Five Things to Know Before Choosing an Embedded Data Acquisition Device

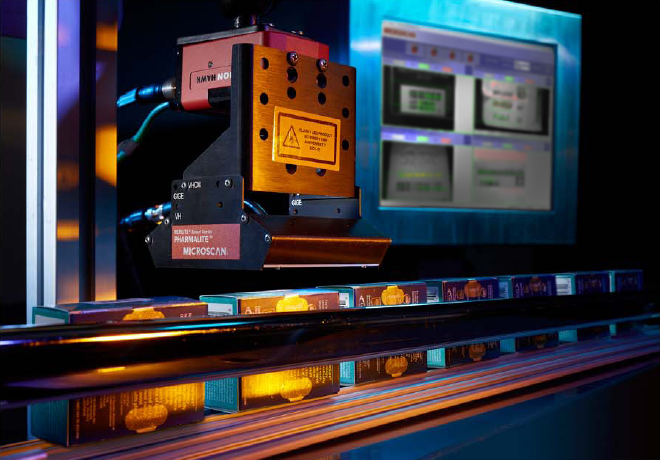

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

- Barcode Type and Orientation

- Inspection Requirements

- Application Speed

- Integration Space

- Data Communication Needs

6 Advantages of Ethernet Connectivity for Automated Scanning Applications

When managing the commonly high speeds involved with automated barcode scanning and vision environments, it’s crucial that your barcode readers can communicate data at the rates that the system and environment require. The type of interface you decide to use on your devices can help or hinder production. Most scanner offer options for RS-232 serial and USB connectivity but Ethernet offers distinct advantages for optimizing efficiency in automated systems.

- Faster data speeds – Ethernet connections offer high-speed data transfer that won’t limit production.

- Unlimited connections to the PC – With several independent Ethernet connections, PCs can manage multiple tasks in parallel for optimal productivity.

- Unlimited distance from the PC – Span greater physical distances without losing data speed and move or centralize PCs away from the production floor.

- Remote device management – Control devices anywhere there is a network connection and troubleshoot systems without leaving the office.

- Standardized cables – Common connectivity with all Ethernet equipment for no-hassle networking.

- Easy integration to MES and ERP – Ethernet-based MES and ERP systems pair naturally with Ethernet devices saving integration time and equipment.

Microscans Vision MINI Xi Now Supports EtherNet/IP

Microscan has announced the availability of EtherNet/IP communication on its ultra-compact machine vision smart camera, Vision MINI Xi. One of several cameras in Microscan’s award-winning AutoVISION machine vision product suite, the Vision MINI Xi offers a complete machine vision tool set for high-speed identification, inspection, and other automated tasks with the optimal size and shape for space-constrained machines.

With the release of the Vision MINI Xi Smart Camera in March, Microscan introduced industrial Ethernet TCP/IP to its miniature smart camera line, enabling integration with machines designed for Ethernet connectivity. With the release of AutoVISION 3.0.2 software, the Vision MINI Xi now supports communication via EtherNet/IP for use in industrial environments.