Start Now

See what your business can do. Start with a free personalized assessment from our experts.

See what your business can do. Start with a free personalized assessment from our experts.

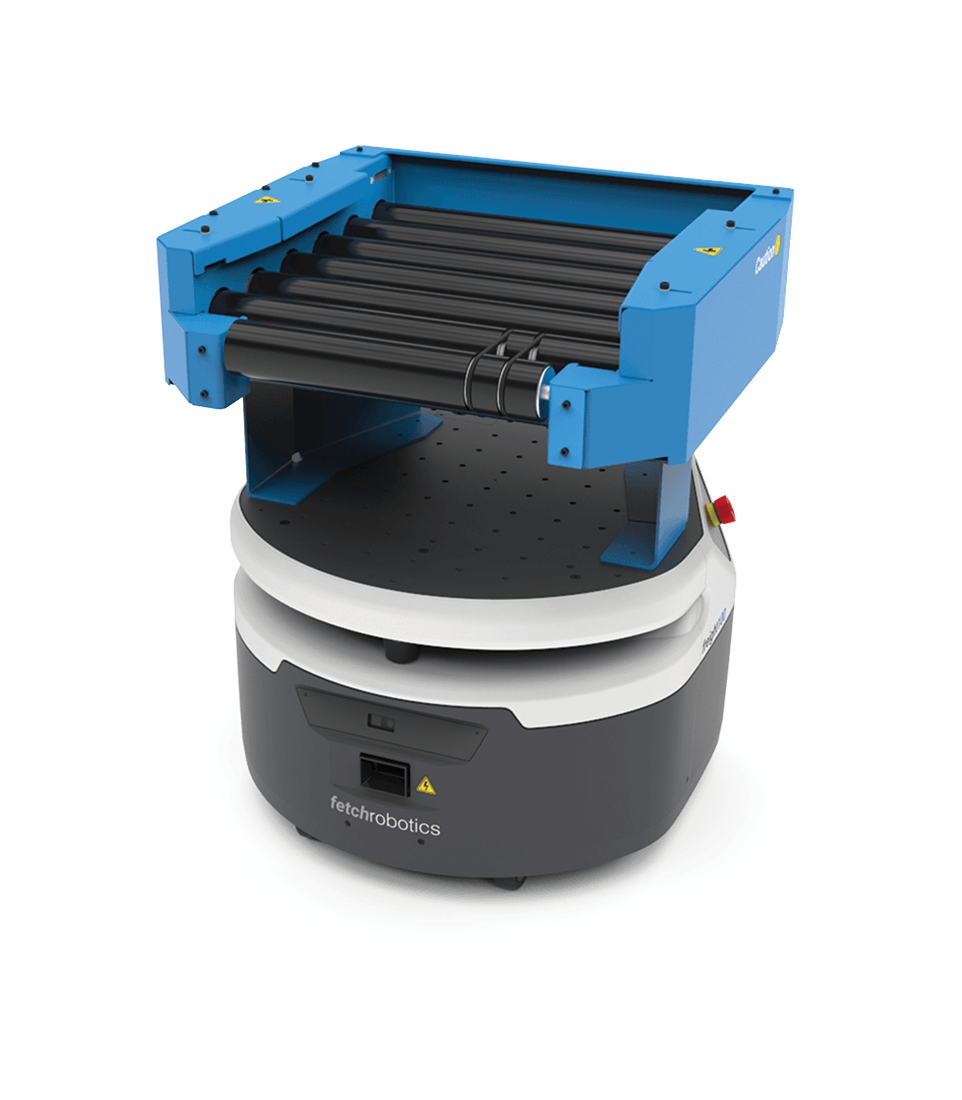

For years, conveyor systems have significantly enhanced industrial productivity; nevertheless, these fixed assets are difficult to adjust to today’s ever-changing material transport requirements. In conveyor-driven applications, the Fetch RollerTop solution promotes flexibility and automation. With both adjustable height and autonomous navigation, RollerTops can navigate themselves to conveyor and/or ASRS ends to load and unload totes and bins, allowing your personnel to focus on activities that need human decision making rather than loading and unloading manually.