Bar Coding and RFID Enable Food Supply Chain Traceability and Safety

In the early days of bar coding, an Efficient Foodservice Response (EFR) study identified $847 million in savings potentially available by expanding bar coding within the food supply chain. Since then, the U.S. Bioterrorism Act, European Union Food Law, and Hazard Analysis and Critical Control Points (HACCP) requirements mandate improved product identification and traceability. Today, technologies, techniques, and standards exist to help organizations throughout the food supply chain gain complete traceability for safety, compliance, and business process improvement.

Momentum is growing to implement whole-chain traceability, which includes internal and external visibility, from the grower, through the distributor, to the retailer. A key industry effort is the Produce Traceability Initiative (PTI), which strives to achieve supply chain-wide adoption of electronic traceability of every case of produce by 2012. Once fully adopted, PTI will improve the effectiveness of current trace-back procedures while enabling common standards for future traceability systems.

This white paper examines how the food industry can take advantage of bar code and radio frequency identification (RFID) technologies to improve safety, reduce operating expenses, meet compliance requirements, and improve efficiency. It covers:

-

- How bar code and RFID support compliance with regulations such as the Bioterrorism Act , EU Food Law, and The Food Safety Enhancement Act (H.R. 2749)

-

- Traditional uses and advantages of bar code data collection

-

- Emerging technologies and standards, including Reduced Space Symbology (RSS) bar codes, Electronic Product Code (EPC) RFID technology, and the GS1 Global Traceability Standard (GS1 DataBar).

The Need for Food Traceability is Real

Food manufacturers and distributors are looking at supply chain visibility technologies to improve food safety and consumer confidence. The April 2010 salmonella outbreak resulted in over 1,000 people becoming sick, the recall of over 550 million eggs, and a tarnished image of the poultry industry. This scenario is a prime example of where RFID and bar codes coupled with supply chain collaboration can provide timely, actionable data related to the movement of goods throughout the supply chain and traceability for regulatory compliance.

In fact, the burden of compliance and food safety prevention often depends on active efforts within the food industry. According to the Food Manufacturing Update:

“The FDA’s Food Protection Plan (November 2007) focuses on a three-pronged initiative for increased food safety: prevention (promoting increased corporate responsibility so that food problems do not occur in the first place), intervention (risk-based inspections, sampling and surveillance at high risk points) and response (communicate clearly with consumers and other stakeholders during and after emergencies). According to survey results, 60 percent of respondents felt that the FDA’s biggest weakness lies in its prevention efforts.”

Unfortunately, traceability in the U.S. food supply chain is moving at a slow pace. Health and Human Services reports that 59 percent of the North American food facilities surveyed did not meet the FDA’s requirements to maintain records about their sources, recipients, and transporters.2 This lack of compliance places more burden on an already stretched FDA to track down the origins of food borne illnesses. Moving RFID and bar code labeling and scanning deeper in food grower, shipping and packaging chains enables easier tracing throughout the product life cycle.

Full food supply chain visibility provides an extra layer of protection when a food borne illness occurs, such as the salmonella outbreak mentioned earlier. Visibility allows growers and distributors to determine if the contamination occurred at the grower, or was introduced within the distribution process, and who might else be affected. Adding this level of visibility can:

“Save lives in the case of a severe food-borne illness outbreak as well as save a business time, money, and reputation.”

Consider the following case example. A Zebra Technologies customer in the baking industry reduced its inventory and distribution costs by $3 million in the first year after installing an automated pallet labeling and identification system. The company, which operates six warehouses throughout the U.S. and previously was not able to measure and balance inventory throughout its operations, began printing and applying bar code labels to all its cases and pallets and then scanning the bar codes to capture quantity, location and product identification numbers, including lot codes.

The system enabled the company to gain an accurate, timely view of inventory and to increase the average number of pallets per shipment from 47 to 61, a 30 percent improvement. By increasing load yields, the company significantly reduced the need for expensive less-than-truckload (LTL) shipments to customers to fulfill orders, which contributed greatly to cost savings.

Shortly after implementing the system, the company recalled some products because it received a bad batch of ingredients from a supplier. Using the lot number information captured from bar code scanning, the company traced its shipments and conducted a highly targeted recall by contacting only those customers who had received the affected products. The recall completed quickly, with minimized cost, and without having to pull unaffected products from store shelves.

