Wireless Printing Delivers Efficiency and Cost Savings in Retail

Wireless bar code and radio frequency identification (RFID) label printing is widely recognized by major retailers globally as an essential technology for enhancing store operations. The ability to print real-time information in the aisle, on demand, saves time, effort, and money—creating competitive advantages.

Once a retailer deploys a wireless network, the benefits of in-store wireless printing become self-evident. Employees can generate tagging labels, coupons, receipts, or tickets on demand at the point of need, and place products on promotion at a moment’s notice. Store associates can complete shelf price audits and re-labeling tasks within a short time period. Store managers can be more confident of shelf price integrity, resulting in fewer price checks at the register. Checkout clerks can print receipts as part of a mobile point-of-sale or customer line-busting solution. In addition, item-level RFID tagging enables precise inventory management and improves store efficiency.

Wireless printers, especially handheld mobile printers, can help lower total in-store printing expenses, reduce total cost of ownership (TCO), improve labor productivity, boost return on investment (ROI), and increase customer satisfaction. The pages that follow detail the far-ranging benefits of wireless bar code and RFID printing, and present innovative wireless printing solutions from Zebra.

Wireless Printing is Now Mainstream

The cash register, the bar code, and the self-service kiosk all first proved their value in retail stores before becoming mainstream productivity tools. Now, another technology is delivering retailers new cost savings, operational efficiencies, and opportunities to improve customer service: wireless printing of bar code and RFID tags. The characteristics that set wireless printing apart from traditional cabled printer configurations—a smaller footprint, unlimited placement options, improved aesthetics, lower maintenance costs, and improved safety and productivity—are perhaps more valuable to retailers than any other industry.

“Wireless printers” refers to printers in which a radio frequency (RF) or infrared light (IR) interface connects the printer to the network, a controlling PC, a handheld computer, or both. By selectively replacing shelf-label printers, pricing guns, shipping-label printers, receipt printers, coupon stations, and other label-generating equipment with wireless printers, retailers can reduce printing and labeling expenses while improving customer service and floor staff productivity.

Wireless printers come in different sizes and shapes, from full-featured stationary models to small, mobile printers that workers can clip to a belt, carry by hand, or wear on a holster. The wireless interface eliminates the need for cables, eradicating a potential failure point and the subsequent repair or replacement cost, while providing a safer and more space-efficient work area.

