Datamax-O’Neil’s I-Class printer helps manufacturer respond to government requirements and gain higher productivity and profitability

In 2008, the Food and Drug Administration in China passed legislation that required pharmaceutical enterprises involved in the manufacture and distribution of pharmaceutical products to apply barcode identification on all unit-dose medical product packaging. As a pharmaceutical manufacturer specializing in vaccine production, Wuhan Institute of Biological Products had to find a barcode solution to meet the requirements set by the legislation. They sought the help of Datamax-O’Neil to implement a track-and-trace solution, using Datamax-O’Neil’s I-Class series industrial printers.

In 2008, the Food and Drug Administration in China passed legislation that required pharmaceutical enterprises involved in the manufacture and distribution of pharmaceutical products to apply barcode identification on all unit-dose medical product packaging. As a pharmaceutical manufacturer specializing in vaccine production, Wuhan Institute of Biological Products had to find a barcode solution to meet the requirements set by the legislation. They sought the help of Datamax-O’Neil to implement a track-and-trace solution, using Datamax-O’Neil’s I-Class series industrial printers.

Wuhan Institute of Biological Products produces an average of more than 100,000 vials of various vaccines daily. These vaccines have to be delivered to health and epidemic prevention stations as well as disease control centers throughout China on time and uninterrupted to meet the daily needs of disease control and prevention. While complying with the new legislation, they also had to ensure that product identification in the manufacturing process would not impact the existing production flow or slow down productivity. To support this, the Institute required an industrial strength printer that it could rely on for mission critical and accurate barcode label printing.

Enter the I-Class series printers. The I-4208 and I-4308 barcode printers feature a tough, modular design that includes a die-cast aluminum frame that assures durability and rugged reliability. The printers come with a standard 32Bit processor and 8MB (16MB) of standard memory for fast first-label output and print speed of 8 inches per second, with a printing resolution of 203dpi (I4208) and 300dpi (I4308) respectively, perfect for printing clear and accurate barcode labels for medical packages that come in varying sizes.

H&M Bay leverages RFID solutions from Motorola to accelerate cold storage freight transfer

The company: H&M Bay, Inc.

In business for more than 25 years, H&M Bay provides efficient, reliable transport of temperature-controlled less-than-truckload (LTL) freight. H&M Bay has distribution centers in California, Florida, Maryland, Massachusetts, North Carolina, and Washington. With its strategically located distribution centers and an owner/operator network of over 10,000, H&M Bay provides industryleading delivery to companies throughout the continental U.S.

The challenge: Fast, efficient product handling and inventory tracking

In the LTL freight industry, time is always a major factor in successfully meeting customers’ needs. When temperature control is required, a focus on operational efficiency is critical, and efficiency is a guiding principle at H&M Bay.

Being the premier freight mover in the LTL frozen and refrigerated commodities market, H&M Bay is always looking at ways to increase service excellence. One example is the company’s custom Web-based dispatch system designed and implemented by John Walker, H&M Bay’s software development manager. The web based system was designed to allow customers and remote workers access to critical operations data 24×7. The customer Extranet opens up the dispatch operations of H&M via online order entry and real time push or pull shipment tracking. Tight integration with the Microsoft Navision Accounting application provides customer and vendor account insight tightly integrated with shipment information.

American Apparel Finds the Right Fit with Motorola RFID

Company overview

American Apparel is a manufacturer, distributor, and retailer of branded fashion apparel based in Los Angeles. The company started in 1989 as a wholesaler of t-shirts and opened its first retail outlets in 2003. As of mid 2008, American Apparel operates over 200 retail stores in 18 countries and the chain is still growing rapidly.

All of American Apparel’s products are manufactured in the United States; its wholesale business supplies its cotton-based casual wear to distributors and screen printers. The company is a vertically integrated operation and conducts its own knitting, dying, cutting and sewing, and design out of its headquarters in downtown Los Angeles. American Apparel’s young, metropolitan customers are very loyal to the brand.