The bar code traceability system described above is typical, and relies on standard, commonly used linear bar code formats for cases and pallets. Increased traceability and other applications are possible using more advanced, standardized identification technologies such as GS1 DataBar (RSS) bar codes and RFID. RSS targets produce, loose items, and other difficult to identify products. There are high data capacity versions of RSS that enable encoding of lot codes or other traceability information.

The EPC RFID system creates a unique serial number for each item (in contrast to a U.P.C./EAN number that identifies the product type and manufacturer), which is very helpful for traceability applications. Rewritable RFID tags that have extra memory sufficient for lot codes and other information support EPC. Encoders can update RFID tags with time stamps and transaction records to create electronic pedigrees. Smart tags (battery-powered RFID) can record temperatures and other environmental data critical for the fresh produce industry.

Improving Identification Helps Business

Traceability technologies provide efficient, accurate ways to comply with regulations such as the Bioterrorism Act and the EU Food Law, which require businesses to collect, process, and store vast amounts of information. Recent legislation in the U.S. includes the Food Safety Enhancement Act of 2009 (H.R. 2749), which seeks to improve the safety of food from both domestic and international sources. PTI uses a Global Trade Item Number (GTIN) to achieve traceability4. The GTIN includes a GS1 company prefix and a unique item reference number compatible with UPC bar codes, and RFID or human readable codes.

Automated data collection removes much of the time and expenses required for data processing, while building a foundation for other efficient business processes. Data collection by bar code and RFID is exceptionally accurate (accuracy often tops 99 percent), which can help prevent errors in order picking and shipping that plague the food industry.

Bar code scanning records product codes, lot numbers, invoice data, order numbers, and other information in less than a second. Gathering this information manually is time consuming, because workers must first record the information at the point of activity, then transcribe and enter the data into the computer system. The redundant manual data recording procedures provide two opportunities to record the information incorrectly. Errors occur in 36 percent of consumer-packaged goods orders according to a study by the Grocery Manufacturers Association (GMA). Such errors lead to inventory inaccuracy and eventually to out-of-stocks—acknowledged as a multi-billion dollar problem.

Consider the effect of a common shipping error in which an employee picks the wrong SKU to fulfill a customer order. The customer might discover the error while validating the shipment at receiving, and would engage the delivery driver to help resolve it. If someone discovered the error later, it would result in a call to the supplier’s sales or customer service department. In either case, the distributor incurs labor charges to research and correct the mistake.

Involving the driver at the time of delivery creates delays that would cause the driver to miss delivery windows with other customers, causing additional problems and possibly creating the need for an additional, rush shipment from the distribution center. The customer will hold up payment of the invoice until the error is resolved, slowing the cash cycle. These actions, which all trace back to a preventable warehouse picking error, can have a significant impact on productivity and profitability if they become an accepted part of doing business.

For example, a hypothetical company earning a 3 percent profit margin makes an average of only one shipping error per day (which is a very conservative estimate considering the GMA study found 36 percent of orders contain at least one error). If each error takes 20 minutes to resolve, the company spends 10 hours a month on error resolution. If the average labor cost for pre-sales and delivery personnel, customer service representatives and warehouse workers is $25 an hour (which does not include shipping expenses), the monthly labor cost for error resolution is $250. The per-error resolution cost is $8.33 (1/3 of an hour of labor worth $25/hour). At a 3 percent profit margin, the company must make $8,333 in new sales to offset the monthly error costs.

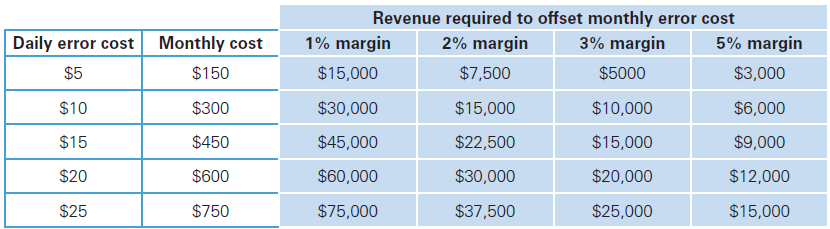

The following table shows a sampling of the revenue required to offset the errors based on different costs per error and different profit margins. Calculations assume one error per day and 30 days per month.