How Retailers are Using Wireless Printers

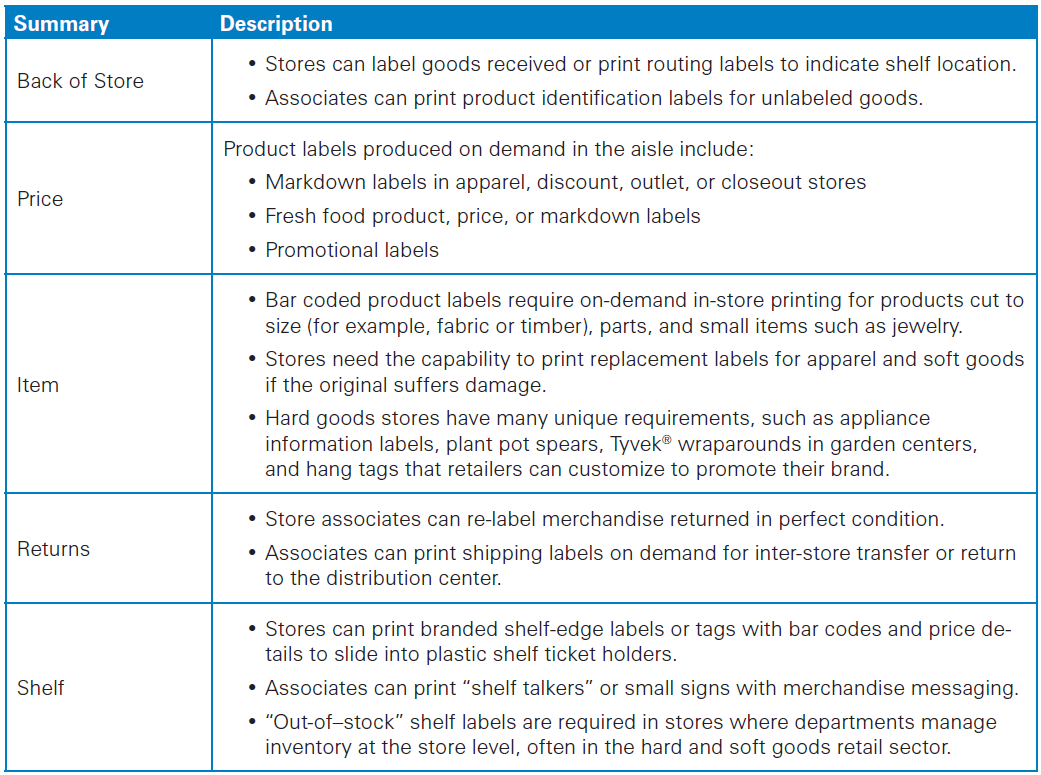

Wherever an item moves, or wherever a business receives or displays products, all present an opportunity for on-demand labeling with real-time price, product, or inventory information. Major U.S. and European retailers depend on wireless printers for on-demand labeling in all aspects of the store, whether it be item or shelf marking, signage, transfers, or returns.

Below are some examples of how leading retailers are using wireless printing technology today to improve operational efficiency and create compelling business advantages. In the section that follows, the discussion drills deeper into typical applications, and the benefits to the enterprise.

Typical Applications and Their Benefits

Retail businesses can benefit from wireless printers everywhere their staff uses bar code labels, RFID tags, coupons, receipts, or tickets. The sections that follow detail specific applications where wireless printing delivers the highest productivity gains and value to the enterprise.

Streamline Shipping and Receiving

Traditionally, a stationary thermal printer was located in the back of the store and dedicated solely to shipping/receiving operations. Now, with wireless mobile printers, the associate can label product at the spot, saving time and reducing labeling errors.

Additionally, whether wireless stationary or wireless mobile printers are used to create shipping and receiving labels, the store saves on rewiring costs if the configuration of the back room changes. Workers can easily move printers and add new printers to the network without incurring the time and expense of rerouting or installing new network cable. Businesses can easily network wireless printers to a host computer located elsewhere in the store, which often eliminates the need for a dedicated PC at the labeling area. In addition, mobile computers can reroute print jobs on demand, further reducing the need to keep a PC in the back room just to store shipping and label format information.

Improve Traceability with Item-Level RFID Tagging

Until recently, most retail RFID use focused on pallet and case-level tracking. With item-level tagging, suppliers and retailers can use RFID tags, affixed to an item’s packaging or the actual item itself, to gain real-time inventory information and significant time savings over standard Universal Product Code (UPC) bar codes. As the retailer receives products, an RFID reader automatically scans each item in the packing material, and updates the retailer’s computer system, which then verifies product type and quantity. Scanners in the store track the item’s purchase, or if the item leaves the store without the shopper paying for it. The enhanced visibility allows a store chain to reduce stock-outs, boost the shopper’s buying experience, and increase sales.

In addition to using tags attached by item manufacturers, retailers can replace damaged tags or add price or markdown tags in-store with wireless stationary RFID printer/encoders located in the back room, or efficiently print and encode tags in the aisle at the point of application with wireless mobile printer/encoders. Mobile printing eliminates the need to walk to a centralized printer/encoder for tags, improving productivity and labeling accuracy.

Item-level tagging enables the retailer to know what is selling, where, and when—powerful metrics that marketing departments can quickly leverage to improve customer loyalty and branding campaigns. In addition, RFID-based Electronic Article Surveillance (EAS) item-level tagging can provide the retailer loss-prevention intelligence regarding what item left the store without being paid for, and when the theft took place.

Ultimately, item-level tagging could allow consumers to shop without money, sales clerks, or even cash registers. The consumer walks into the retailer and finds their items, and the retailer charges the consumer’s bank account automatically. The following list provides a small subset of the applications that item-level RFID tracking makes possible:

-

- Reading tags on garments hanging on a mobile metal rack

-

- Reading tags on items in cases and on pallets going through a dock door portal

-

- Reading tags on apparel at the point of sale

-

- Reading tags on DVDs sitting in adjacent shelf slots in a display

-

- Reading tags on a mixture of consumer items in a plastic tote

The University of Arkansas Information Technology Research Institute recently completed a study to determine the business value of RFID item-level tagging for day-to-day operations in a retail environment. The results demonstrated that overall inventory accuracy improved by more than 27 percent, understock decreased by 21 percent, and overstock decreased by 6 percent.

