Star’s mPOP Now Integrated with Many Point of Sale Applications

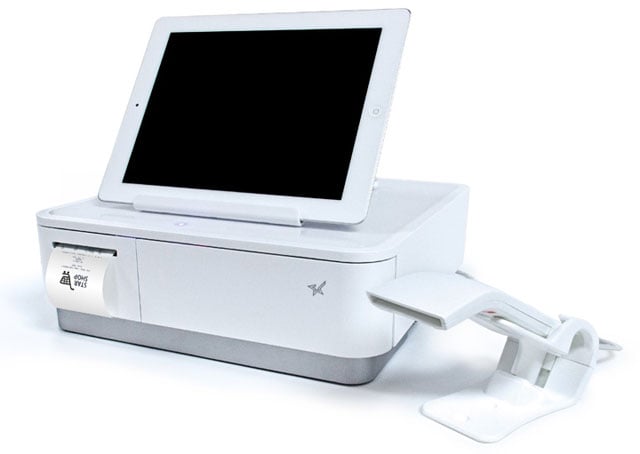

With Star’s latest release of its mPOP, Mobile Point of Purchase Solution, the first dedicated hybrid peripheral for tablet and mobile device based POS systems, industry leading POS software providers have shown keen interest in integrating this solution into their offering.

With Star’s latest release of its mPOP, Mobile Point of Purchase Solution, the first dedicated hybrid peripheral for tablet and mobile device based POS systems, industry leading POS software providers have shown keen interest in integrating this solution into their offering.

This compact and sleek ‘printer and cash drawer combined’ peripheral is the perfect solution for many retailers who are embracing the new era of electronic payment. Less cash usage allows smaller peripherals, like the mPOP, to be used at many stores’ point of sale.

Xplore’s New Camera Software for Bobcat and XC6 Rugged Tablets

Xplore Technologies has announced their new Xplore xCapture Pro camera software for their Bobcat and XC6 Windows-based tablets. The new camera software provides end users with photo editing, geo tagging and enhanced barcode scanning functionality. The addition of xCapture Pro as an integrated tool for the Bobcat and XC6 reduces the need for additional devices in the field and offers functionality to enhance the productivity of mobile workforces.

Xplore xCapture Pro is an ideal enterprise solution for field service, asset management, inventory management or occasional scanning of barcodes. The software is also beneficial for users who may need to know the time and location for when and where a photo was taken, such as a field service technician or insurance adjustor who wants to document an event or condition. They can also use the software to simply edit a photo or make notes on the image.

Datalogic Mobile Devices Are Now MCL Certified

Datalogic has been recognized as a certified device manufacturer by MCL Technologies, a leading provider of high-productivity software solutions that boost the development, deployment and management of enterprise mobile applications and devices.

Datalogic’s Memor X3, Skorpio X3 and Lynx mobile devices are now certified to run MCL v4 and the MCL Mobility Platform, after undergoing a thorough testing process. This certification enables channel partners to develop solutions for Datalogic mobile devices using MCL’s rapid application development environment. MCL will also provide direct maintenance and support to Datalogic partners.

Barcode Warehouse Management Software

Barcode warehouse management software is used to control the movement and storage of products or goods within a warehouse and process the associated transactions including, but not limited to, shipping, receiving, put away and picking through the use of barcode automatic identification and data capture (AIDC) technology.

Warehouse management systems manage the following core functions:

- Receiving – The ability to properly handle a shipment when it arrives. This process can be individualized to each warehouse or product type. In some cases, goods are not received into a facility, but rather cross-docked, which is a logistics procedure where products from a supplier or manufacturing plant are distributed directly to a customer or retail chain with marginal to no handling or storage time. Cross docking takes place in a distribution docking terminal; usually consisting of trucks and dock doors on two (inbound and outbound) sides with minimal storage space. The name ‘cross docking’ explains the process of receiving products through an inbound dock and then transferring them across the dock to the outbound transportation dock.

- Put Away – Put-away is normally thought of as the process of moving received inventory from the dock, kitting area, or production department to a storage bin. The put-away process is also used to relocate inventory within the warehouse and to replenish dedicated storage bins with inventory from a reserve storage bin. Any time inventory is being placed in a storage bin it is being put away. System directed put-away is when the WMS chooses the destination storage bin rather than the operator.

- Inventory – Inventory Technology refers to the supervision of supply, storage and accessibility of items in order to ensure an adequate supply without excessive oversupply. It also helps companies keep lost sales to a minimum by having enough stock on hand to meet demand. The inventory can be real-time or in the form of a cycle count, which is an audit procedure designed to verify the inventory accuracy for a small subset of inventory in a specific location on a specific day, thus providing an ongoing measure of inventory accuracy.

- Picking – Picking consists of taking and collecting articles in a specified quantity before shipment to satisfy a customer’s order. The following are different types of picking:

- Piece Picking (or Pick to Part) – Order pickets move to collect the products necessary for one order.

- Zone Picking – Each order picker is assigned to one specific zone and will only realize order picking within this zone.

- Wave Picking – Order picker moves to collect the products necessary for several orders.

- Sorting Systems Method – No movement of the order picker, as the products are brought to picker by an automatic system.