The table illustrates how common picking and shipping errors can have significant impact on profitability. It also underscores the value of using bar code and RFID technologies to identify goods accurately throughout the supply chain. High-profile business improvement initiatives like Global Data Synchronization (GDS), total supply chain visibility, and electronic pedigrees all rely on accurate identification on the case and pallet level that RFID and bar code systems provide.

Standards and Tools for Traceability

By using automated data collection, systems and processes created to meet traceability requirements can also improve business efficiency and reduce costs. The Bioterrorism Act and EU Food Law require traceability one step forward and one step back through the supply chain, which requires timely, accurate information exchange between trading partners. The Global Data Synchronization (GDS) system provides a standardized framework for all supply chain parties to consistently identify products and communicate data.

GDS makes use of the GTIN identification standard from GS1 (formerly UCC/EAN), which is widely used throughout the world. GTIN numbers usually encode in U.P.C./EAN bar codes at the item level, or other GS1-standard bar code formats (e.g., SSCC-18, UCC-128, and SGTIN) at the case and pallet levels. Other encoding options are gaining adoption to support the food industry’s needs for increased traceability. GTIN is the basis for EPC numbers (the EPC standard system also administers under the GS1 umbrella) for unique item identification by RFID tags.

Users can also encode GTINs in RSS bar codes, with additional capacity to encode lot codes and data useful for more precise identification and traceability. GS1 established January 1, 2010, as the starting date for bar code scanning systems to be capable of processing GS1 DataBar (RSS) symbols. The date is a foundation step to prepare for RSS to replace U.P.C./EAN as the primary bar code format used to identify consumer goods.5

GS1 has also created the Global Traceability Standard, which establishes processes for identifying any type of item globally, in any or multiple supply chains. The GMA, the Canadian Produce Marketing Association, and PTI sponsors are among the organizations that have expressed support for the standard. More information about the standard is available at www.gs1.org.

The following sections explain how to use bar code and RFID to gain visibility and accuracy within internal operations, and to gain data to support external supply chain visibility initiatives such as PTI and H.R. 2749.

Improve Receiving Dock Productivity

For traditional receiving applications, workers can scan a bar code label on incoming shipments to record the item’s arrival. If shipments are labeled with RFID smart labels, an RFID encoder at the receiving dock can be used to automatically apply a time and date stamp and the Global Location Number (part of the GS1 standard system) to document the receiving point. For traditional bar code systems, the scanning receipt can trigger a software application to update records automatically with the same data. Putaway locations and other data can also be included with the record for even more traceability.

The absence of bar codes or other identification on cases, and poor quality symbols on cases with labels, presents a major obstacle to efficient warehouse operations in the food industry. Only about 64 percent to 83 percent of cases delivered to food distribution centers use bar code, according to EFR. Many of the cases are marked with low-quality bar code symbols printed directly on the corrugated packaging material, which are often unreadable. Printing bar codes on separate labels applied to the packaging dramatically increases read rates and improves overall system performance.

Given the tremendous value of bar code-based warehouse management operations, and the relative ineffectiveness of supplier bar coding efforts, food distributors should install bar code labeling equipment to mark incoming materials at the receiving area. Bar code label printers are rugged enough for use anywhere within the warehouse, and can connect to host systems through a variety of interfaces, including wireless communication. Bar code label printing systems are inexpensive to operate, and have the flexibility to connect to any legacy computer, network, and software system. They can significantly improve the performance and return on investment of warehouse management, inventory control, and shipping systems. If distributors are required to provide RFID-tagged shipments to customers, then workers should encode and apply RFID smart labels at receiving rather than when the business ships cartons. Doing so enables internal tracing benefits.

Traditionally, workers scan bar code labels at receiving to record receipt and update inventory records. Manual bar code scanning can be replaced with automatic RFID read portals to reduce the time and labor required. EPCglobal calculated savings of between $0.01 and $0.03 per case when receiving occurs with RFID instead of bar coding.6 Primary benefits are labor savings and improved accuracy resulting from fewer miscounted or unidentified products. The data came from a seven-month study of EPC-enabled receiving operations at an actual distribution center. The study also found that receiving errors were the root cause of 58 percent of all shipment shortages and overages. These errors contributed to out-of-stocks, a data point also factored into the benefit calculation. Out-of-stocks result in $6 billion in lost sales annually, and the average supermarket can reduce direct store delivery out-of-stocks by 2.9 percent and increase annual revenue by $75,000.