The study also compared how long it took to count items using RFID versus a bar code reader. With RFID, scanning 10,000 items took two hours; scanning with a bar code reader took 53 hours. This translated into an average of 4,767 counted items per hour with RFID and 209 items per hour using a bar code system, a 96-percent reduction in cycle-counting time.

Simplify Shelf Labeling

Producing shelf price labels and promotional flags with wireless mobile printers, instead of centrally located printers, can save retailers thousands of dollars per store location annually through improved productivity and reduced media costs. Using a mobile printer interfaced wirelessly to a handheld computer or a host computer allows workers to print bar code shelf labels and in-aisle promotional flags at the precise location with accurate information—eliminating trips to the back of the store to pick up printed labels.

Store associates can also use wireless mobile printers to create new shelf and item labels for price changes. Daily or weekly price changes can be loaded into a handheld mobile computer with software that plans the most efficient route for workers to manage the aisles. The mobile printers create new shelf or item labels and wirelessly send a confirmation to the pricing database.

Improve Shelf Price Auditing Accuracy

To realize the importance of accurate shelf pricing, consider the large number of legal challenges currently active. For example, the City of Cleveland litigated against a drug store chain over discrepancies between prices displayed on retail shelves and prices charged at the checkout. Since then, a large number of municipalities also enacted measures to keep a close watch on retailers in their jurisdiction. Retailers, who already struggle to maintain pricing integrity, now have another legal and public relations threat to face.

Fortunately, retailers now have a new tool at their disposal to detect and correct potential pricing errors: wireless shelf price auditing. Store associates can audit shelf price accuracy by using a handheld mobile computer with a bar code or RFID reader to scan the UPC codes of items on the shelves. The scan initiates a price lookup in the same UPC database used to charge items during checkout. If the price displayed on the mobile device differs from the price on the shelf label, the associate can instantly print and place a new, accurate bar code label on the shelf.

Enhance the Shopping Experience with Kiosks

Today’s wireless kiosk solutions help tie communications consumers receive outside the store to their in-store experience. Wirelessly connected kiosk solutions integrate with online couponing sites that provide promotions through text, mobile Web, or Internet on smart phones, driving new consumers into the store with offers that the kiosk validates on the spot.

The ability to link sites that provide promotions to a smart phone, for example, is just one way kiosks are connecting their businesses to on-the-go consumers. Once the consumer is in the store, interactive kiosk solutions equipped with built-in wireless communication allow consumer check-ins and authentication for promotions and codes scanned from mobile phones, loyalty or reward cards, coupons, or manual entry of the code. The kiosk then validates and authorizes the code and prints an authenticated receipt or coupon that the shopper can use at checkout.

Additionally, kiosks with integrated label printers allow shoppers to print the price label on demand. The Commonwealth of Massachusetts amended its retail pricing laws to allow price verification kiosks with label printers as a substitute for individually marking items with a price label. While not all customers will want a label, the law mandates that they must have the ability to print one. By printing labels at the kiosk, shoppers will know how much their items cost without going back to check each shelf label, and there will be fewer discrepancies at the register. Kiosks give consumers the convenience of checking prices or locating items in the store without asking store associates, while giving retailers in Massachusetts and other states considering similar legislation a way to avoid fines.

Boost Customer Satisfaction with Line Busting

Using a mobile point-of-sale (POS) system during busy periods, including holidays and special sales, can reduce line lengths or wait times and improve the customer experience. Adding a lightweight thermal printer to the POS system enables departments to print quality receipts and return labels with printed bar codes and graphics, instead of the low-quality receipts associated with impact printers. Thermal printers are also durable enough for outdoor use at garden centers, building supply stores, and other retailers offering seasonal goods like mulch, flowers, or Christmas trees.

Speed Returns Processing

Wireless printers add convenience and security to returns processing operations, both in the back room and on the retail floor. Using wireless printers in the back room to create shipping labels and inter-store transfer labels delivers all of the benefits discussed in the shipping and receiving section above. In addition, departments can improve security and customer convenience by using wireless mobile printers on the retail floor. If stores use a centralized returns area or customer service counter, thermal printers can create returns slips with quality logos, graphics, and two-dimensional (2-D) bar codes.

Roaming store associates can process returns immediately as customers enter the store, providing convenience for them and security because merchandise does not need to travel throughout the store. Retailers can also accept returns in outdoor areas or even the parking lot, which is a great advantage for bulky or high-volume items. Like mobile POS, mobile returns processing shortens lines before customers run short on patience.

