Weighing and Scanning Large, Irregular-Shaped Items? Try the CubiScan 325

Measuring large quantities of spatulas, machinery components, bolts, and apparel can be a challenge for order pickers and warehouse operators. Non-uniform shapes are hard to measure, and high turnover and rotating shift workers means you never get consistent measurements on your ever-changing library of SKUs. Inconsistency in measurement and process leads to unreliable master data, and inefficient downstream processes. Enter the Cubiscan 325, an automated object dimensioner and scale.

If you want to reduce inefficiencies in your supply chain, this machine is an excellent starting point. Master data collection, storage, carton selection, and pick and pack are much easier processes with the Cubiscan.

Accurate, Efficient Dimensioning with the CubiScan 325

The Cubiscan 325 eliminates the need for manual measuring and weighing by automating the dimensioning process, reducing physical strain on employees, limiting manual data entry errors, boosting overall productivity, and improving cost savings across every operational area.

Key Features of the CubiScan 325

Dimensional Accuracy

The Cubiscan 325 uses infrared light to collect product dimensions down to 1mm, ensuring that accurate data is used for inventory and shipping calculations. This reduces the possibility of costly mistakes in shipping and order fulfillment. This large format, automated imager and dimensioner accommodates SKUs up to 36′′ long, 24′′ wide, and 24” tall.

Cost Savings

With accurate product dimensions, shipping costs can be reduced. Accurate master data is fed to WMS and cartonization softwares to help packers pick the right box for an order. In turn, shippers ship less air and more product, reducing the overuse of packing materials to fill excess “air” in the box. This also reduces their overall parcel spend, because efficiently packed orders means shippers aren’t paying to ship extra air. The savings are particularly impactful for high-volume shippers, where efficiencies and proper packing are spread across thousands of shipments. Invest in a dimensioner, because the long-term cost savings from reduced errors, improved efficiency, and optimized storage are significant.

Inventory Accuracy & Enhanced Order Picking

Accurate product dimensions aid in inventory tracking. This is especially useful in industries with a large number of SKUs, where inventory discrepancies can be expensive and time-consuming to resolve. The Cubiscan 325 also integrates with existing order picking systems, assisting employees in efficiently and accurately selecting the right products, reducing order fulfillment errors.

Seamless Integration with WMS & ERP

The Cubiscan 325 can be seamlessly integrated with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) software, reducing manual data entry errors, streamlining the flow of information, and improving overall database quality for irregular and complex SKUs in the warehouse.

Improved Warehouse Space Utilization

By accurately measuring product sizes, operations managers can optimize warehouse storage space and layout, reducing wasted space and improving overall efficiency.

Data Analytics

The Cubiscan 325 data can be used to perform analytics and gain insights into product trends, demand forecasting, and process optimization.

Ensured Compliance

For industries with specific regulations governing accurate product measurement and labeling, the Cubiscan 325 assists operations managers in ensuring regulatory compliance as well.

Faster Order Processing

Order processing becomes faster and more efficient with the Cubiscan 325’s automation capabilities, which can lead to faster order fulfillment and happier customers.

For a detailed list of capabilities, download the Cubiscan 325 spec sheet.

Watch: The CubiScan 325 in Action

Incorporating a CubiScan 325 into your workflow can help streamline operations, reduce costs, and improve overall productivity and accuracy, making it a valuable addition for operations managers across a wide range of industries. See how it works below.

Smarter Dimensioning Today

We’ve covered how useful the CubiScan 325 is. It’s also just plain magical to see in action. Contact us for your dimensioning needs today – we’ll deliver a custom solution for you.

The Next Dimension: A Closer Look at the CubiScan 150 Scale

The CubiScan 150 Scale improves inventory management, increases supply chain efficiency, and increases overall production, making it a great tool for firms looking to simplify operations and save money.

How Does the CubiScan 150 Scale Work?

The CubiScan 150 uses laser technology to scan and record the length, width, height, and weight of an object that is put on its measuring base.

Once object data is collected, it can be added to inventory management systems and shipping software to give exact and consistent information about how big and heavy goods are. To understand the best way to pack and ship items, ensure items follow shipping rules, and avoid common shipping mistakes, a CubiScan dimensioning system is an invaluable solution.

In addition, the CubiScan 150 can buffer thousands of data records, link to barcode scanning equipment, label printing devices, and interact directly (in batch or real-time mode) with your manifesting or warehouse management system.

The CubiScan 150 Scale has various advantages for a multi-use dimensioning system.

- It’s compact in size.