Enable Cross-Docking

Cross-docking tasks fail if workers cannot identify materials quickly and accurately, making bar code or RFID identification essential. Mobile bar code label printers are especially valuable for cross docking. Shipping and receiving workers equipped with mobile computers, bar code scanners and label printers can receive inbound shipments, and log them into the host warehouse or inventory control system with the mobile computer. Then workers can immediately generate a bar code shipping label with the required cross-dock information using the mobile printer, often mounted to a forklift or worn on a belt or shoulder strap. Wireless mobile printers connect directly to wireless LANs to manage communication between the host system and the warehouse worker.

RFID can also facilitate efficient cross docking. Incoming pallets or cartons with smart labels automatically route through conveyor systems to other dock doors because the fast-reading capabilities enable instant identification of the shipping container plus all of the individual items inside. For shipping, RFID readers can help packers quickly locate and aggregate all the items needed to complete the load.

Accurate Lot Control

Putting lot numbers and expiration dates on a bar code makes it easy to record the information accurately and automatically at any point in the supply chain. This capability improves data accuracy, while reducing the effort needed to record and transcribe the information. Production management, enterprise resource planning (ERP), environmental health and safety monitoring, and other systems frequently provide or require lot-level traceability, which means the supply chain may be the only area where the information is not readily available. Lot-level supply chain traceability is extremely valuable for batch-oriented food recalls; for an example, see the “Recall Management” section later in this white paper.

Lot numbers may be encoded into bar codes or RFID tags and applied to pallet-, case-, inner pack- or item-level packaging. Expressing lot codes in a bar code or RFID tag in addition to human-readable text enables scanning and processing by automated systems. Inventory management systems, for example, can use variable lot code or best-by information to reduce waste by ensuring that processes follow first-in, first-out (FIFO) requirements.

Encoding a lot number provides another level of identity that will help the industry meet traceability requirements. The globally standardized U.P.C./EAN bar codes used on products, and their associated case codes, are limited in their ability to provide traceability information because they only identify the manufacturer, product type and packaging level, but do not uniquely identify each item. Improved traceability requires an additional identifier, such as additional information encoded on the pallet label, which RSS and the EPC RFID system addresses. RSS originally was developed to allow variable data, such as lot codes or best-by dates, to be encoded on grocery items, as well as to provide the information necessary for checkout operations, all within a compact bar code label. The EPC system creates a unique serial number for each item, making it possible to conveniently associate specific products with lot and other production information held in central databases. There are also database and information sharing components of the EPC system to support rapid data exchange among supply chain partners.

Streamline Warehouse Management

Improved warehouse management rates as the top advantage of using bar codes, according to a 2005 EFR survey of food distributors. Implementing bar code systems throughout warehouse operations could save the food distribution industry more than $1 billion annually. Since the study, distribution centers are beginning to deploy RFID in distribution centers to assist shipping and receiving operations, and to help further reduce labor requirements.

Businesses typically use bar coding and RFID with warehouse management system (WMS) software packages, which perform a variety of functions to improve labor productivity, documentation, and efficiency. For example, a basic function of a WMS is to calculate the most efficient picking and putaway sequences, which will reduce required labor and handling. When supported with timely, accurate information, a WMS can manage inventory by expiration dates to reduce spoilage. Many WMS packages can also help generate required shipping labels, Electronic Data Interchange (EDI) transactions, and other required documentation.

Fulfill and Track Shipping Orders

A common bar code shipping application is for workers to scan each case and pallet loaded for transport to verify that all required items are included and to prevent items from being loaded onto the wrong truck. A wireless LAN connection communicates the bar code scans to the host computer, which compares the items loaded to the actual customer order. The system immediately detects incorrect or missing items and notifies shipping personnel. Shipment accuracy often exceeds 99 percent when using bar code data capture and real-time verification. Capturing outgoing shipment information automatically is an efficient way to build traceability records without requiring time-consuming manual data entry.