The challenge: improve business processes and reduce lost sales attributable to out-of-stocks

American Apparel retail stores operate boutique-style, stocking only one item of each style, color and size on the floor at any time. Inventory turnover is quick and traffic between the stock room and the sales floor is high, particularly during busy hours. With more than 26,000 SKU items to manage, maintaining accurate inventory counts and a 100% stock mix on the floor consumed significant time and labor. However, both were considered critical to the chain’s success, since inventory errors and stocking delays translated directly into lost sales.

The potential benefits of reducing labor and increasing sales from deploying an item-level RFID operation at American Apparel were clear. And given the control it has over its manufacturing, distribution and retail operations, American Apparel’s plan was not only to reap the benefits of RFID on the retail floor, but throughout its closed loop supply chain. The company was eager to test the current capabilities of RFID for accuracy, performance and adaptability to American Apparel’s business processes, with four clear goals for process improvements:

- Increased stock visibility

- Improved accuracy/reliability of inventory counts

- Decreased labor costs and human errors associated with inventory

- Sales floor stock levels maintained at virtually 100%

Planning the pilot: the right location and the right partners to test the potential of item-level RFID

American Apparel gave careful consideration to its choice of store for the pilot. They were looking for a store that had average sales and a dedicated staff that would embrace the technology and a new process for inventory management. In addition, they wanted a location with good traffic flow that was centrally located to other area stores, to facilitate a regional roll-out if the single store pilot proved successful. Ultimately, the store chosen was the Columbia University area store in New York City, which also serves as the returns center for all the American Apparel New York City stores.

Equal consideration was given to the technology partners who would support the pilot. To give item level RFID a legitimate test in a real-world retail environment, American Apparel wanted to start with proven and universally-deployed hardware and software. Based on their market leadership and technology innovation, American Apparel chose Motorola MC9090-G RFID handheld readers for product commissioning and cycle counting. Motorola XR440 fixed readers with AN400 antennas were deployed to track stock moving from the backroom to the sales floor, and also at the point of sale to indicate a sale, decrement inventory, and trigger a product replenish. The retailer also used tags from Avery Dennison’s Retail Information Services combined with Vue Technologies’ TrueVUE Platform.

The TrueVUE platform offers retailers a streamlined, scalable platform that offers increased visibility into inventory levels, location and authenticity. The initial deployment of American Apparel’s pilot system placed RFID tags on each item of clothing and merchandise within American Apparel’s Columbia University area store in New York City.

Operation: Improve Asset Management

From weapons to desks and chairs, the U.S. Army relies on the Property Book Unit Supply Enhanced (PBUSE) system to track Army assets and automate property accountability processes across the supply chain while providing for greater visibility of these assets. PBUSE, the U.S. Army’s Web-based property accountability and tracking system, is part of the Global Combat Support System for both garrison and tactical units. Intermec solutions are at the core of helping PBUSE minimize their inventory tracking costs.

The Intermec solution consists of the CK61 rugged mobile computer and the PM4i Thermal Printer. This solution covers close to 13,000 military locations and manages tens of millions of inventory items for the Army at any given time. By minimizing the footprint cost on and off the battlefield, the Intermec solution has improved inventory asset management by 80 percent, saving the U.S. Army over half a million dollars in permanently lost or misplaced inventory and additional costs to individual soldiers.

At a critical time in the U.S. Army’s history with two major wars taking place, the Army has no room for error when it comes to keeping track of equipment on the battlefield, as well as, in the warehouse. However it has become increasingly difficult to track inventory, particularly as it relates to deployed units. Due to a paper-based, data entry, receipt system, PBUSE has been hampered by inefficient asset tracking processes used to confirm inventory.

