9 Reasons Why You Can’t Afford Not to Invest in Mobile Power Solutions for Your Distribution Center

1. Solutions for Every Scenario

1. Solutions for Every Scenario

You can’t afford not to implement solutions for your warehouse challenges. Whatever the particular challenge is at your nationwide fulfillment centers, your 1 million square foot warehouse, your 24/7 distribution center, or your manufacturing plant, mobile power solutions are available to:

- Streamline your processes

- Help your employees accomplish the most each shift

- Ensure exceptional, on-time customer service

No matter what your facility’s particular needs may be, there are viable solutions available via the implementation of customized power workstations. Whether your particular situation is similar to those Newcastle Systems customers experienced, or it’s a one-of-a-kind challenge, there is an affordable, doable, and easy solution.

The following scenarios depict companies which are ‘stuck’ or are growing, and the solutions they’ve implemented:

Scenario #1:

For years, workers in the receiving department at Amazon.com dealt with their usual challenges with incoming product discrepancies, including quantities that didn’t match the packing slip or purchase order, and countless products without the necessary barcode label. Hours were wasted each shift as the receiving personnel spent a huge portion of their day walking back and forth to Amazon’s stationary label printers to produce new barcode labels and their stationary computers to research the discrepancies.

Solution #1:

Amazon invested in 800 “Mobile Problem Solve Carts†~ the PP25 Stand Alone Power Package. This solution enabled the receiving personnel employed at Amazon’s 20 different fulfillment centers across the country to glide their workstations easily over to the products with the discrepancies and/ or missing barcode labels.

Fabulous Fact: Amazon’s PP25 Stand-Alone Power Package came with a 200 AH battery system capable of powering a laptop, Zebra 2844 label printer, and scanner for 24 to 36 hours at a time!

Scenario #2:

Deli workers at each of the 80 locations of a members-only wholesale cash and carry food service supplier had to move huge and heavy pallets of sliced meat and cheese physically over to a stationary scale and printer. Once the deli workers weighed the food products, the items then had to be repackaged, weighed again, and labeled with a price and date code. Even though time and productivity were affected every day, bottlenecks in the aisle ways became the norm.

Solution #2:

The national wholesaler of commercial food, equipment, and supplies invested in the PP12 Portable Power Package at each of its 80 locations ~ enabling the wholesaler’s deli workers to utilize a fully-functional mobile weigh and label station. Instead of the pallets of meats and cheeses being pushed and pulled to and from the stationary scale, now the Newcastle Systems scales and printers are effortlessly wheeled over to the fresh products.

Fabulous Fact: The PP12 Portable Power Package can operate for 6 to 8 hours at a time, get recharged overnight and be up and ready to use the next morning!

Scenario #3:

Nine operators working in the 1.3 million sq. ft. warehouse, yard, and office space of a leading international manufacturer of agricultural and construction equipment that stocks 240,000 SKUs had to hike to one PC/ printer station. Once they finally got to the printer station, the operators could print their multiple product labels, depot tickets, routing tickets and other necessary documentation. Then, they had to hike back to the parts staging area with their arms cradling all sorts of labels and paperwork. It wasn’t uncommon for the wrong paperwork to get attached to the wrong job and get shipped to the wrong destination, creating a whole new scenario of delays and customer service challenges that had to be resolved.

Solution #3:

The international manufacturer invested in 50 mobile on-demand printing stations consisting of a laptop, two high-volume thermal printers, and the NB440 Mobile Powered Workstation. Used throughout the warehouse, these mobile on-demand printing stations can be effortlessly moved down the aisles by the operators, enabling ease and accuracy when printing labels, tickets, and documentation as orders are processed.

Fabulous fact: the NB440 Mobile Powered Workstation has two (2) 100 AH batteries and a standard power package that can power the laptop and the printers for up to 10+ hours.

2. Give Your Customers What They Want

Whether your customers are distributors or end-users, ultimately they all want, expect and hope for the same thing from doing business with your company: world-class customer service and on time, accurate delivery of their products. They want to completely avoid the stress and frustration of waiting for their order only to discover it’s been mislabeled and shipped to the wrong location. They want their products on time, every time.

Your customers don’t need to know that your warehouse, yard or office space is over a million square feet and stocks hundreds of thousands of SKUs. They don’t need to know that their order is lost, late or misplaced because you only have one stationary PC/printer workstation for all your warehouse employees to use to print multiple product work labels, depot tickets, routing tickets and any other necessary documentation. What they need is to feel that they are your only customer and that their particular order is accurate, and is given top priority and care in handling. It’s impossible to achieve that when you have multiple workers vying (and waiting) to use the same static equipment all day long.