Improve Direct Store Delivery (DSD) Management

Direct store delivery is often very challenging for retailers and vendors. Before the development of the DEX (Direct Exchange) UCS (Universal Communications Standard), a vendor typically would deliver a certain quantity of items, scratch out an invoice for the retail store manager to file away (and hopefully enter into inventory), and deliver a copy of that invoice back to the vendor’s own accounts receivable department for processing. Retailers frequently disputed bills submitted for payment because of pricing discrepancies, or charge-backs for

unauthorized deliveries.

To let retailers capitalize on 802.11b/g wireless networks already installed in many retail stores, Zebra created a solution to help cut DEX usage costs by eliminating the cabling expense. Instead of plugging into a DEX port, the vendor can send the information via a cable to Zebra’s RW series wireless printers. The printer can then communicate the data over the 802.11b/g network back to the store server.

Zebra Printers—Dependable and Flexible

Zebra mobile wireless printers are lightweight, easy to use, and durable, and offer outstanding print quality and graphics previously found only on fixed, stationary printers. Retailers can use wireless mobile printers to produce high-quality bar code labels, RFID tags, receipts, coupons, and tickets using a variety of media. Using wireless for cable replacement improves ergonomics and productivity. Wireless systems are more reliable because there is no chance for printer cables and pin connectors to break.

Many retailers already use wireless handheld computers in their stores for inventory, shelf-price auditing, and other applications. By complementing these devices with a mobile printer, retailers can leverage their initial wireless investment and take advantage of a wide range of cost-reduction opportunities. Zebra printers are available in a variety of designs to meet the needs and preferences of each mobile workforce.

Extensive Wireless Support

Zebra Technologies offers its customers flexibility and security by supporting all the leading wireless networks used in retail. Stationary printers with wireless print servers can easily be attached to a wireless network. Printers from Zebra support a wide range of wireless options through modular hardware, enabling anywhere, anytime communications. Retailers can choose the wireless connectivity that best suits their needs, including medium-range 802.11, short-range Bluetooth, or IrDA (line of sight infrared). Zebra printers support multiple wireless security and encryption standards, so businesses can feel confident that their networks and critical data remain secure.

Longer Battery Life—Increased Uptime

How the mobile printer manages its power supply impacts overall battery life and application effectiveness. Battery life varies widely based printer usage. Print volume, label size, the amount of wireless activity, and other factors all affect how long batteries last before recharge or replacement. Nickel metal-hydride (NiMH) batteries have a higher initial cost than nickel cadmium (NiCAD) products, but have less performance degradation over time, are more efficient at holding their charge, and have a longer life span. Lithium-ion (Li-Ion) cells offer the highest power-to-volume and power-to-weight ratio of the three.

The Zebra QLn mobile printer family leverages innovative Power Smart Print Technology to deliver faster processing and throughput with lower power drain. For mobile workers on the go, the new battery technology means better quality printing and more uptime on the job. Zebra’s “smart battery” technology displays charge and overall battery health, reducing downtime typically found in standard battery technologies that run out of charge before the workday is done.

Eliminate Cable Cost Overhead

With wireless networking, printer expenses drop since the use of cables for communication between mobile printers and handheld terminals adds to the printer’s TCO over time. A survey of retailer store associates revealed that an average of two minutes per day, per terminal/printer was devoted to troubleshooting cable-related problems. Across a 100-store chain, this would translate into thousands of hours of “non-productive” labor every year that wireless printing would eliminate.

Retailers can also save substantial direct capital expenses by going wireless. Printer/terminal cables can run as high as $50 to $60 each. As the cables age, stores replace them at a rate of two cables per terminal, per year, on average. By switching to wireless printing, a 100-store chain using five mobile printer/terminals per store would save $60,000 annually.

Wireless Printers and Retailers—A Perfect Match

Wireless printing provides increased efficiency and flexibility that help lower operational costs and improve customer satisfaction. In most applications, retailers can see an almost immediate return on investment after implementing wireless printing solutions. Wireless-enabled mobile printing is a powerful combination that allows store associates to spend more time helping shoppers and improving customer loyalty. Bar code and RFID printing—from the retail supply chain to the store aisle—improves productivity, enhances product visibility, and boosts the customer experience.