors. It’s like gaining an extra hour of productivity, per worker, per day.

Designed to face the user while scanning, the larger screen eliminates the need to tilt and verify each scan, increasing efficiency on every scan. It’s the only device on the market that simplifies how your workers physically use the device and interact with your warehouse application.

Zebra’s TC8000 Provides Revolutionary Warehouse Productivity Gains

The standard for mobile computers has followed the same general form factor since their inception. Essentially following the original PDT format, mobile computers may have added things like pistol grips but the scanner axis has been perpendicular to the display. With every scan you are always in a sequence of tilt-to-read the screen and tilt-to-scan motion. Though it may not seem significant, every tilt takes time and fatigues a user’s wrist.

The standard for mobile computers has followed the same general form factor since their inception. Essentially following the original PDT format, mobile computers may have added things like pistol grips but the scanner axis has been perpendicular to the display. With every scan you are always in a sequence of tilt-to-read the screen and tilt-to-scan motion. Though it may not seem significant, every tilt takes time and fatigues a user’s wrist.

Zebra is the only manufacturer to properly address the issue of wasted motion and needless fatigue while researching the mechanics of warehouse workflow. The TC8000’s unique design is the fruit of this detailed investigation into improving the worker experience and their efficiency.

The TC8000 minimizes motion with an innovative scan angle that eliminates the thousands of times your workers need to tilt their device to see the screen. With the TC8000 you can always scan and view the screen at the same time. It’s also an amazing 33 percent lighter than the traditional device to help minimize fatigue.

With a large touchscreen, the user experience is similar to a smartphone that everyone is familiar with which makes the TC8000 very easy to integrate into any environment.

You may ask how much difference these differences actually make? On average, the TC8000 improves productivity by 14% per worker versus the traditional form factors. And it’s the only device on the market that simplifies it all, how your workers physically use the device and interact with your warehouse application.

Key Features

- Superior ergonomics for superior productivity and worker comfort

- Rugged and ready for your warehouse

- Enterprise-class android kitkat

- Triple-shift battery power and unsurpassed battery management

- Capture multiple barcodes and entire forms with a single scan with SimulScan

- Advanced touchscreen technology for flexible data input

Zebra’s New TC8000 Mobile Computer Revolutionizes Warehouse Operations

Zebra has recently introduced the TC8000 enterprise mobile computer, a landmark innovation in warehousing technology that will drive significant gains in productivity and decrease worker fatigue. The ergonomic, lightweight TC8000 mobile computer offers an innovative design that reduces muscle effort by eliminating the need for “tilt and verify” motions warehouse workers repeatedly conduct with traditional devices. Shaving seconds off each repetitive motion saves one hour per worker per shift, increasing productivity by an average of 14 percent based on workflow.

Zebra has recently introduced the TC8000 enterprise mobile computer, a landmark innovation in warehousing technology that will drive significant gains in productivity and decrease worker fatigue. The ergonomic, lightweight TC8000 mobile computer offers an innovative design that reduces muscle effort by eliminating the need for “tilt and verify” motions warehouse workers repeatedly conduct with traditional devices. Shaving seconds off each repetitive motion saves one hour per worker per shift, increasing productivity by an average of 14 percent based on workflow.

Zebra worked with users around the globe to completely re-think, re-design and re-engineer industrial mobile computers based on deep research and human factors analysis. The result is the new rugged Android-based TC8000 mobile computer, 33 percent lighter than traditional mobile computers and requiring less muscle effort and reduced wrist motion to help increase the productivity of warehouse workers. It also reduces training time and makes data entry significantly faster and more accurate in challenging industrial settings.

When Time is Money – It Adds Up

When choosing a mobile computer or barcode scanner, one of the last things on anybody’s mind is what kind of battery I should buy with my device. Even worse, sellers fail to explain how the battery alone can save a company on time, money and productivity.

When choosing a mobile computer or barcode scanner, one of the last things on anybody’s mind is what kind of battery I should buy with my device. Even worse, sellers fail to explain how the battery alone can save a company on time, money and productivity.

Research shows that companies lose at least 20 minutes of productivity every time a battery is changed mid-shift. Here’s an example of what device downtime can cost:

- 500 devices in operation

- 500 devices x 1 battery failure each = 500 mid-shift failures per day

- 500 mid-shift failures x 20 minutes each = 167 hours lost each day

- 167 hours/day x $9.00/hour = $1,503.00 per day

- $1,503.00 x 360 days = $541,080 PER YEAR in lost productivity

Don’t take chances with your batteries – IPT Productivity+ Series batteries run 15% – 20% longer and guarantee 100% compatibility with OEM devices including Symbol, Zebra, Motorola, Honeywell, Intermec, LXE, Datamax-O’Neil and Vocollect.