3. Reduce Unnecessary Downtime

Often, hidden downtime and delays in productivity at a huge warehouse or distribution center can easily go unnoticed for a long time, resulting in undue expenses and financial losses from sources you can’t readily pinpoint. What’s worse, it’s difficult to eliminate that lost time and money if you’re not immediately aware of it. If your facility has designated workstations ~ whether they’re built into walls or assigned to specific corner spaces, your employees are only able to weigh, label, or process the inventory at hand when they are physically at that stationary workstation. Add to that hidden downtime scenario a small and steady line of warehouse workers gathering around the static workstation waiting to use the equipment themselves, and your increase in downtime has just more than doubled.

Time is everyone’s most important and irreplaceable commodity. When your employees have to leave their assigned areas in order to effectively complete necessary tasks located in other areas of their work environment, time is lost. Whether they’re leaving their station to walk across the million-square-foot facility to print something, make a copy, deliver a report, obtain approval or get supplies, they are unintentionally being unproductive ~ wasting precious expensive time that can never be regained.

Hidden downtime causes:

- A less productive employee

- Slow delivery rate to customers

- Decrease in satisfied customers

- A halt in production lines

- A loss of profit for the company in millions of dollars

Enabling your employees to take their work with them as they move throughout your facility cuts down on the time they previously had to spend physically going from point A to point B throughout any given shift. Mobile workstations with portable power instantly reduce downtime for employees.

4. Provide Your Workers with the Proper Equipment to Perform Their Jobs Well

Since the processes and procedures as well as the number of personnel and size of your facility are unique to your particular company, the equipment you choose to create a highly-efficient and solution-centered operation should be just as distinct. In your industry, a one-size workstation does not fit all.

If you are performing any combination of the following tasks, a mobile workstation can be configured to optimize your productivity.

- Inventory management

- Process control

- On-demand label printing

- Product testing

- Order picking

- Cross-docking

- Bar coding

- Weighing

- Scanning

- Inbound-product receiving

- Inspecting

- Rerouting

Here’s a look at just four of the many diverse choices you can consider:

Compact RC Series

The most streamlined, user-friendly, and economical compact cart systems for laptops. The 4 different models of the RC Series are designed with 11 gauge steel and full-reinforced surface. You can opt for a powered or non-powered mobile cart. Whichever you decide, they are all rugged, built to withstand the demands of warehouse operations. They come with 5†swivel casters that lock, an integrated push handle and a convenient 18†storage compartment. Only 18.5†wide, the RC Series has a purposefullysmall footprint to maneuver easily throughout the tight and narrow spaces in your facility.

Mid-Range NB Series

The patented NB Series Mobile Powered Workstation was designed to provide true mobility anywhere throughout your facility. It can run up to 4 devices at one time during a typical shift between 8 to 12 hours. Its 3 shelves and accessories can be adjusted in seconds to suit your operators’ needs. Your operators can get realtime access to WMS, ERP, and automated data collection in moments.

Heavy-Duty PC Series

Developed to hold and power a variety of equipment, this option provides generous space to hold inventory. It has seamless rechargeable power and the ability to run several devices at once, including a laser printer for 8-12 hours of normal use. It’s easily adjustable, can be configured for any application, and can be moved and positioned with minimal effort throughout your facility.

Power Swap System

If you run a multiple-shift, 24 hour operation, your printers, computers, scales, and other hardware need to be able to run 24 hours a day, too. The Power Swap System does that. When the battery power runs low, your operator can simply swap it out for a fully-charged one in about 30 seconds.

5. An Increase in Productivity

In order for your company’s employees to perform their jobs well and to be as productive as possible, they have to be equipped with the best tools. While you may have employed a team of exceptional workers with a great work ethic and a commitment to excellence, if they don’t have the proper equipment to do their jobs as efficiently, correctly, and easily as possible, they’ll never be able to achieve the same level of productivity as they would if they were armed with the right gear.

Creating wireless mobile workstations that can be both effortlessly wheeled across warehouse floors and easily maneuvered through snug aisles instantly increases the amount of work your warehouse team can get done during any given shift. Instead of continuing to have your distribution personnel unintentionally waste minutes (that quickly add up to hours) by frequently walking back and forth to a stationary scale, printer and computer in some corner of the space, they can instead have fully equipped, mobile powered workstations conveniently within arm’s reach.

With a mobile central command center, your employees have everything they need to get their jobs done – right at their fingertips. As your employees move to different areas of the warehouse, building, or office, they can bring their own assigned stand-up workstations with them. In addition, they have instant access to real-time data and sensitive information. This eliminates all the additional time previously spent asking someone else to look something up on a computer or having to wait until a colleague is done using the one stationary computer before they can complete their project.