- It correctly measures and weighs things using modern volumetric scanning technology, delivering perfect measurements for packaging and shipping calculations.

- It saves valuable warehouse space, lowers shipping costs, and decreases mistakes.

- It has a user-friendly interface.

- It’s simple to integrate with current systems.

Reasons to Consider a CubiScan 150

The CubiScan 150 is a tough piece of equipment, with a maximum measuring range of 39 x 40 x 48 inches (100 x 100 x 120 cm) and a net weight capacity of 150 lbs (70 kg).

The scale is accurate, with a measurement precision of 0.1 inch (0.2 cm) and a weight resolution of 0.05 pound (20 gram).

The CubiScan 150 is equipped with lockable casters, allowing it to be used in a fixed position or swiftly relocated and redeployed as needed.

Each device has a USB connector, two active serial communication ports, one serial printer port, and an Ethernet port for network connectivity and data transfer.

For a full list of capabilities, download the CubiScan 150 spec sheet.

See the CubiScan 150 in Action

Learn how the CubiScan 150 may help you minimize costly charge-backs and improve the most crucial component of your business: your bottom line.

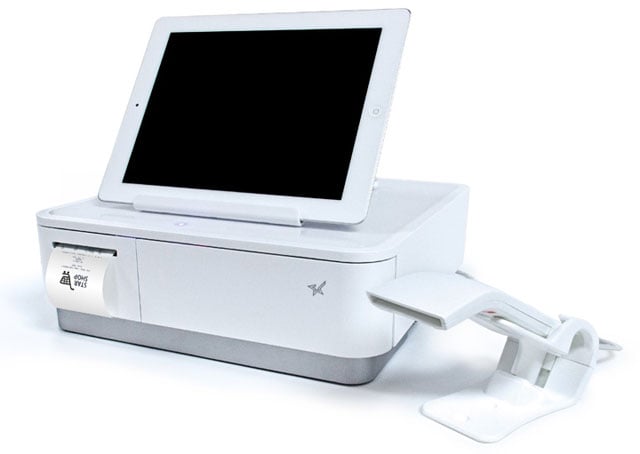

New Peripheral Support for Star’s mPOP System

Star has announced a new series of peripherals for their comprehensive mPOP system. Star’s mPOP now supports an optional scale, 2D barcode scanner, customer display, and external cash drawer. With these added peripherals, retailers and restaurateurs can now transform their mPOP into a complete point of sale hub to accept more versatile transactions in higher volume.

has announced a new series of peripherals for their comprehensive mPOP system. Star’s mPOP now supports an optional scale, 2D barcode scanner, customer display, and external cash drawer. With these added peripherals, retailers and restaurateurs can now transform their mPOP into a complete point of sale hub to accept more versatile transactions in higher volume.

Star has integrated support for three Detecto APS scales. The APS scales supported are offered for varied use cases. The APS10 (max. 15 kg) is ideal for candy shops, delis, frozen yogurt shops, etc., where the APS20 (max. 15 kg) is better for larger items like bags of fruit and vegetables at a farmer’s market or grocery store. The APS12 (max. 160 oz.) is best in similar environments as the APS10, or any other location than prefers to measure in ounces.

Star has integrated a 2D barcode scanner for the mPOP. Now, users have the option of choosing between the Star 1D scanner and the new 2D scanner. The 2D barcode reader will be beneficial to accept coupons in the form of QR code, or access item information. In addition to 2D barcode scanner support, Star has designed a two-line, blue backlit customer display with up to 20 characters per line. With this support, the retailer can not only show the customer their transaction price, but they can also add advertising messages for when the mPOP is not being used.

Lastly, Star added a cash drawer connection port (DK port) to the mPOP to support an extra cash drawer. This is ideal for users who need a point of sale system with a small footprint, but still have a higher cash flow, such as a bar or deli.

Datalogic Revolutionizes POS Barcode Scanning with the Magellan 9800i

Datalogic has announced their new and revolutionary Magellan 9800i retail point of sale barcode scanner. The sleek, new Magellan 9800i is the result of over 40 years of engineering innovation and sets a new standard of excellence.

Datalogic has announced their new and revolutionary Magellan 9800i retail point of sale barcode scanner. The sleek, new Magellan 9800i is the result of over 40 years of engineering innovation and sets a new standard of excellence.

Digital imaging technology quickly reads 1D and 2D bar codes while giving the Magellan 9800i a 20% increased platter area.

The optional top down reader increases the scan volume and provides a customer facing mobile device reader. Datalogic patented All-Weighs platter and ScaleSentry technology assures the accurate capture of large and bulk weighed items.