Start Now

See what your business can do. Start with a free personalized assessment from our experts.

Thank You!

One of our experts will get in touch with you shortly.

See what your business can do. Start with a free personalized assessment from our experts.

One of our experts will get in touch with you shortly.

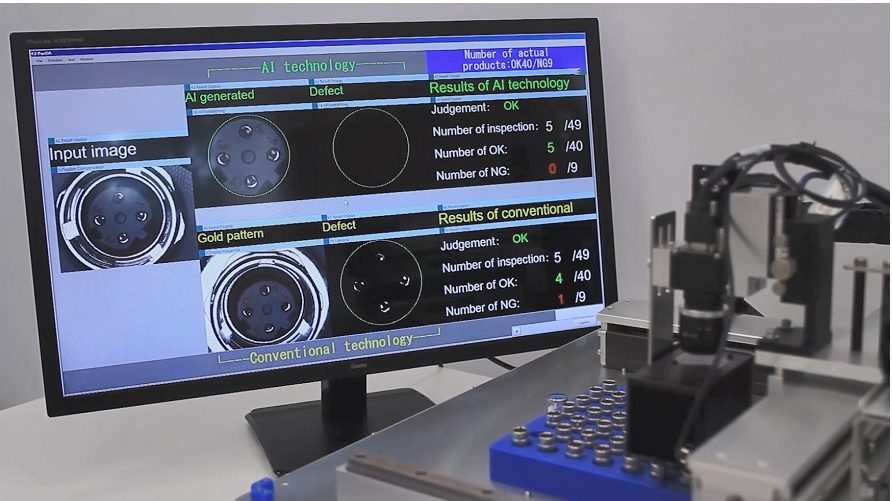

AI-powered, high definition vision technology identifies defects, variations, and inconsistencies on the production line with the expertise of a human inspector.

Defects and inconsistencies on the production line are easy for skilled human inspectors to spot. More often, experienced inspectors are looking for expected variances (slight cosmetic scratch or extra twist of a cap). But the list of qualified inspectors is shrinking despite record demand. This makes production costs difficult to forecast and manage.

Recommending and procuring the best vision cameras, monitors, and setups from our strategic partners is the easy part. We also integrate, configure, and install vision systems based on your specific production line requirements.