As a result, productivity is instantly increased. More gets accomplished and all that downtime previously spent traveling by foot and waiting to use an available piece of equipment gets completely eliminated. Productivity doesn’t just suddenly happen in the workplace. While a commitment to excellence and a focused work effort contribute to it, productivity also requires intelligent planning to create the best work environment, equipped with the best tools.

By increasing productivity and eliminating the time and labor spent walking from one location in a warehouse to a static scale, printer or computer, you can save thousands of dollars, thousands of labor hours and thousands of moments of frustration per year. You can experience:

- An increase in receiving volume up to 65%

- A reduction in labor costs by $5,000 per operator

- An elimination of overtime by up to 75%

6. A Return on Investment

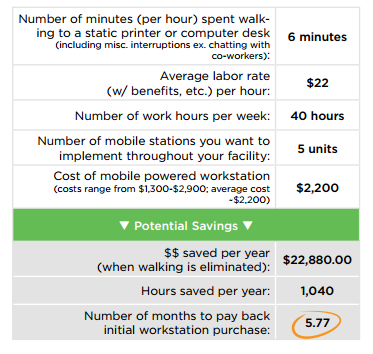

Here’s a sample return on investment calculation to demonstrate the increase in productivity, the savings in labor hours, and the money saved by implementing mobile workstations at your company:

7. Where Customized Solutions are Necessary

Your facility is unique. The capital equipment you invest in should be just as customized, authentic and distinctive as your operations. Although the printers, scales and computers you may be having your staff use currently are getting the job done eventually, the time, effort and expense it is ultimately costing your company is enabling your competitors with high-tech, state-of-the art tools to get their products to their consumers at lightning speed.

State-of-the-art industrial carts are outfitted with what your distribution center’s particular needs are. Also referred to as “stand-up workstationsâ€, mobile powered workstations are essentially industrial carts with all the tools and power your employees need to do their job on the go. The industrial carts you choose can be outfitted and customized with any number of tools and utilities, based upon your company’s particular needs. Small in size and easy to maneuver, they can literally go anywhere, allowing your employees the freedom of movement to take their work with them.

8. Improve Your Workflow

Continuing to move forward, to advance operations and to implement better processes leads to improved workflow. Implementing the right mobile workstation at your facility can help you create and maintain a gap-free and highly-efficient warehouse environment. This is important not only for your customers expecting (and deserving) the correct and timely delivery of their products, but also for your team receiving, labeling, shelving, organizing, locating, pulling and shipping those products. A mobile powered workstation can increase workflow efficiency by:

- Minimizing the amount of time spent accessing antiquated systems for the weighing and labeling products

- Increasing the expediency and accuracy of organizing and locating inventory

- Enhancing your distribution center’s communications capabilities both internally and via their ability to access critical data and information needed at a moment’s notice

With the various applications, tools and devices you choose for your workstation, your system will inherently streamline and expedite your team’s ability to handle and process inventory accurately and quickly.

Being able to access all of a product’s data – including both recent and past information, and then immediately share that information with other professionals on the team has never been easier than with the implementation of a complete mobile workstation that optimizes workflow.

9. Tax Break Opportunities

With the fairly recent changes that were made to Section 179 of the IRS Tax Code, you are now able to deduct up to $25,000 of the cost of all the capital equipment and any other assets you purchased for your business in the same year that you purchased the equipment. These changes were made in the tax code as an effort to spark the American economy by inspiring businesses to purchase, finance or lease new or used capital equipment in 2014. Although you are allotted up to a $25,000 tax deduction, if you invest more than $200,000 in warehouse equipment during 2014, the amount of the deduction decreases on a dollar-to-dollar scale.

Instead of having your company go through the arduous and drawn-out process of depreciating the cost of your powered workstations over several years, you are now able to write off the entire purchase price (up to $25,000) in the year 8. Improve Your Workflow You Can’t Afford Not to… 9. Tax Break Opportunities You Can’t Afford to Miss out on… 11 11 you purchase and roll out your new powered workstations!

Whether you spend $4,000 on a portable, powered industrial warehouse cart or over $100,000 on multiple workstations for multiple locations, you can deduct the full $4,000 or up to $25,000 on the $100,000 straight away. Should you purchase $25,000 in equipment, you’ll receive a $25,000 tax reduction under Section 179 and experience a total cash savings (35% tax rate) of $8,750. Your total investment in your new equipment, after deductions, would be just $16,250.

If you appreciate and embrace money-saving incentives for your business and simultaneously want to provide solutions that improve your warehouse operations, you can’t afford to miss out on this tax break opportunity – especially since business tax codes often change each tax season.