Datamax-O’Neil’s Microflash 4t printer Makes NYPD Parking Citations More Accurate and Efficient

Cautionary words to those who park in New York City— obey the rules, or pay the price. A computerized parking citation system rolling out to the NYPD’s parking enforcement division will effectively eliminate hand-written traffic tickets. The result: a more accurate, efficient and cost effective solution. City officials say the new system will significantly reduce errors associated with hand-written tickets and, according to some estimates; realize millions in unpaid fines owed the city.

The solution consists of Symbol Technologies’ handheld computer, the PPT 2800, and Datamax-O’Neil’s portable Microflash 4t thermal printer. The terminal’s pocket PC platform and features, including bar code scanning and real-time wireless communications, allow officers to scan vehicle registration stickers, print tickets, and upload the information to a central database.

The solution works well in New York City, as New York State requires that all vehicles have their registration affixed to the inside of the windshield. The registration includes a 2-D barcode, which the parking officer scans using the handheld computer, and information about the vehicle is instantly and accurately captured. A traffic summons is printed on the spot by the wearable thermal printer, which is connected to the PC via a wireless LAN.

Invisible Barcodes for Security and Inventory Management Applications

Kodak is introducing a new virtually invisible clear ink. KODAK NEXPRESS Red Fluorescing Dry Ink is clear to the naked eye, but becomes red fluorescing when illuminated with an appropriate ultraviolet (UV) light source. The ink can be used to print unobtrusive images and non-reproducible bar codes on various printed materials, which then can be read with specialized bar code readers. The NEXPRESS Red Fluorescing Dry Ink enables a wide range of security and inventory management applications, including certified documents, such as medical prescription pads, drivers’ licenses and event tickets.

“This innovative expansion of the NEXPRESS Fifth Imaging Unit Solutions allows digital print service providers to enter the lucrative and growing secure documents and ‘track and trace’ markets,” said Steve Fletcher, General Manager, Electrophotographic Printing Solutions, Vice President, Kodak. “The amazing versatility of the family of KODAK NEXPRESS Digital Production Color Presses is designed to help print service providers stay on the forefront of a demanding, quickly changing marketplace.”

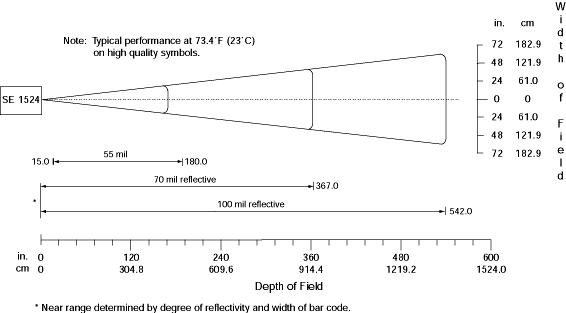

Decode Zone for the MC9000 Equipped with a Lorax 1D Long Range Barcode Scanner

The SE-1524ER “Lorax” is the barcode scanning engine that is used in some models of the Motorola MC9000 Series and other 1D long range barcode scanners. The SE-1524ER depth of field diagram shows the decode zone information.

With a large and reflective barcode, scans can be made successfully up to 45 feet away!

Great Styles, Great Service, and Great Gift Cards Printed on Site with Zebra Card Printers Print Gift Cards on Site for shopLAstyle.com

Cynthia Rojas’ original concept behind shopLAstyle.com was to create a site that features great Los Angeles based designers.

“Some great designers, such as Louis Verdad, Gorjana, and Vince, are based out of LA and we were very excited to be one of the first sites to ever carry these lines,” explains Rojas. “Later, we came across terrific lines such as Rebecca Taylor and Notify, who happen to be based out of New York and Italy respectively, and we just couldn’t pass them up. So, although we mainly carry Los Angeles designers, we won’t pass up lines that aren’t LA based.

“We provide our customers with great clothing from a variety of designers and an easy to use site that gets orders quickly to our customers, for which we get raves,” adds Rojas. “From simple C & C California tees designed by two California girls to the sexy, yet feminine, designs of Sass and Bide, designed by two Aussie girls, ShopLAstyle has evolved into a site that is dedicated to showing our customers exciting fashions that can’t necessarily be bought elsewhere.