- Pick to Box Method – No movement of the order picker, as the picking area is organized so that there are a number of picking stations connected by a conveyor. The order picker fills the box with the products from his station and the box moves to the other picking stations until he customer order is complete.

- Packing – Packing occurs after the picking process and entails prepping a product or good for shipment by re-packaging, affixing with a shipping label, including an invoice and staging in preparation for shipment. Additionally, for certain goods or customers, there may be the requirement for kit building.

- Shipping – Shipping entails the delivery of the right product or good to the right customer or location using the right method of shipment, all while minimizing the cost. If a customer is doing their own delivery, incorporating proof of delivery allows for more accurate information and quicker confirmation to the customer. Furthermore, our software has the ability to integrate shipment tracking for customers.

Continue reading »

Barcode Inventory Management Software

Barcode inventory management software is used to supervise the supply, storage and accessibility of items in order to ensure an adequate supply without excessive oversupply through the use of barcode automatic identification and data capture (AIDC) technology.

Inventory systems consist of the following core components:

- Inventory Software – Software is the backbone of any system and will determine what features and options are available. When choosing inventory software you want to consider reporting detail and whether or not the software supports batch or real-time updates, as well as whether it needs to be integrated with an ERP system. Lastly, you want to determine whether a premise or cloud-based software is more ideal for your business.

- Mobile Computer – Inventory goods are located in different “bins” throughout a business. A mobile device allows you to have all the information you need to make decisions on when, where and how much to re-order.

- Barcode Printer – Inventory come in all shapes, sizes and quantities. Barcode printers are designed to print labels to meet every business size and print volume.

- Consumables – All inventory goods need a unique identifier on them to be properly tracked. Barcodes are the easiest and most cost effective option, while being capable of meeting environmental and regulatory requirements.

When evaluating barcode inventory management software, it is best to consider a cloud-based inventory management solution. Some of the benefits of cloud-based software include reduced capital expenditures, painless and cost-free software updates, lowered IT costs (i.e. no need to house multiple servers) and improved accessibility to the data through the Internet.

If you’re looking for a cloud-based barcode inventory management software that can fulfill all of your inventory requirements, look no further than BarcodesInc’s topShelf. TopShelf is an inventory, warehouse management, route accounting, asset tracking and online ordering application that caters to small up to enterprise-sized businesses. Our barcode inventory management software has the ability to integrate with ERP systems (SAP, Oracle, etc.), Accounting systems (Sage, Quickbooks, etc.), CRM systems (Salesforce, Microsoft Dynamics, etc.) and eCommerce Systems (Channel Advisor, Shopify, Amazon).

To request a demo of topShelf or request more information on our barcode inventory management software, contact us at Barcodes Inc.

Cipherlab 8600 Series New Software Suite

Easy Development, Fast Deployment, Efficient Operation

The CipherLab 8600 mobile computer comes equipped with value-added software for simple and easy development. Forge Application Generator is designed for non-programmers to create applications without writing any codes, and it bundles with Remote Console which helps you to manage multiple mobile devices on a PC. Text Browser allows you to run web-based applications via internet. Mirror Terminal Emulator can extend complex mainframe applications to your 8600 handheld terminal. Furthermore, C Complier and BASIC Complier can be utilized to develop applications with more complexity.

For assistance finding the right CipherLab mobile device for your needs, contact us at BarcodesInc.

Datamax-O’Neil Introduces the NETira Software Suite of Printer Tools

Unlock the power of your printers with the NETira suite of software tools designed to expand and enhance the performance of your Datamax-O’Neil printers. NETira offers users the ability to set-up your printer, design custom labels or manage an entire network of printers with the touch of a few buttons. NETira reduces setup time and provides the tools to effectively utilize all of your printer’s capabilities.

Thoroughly tested and certified by Datamax-O’Neil technicians, NETira provides users with easy-to-use software that presents a consistent look and feel for navigation. Whether it’s a single printer or part of a networked environment, NETira applications reduce setup time and provide users with the tools to effectively utilize all of their printers’ capabilities. The NETira suite includes:

Zebra Technologies Introduces ZMotif CardStudio Card Design Software

Classic, Standard or Professional CardStudio Software Offered for Basic to Advanced Card Design and Printing

Zebra Technologies, announces the release of its ZMotif CardStudio card design and issuance software suite this week. CardStudio is a Zebra card design software application for intuitive design, encoding and printing of simple to complex design cards. CardStudio is available now, in 11 different languages worldwide.

Ideal for a variety of markets, CardStudio is easy to use right out-of-the box. Users are able to design cards for access control, gift cards, loyalty and club cards, school identification and library cards, and visitor badges. This software is optimised for all Zebra card printers including: direct-to-card, retransfer, current and legacy models, and contains many new features and benefits for anyone looking at designing and printing cards. CardStudio’s Direct-to-Printer (D2P) technology optimises print quality and performance by providing advanced print control functionality from card design elements directly to the printer. New capabilities and features such as new software only license manager, and D2P print technology demonstrate Zebra’s commitment to deliver and innovate productivity software for ID cards across a wide range of industries and hardware/software solutions.