The food industry could expand this application to enhance safety and traceability by automatically capturing lot codes and expiration dates from outgoing items. The lot and expiration information can append to the record of the customer order. In the event of a shipment discrepancy or recall, the distributor would have the documentation needed to trace specific lots to specific customers. The lot codes or other variable information about the cases in a shipment can encode on a two-dimensional bar code applied to the pallet, which the logistics provider and receiving organization could read with a single scan to gather information about the entire contents of the pallet.

RFID provides similar functionality because every tagged case or package can be scanned simultaneously without requiring the pallet to be opened, a feature that is central to many of the cross-docking and other logistics advantages RFID can provide. At the point of shipping, as for receiving aggregated loads, RFID provides the highly desirable function of automatically recording what’s on a pallet (regardless of whether the goods are all of the same type or mixed), creating an electronic manifest of goods shipped or received. This is a unique and powerful core feature of modern RFID systems now deploying within retail supply chain operations

Accelerate Recall Management

Food recalls are a near daily occurrence and distributors need to have plans and processes in place to execute them quickly and efficiently. The degree of traceability suppliers and distributors have over their products is what determines the size, scope and expense of a recall.

The amount of information included on unit-of-use packaging can make the difference between a general, mass recall with notices going out in newspapers and TV news, and a highly targeted, limited recall where customers may receive notification by a phone call from their supplier. By including lot codes with shipping labels and other product identification, and marrying them with customer order and shipping records, businesses could communicate a recall using a format like:

“We are recalling 8-ounce packages of Ourbrandpasta, lot number 0123456789, made on March 19, 2003, between 8 a.m. and 1 p.m. on production line 2 at our Anytown, N.J., facility. These products shipped to Fictional Foodservice Distributor warehouses in Memphis, Tenn., and Columbus, Ohio. No other products are affected.”

The distributor could then execute its part of the rollout in a similar fashion by tracing the affected products to specific customer locations. Using RFID and EPC item-level traceability provides a similar level of control.

Production control systems and auditing procedures enable manufacturers to isolate quality or compliance problems at the lot level. By making lot-level traceability available throughout the supply chain with a bar code scan, businesses can recall specific quantities and shipments. This degree of traceability limits the logistics handling costs and administrative burden, so recalls can be resolved more quickly. The audit trail also limits liability exposure and prevents lawsuits from unaffected individuals. When businesses receive returned products, workers can check lot codes efficiently with a bar code scan, so the business can redistribute unaffected products quickly.

Simplify Returns Management

Variable information unit-of-use printing could have similar effects on returns management, although the benefits should be greater and immediate because returns are part of everyday business for producers and distributors. Returns may be subject to numerous local and national regulations regarding safe handling and transport, documentation and traceability. One of the best ways to collect the information and create the audit trail for regulatory compliance is to scan items with bar code readers, which offers easy programmability to attach a date-and-time record to every transaction. Scanning all movements and transfers and applying an automatic time-and-date stamp creates traceability and produces tremendous time and labor savings for data recording.

By setting shipping or database systems to record shipments to customers by specific lot number, manufacturers and distributors can verify that they receive authorized returns by quickly scanning an item label. This practice could also help detect unauthorized or counterfeit products. Scanning expiration dates will enable companies to determine if products are eligible for return and if they can redistribute returned products, or require disposal or special handling.

Tighten Container Management

Using automatic identification systems to track pallets, milk cartons, trays and other returnable containers can provide a strong return on investment by lowering operating expenses. Many producers and distributors lack accurate information about the quantity and location of their shipping containers because the assets often dwell at customer facilities, and are not returned promptly. As a result, businesses purchase more returnable containers to ensure they have an adequate supply, creating excess capacity and locking capital into fixed assets.

Identifying returnable containers and tracking them to customers provides the information businesses can use to improve returns and recoveries. The first step is to permanently identify each asset with a bar code label or RFID tag. Label material is available for permanent identification even when exposed to industrial cleaning, sterilization and cold storage conditions. Workers can scan the assets when they are loaded onto trucks at the distribution center, or in the field upon delivery. Systems could record the information in the customer record or order management system, or in a separate database. Returned assets would undergo scanning to check them back into the distribution center, similar to a video rental return.

Managers could consult the system software to get a real-time view of container availability. The customer could track outstanding containers, with documentation provided to aid return and recovery. By actively monitoring and managing container usage, businesses can improve cycle times and inventory turns, while lowering their fixed asset base.