“Because fashion is constantly changing, so does our site. We receive new merchandise on a weekly basis so customers check back often and sign up for our mailing list to receive emails about new items and special offers,” Rojas emphasizes. “That’s why we felt it was so important to create our own gift cards on site and on-demand. Buying a large quantity of pre-printed gift cards from an outside vendor didn’t make sense to us.”

The solution to the client’s ID verification issues was to create a custom application that would provide real-time verification of ID credentials and access authorization using wireless portable data terminals and Zebra P640i card printers. The enhanced features of the P640i enabled the issuance of highly secure ID badges that serve both as employee identification and access verification. While the current system utilizes bar code technology to verify each distinctive credential, it is designed to accommodate migration to new ID cards armed with UHF RFID technology. UHF RFID credentials enhance ID verification by leveraging time and distance as factors in data recognition and retrieval.

Zebra Mobile Printers and Motorola Mobile Computers Help Chicago Gasoline Hauling Company Improve Efficiency and Service to Customers

McMahon Cartage is a gasoline hauling and delivery company that services gas stations and trucking companies in the Chicago area. It employs 32 drivers to deliver approximately 5. 5 million gallons of gas a week to more than 300 gas stations.

Challenge

Three years ago, McMahon Cartage determined that its delivery system was inefficient and decided to streamline the process. “In the old system, a gas station owner called the distributor; then the distributor called us and we entered the load into the system; finally, we called the driver to give him the information,” John McMahon, vice president of McMahon Cartage, explains. “Each delivery had to go through four people before it made it to the driver. As a result, there was a lot of miscommunication and wasted time. ”

“Because we had so many steps in the process,”McMahon continues, “there were more chances of making mistakes. Plus, we had no way to track our orders. If something went wrong, everyone was pointing fingers at someone else. ”

In addition to the lack of accountability, drivers often got lost on their routes or wrote down the wrong name of the gas station on their order, resulting in the driver being held responsible for the billing inaccuracy, which could mean as much as $30,000 taken out of his or her paycheck.

“I spent a lot of time organizing the drivers’ schedules. In order to keep route errors down, I placed drivers only on routes that were familiar to them,” notes McMahon. “I wanted to ensure that our drivers could focus on driving safely to their destinations instead of having to worry about looking down at a map or getting lost. ”

So, the company began searching for a solution that would track orders more efficiently and make deliveries faster, as well as minimize the time customers spent placing orders.

Solution

McMahon Cartage selected an integrator of wireless, bar code and mobile solutions, to establish an online ordering system for scheduling delivery to gas stations. With Digital Fuel Solutions, the Web-based program developed by McMahon Carthage, delivery process time has been cut in half by allowing customers and distributors to order their gas online. The online orders are then given directly to the drivers via a Motorola® handheld device. After the driver delivers the gasoline, he prints a receipt using a Zebra® printer, eliminating errors and illegible writing.

Zebra RW 420 Takes the Cake in Head-to-Head Printer Comparison at Tastykake

About Tastykake

In 1914, a baker and egg salesman decided to join together to produce baked goods with the freshest ingredients. When the baker’s wife deemed the results of their efforts “tasty,” Tastykake was born. Now, the Philadelphia-based company sells more than $250 million worth of cakes and pies annually across the East Coast.

Challenge

With nearly 500 delivery routes, Tastykake brings fresh baked goods to hundreds of stores every day. The faster that drivers can restock each location, the more stops they can make in a day.

Drivers use Motorola® MC9000 handheld mobile computers to log the inventory coming off and onto store shelves. As they bring in new products, they print out invoices for each store on printers back in their trucks.

In an effort to improve efficiency, reduce costs, and add new capabilities, Tastykake began looking at new mobile printers.