Printing and Labeling Considerations

The applications and benefits described above all rely on accurate product identification. Bar code and RFID provide accuracy, but only if the printers and label material provide the quality and durability needed for food storage and supply chain operations. The following sections present considerations for selecting bar code and RFID formats, printer types, and label materials.

Pallet Marking

The Serial Shipping Container Code (SSCC) is a GS1 standard for identifying pallets and cases. The SSCC is an 18-digit number expressed in an EAN.UCC-128 symbology bar code, or encoded in an RFID smart label, that uniquely identifies the contents of the pallet or case. The SSCC number may be included in an EDI advance ship notice (ASN) to help the receiving organization automatically recognize the material when it arrives.

SSCC describes the contents of a pallet or case for a specific shipment, but is not typically used for permanent identification of the physical pallet. Pallets and other returnable containers should be marked with a separate unique identifier for asset management applications. Companies are free to develop their own serial numbering system to identify each asset or may use the GS1 Global Returnable Asset Identifier (GRAI) standard. The standard provides a numbering system that identifies the asset and its owner, describes the asset type (keg, pallet, etc.) and allows users to add their own unique serial number. The information encodes in a bar code and/or RFID tag.

Case Marking

Cartons within a case or pallet should receive their own bar code labels to facilitate automated warehouse, shipping, and receiving applications. The SSCC data structure and EAN.UCC-128 bar code symbology are suitable for case marking. Regardless of the numbering system or bar code symbology selected, cases should always be marked with a label to ensure readability.

Workers create case codes by inkjet printing directly onto the packaging material, which often fails to produce the quality needed for scanning the bar code. An EFR study of 1,896 different suppliers found that 18 percent of all case codes were unreadable. Inkjet printing does not provide enough control over how the packaging material absorbs the ink. The printed image spreads as the ink soaks in to the cardboard, which often produces bars and spaces that are out of tolerance for successful bar code reading.

Thermal label printers meet the precise print tolerances that bar codes require. As with pallet marking, automated print-and-apply systems have the speed, bar code support, print quality and variable data processing capabilities required for successful case coding. Advanced thermal printers also have connectivity and other features that improve productivity and labeling accuracy.

A yogurt producer implemented an automated print-and-apply system to maintain high throughput and reduce packaging changeover time on its five production lines. The company supplies thousands of retail outlets and does private labeling for multiple customers, which requires frequent changes to the label format applied to finished products. When customers began requesting GS1-standard case codes on packaging, the manufacturer installed Zebra print engines with a wireless interface and automated applicators to satisfy its marking requirements.

When the line needs to change to begin labeling for a different customer, an operator finds the customer name on a menu sheet and scans the corresponding bar code. The scan triggers a database lookup on the host computer, which retrieves the appropriate label format. The host computer communicates the new label format to the Zebra print engine over a wireless LAN connection. The print engine receives the wireless transmission and automatically begins producing the new labels. The first label prints within 1.5 seconds of the operator scanning the customer code, resulting in extremely fast changeovers and high productivity.

Environmental Considerations

The physical label remains vital when planning applications, data content, and bar code formats. The temperature extremes and temperature changes that are common in food operations pose several challenges to label performance. Ensuring that labels will remain affixed and the bar codes will remain readable requires planning for all the conditions the labels experience throughout the supply chain, including the environments they will face after they leave the facility.

Moisture and temperature extremes can cause adhesive to fail, and moisture can also damage the surface of an unprotected label and make the bar code unreadable. Because cold and moisture are commonplace in refrigerated and frozen food warehouses, specialty label material is often required. The Zebra Z-Select 4000T All Temp is freezer-grade label material that withstands exposure to temperatures as low as -65º F and has a coated face stock to protect the bar code image permanently. Other synthetic and paper materials are available that withstand heat, moisture, blood, cleaning materials and other potential hazards.

Enhance Food Traceability and Visibility

Tighter traceability does not have to burden business. Companies in the food industry can take advantage of proven traceability tools and techniques to improve food safety and tighten their own operations by driving out excess inventory, storage, and handling costs. All of the benefits described in this paper result from improved identification, which is accomplished most efficiently through the use of bar code, RFID and related systems. Many companies in the food industry rely on printers, label materials, and wireless connectivity solutions from Zebra to help meet their identification and labeling needs.