1D vs 2D Barcodes Explained

When it comes to tracking anything from basic inventory to patient data, choosing the right type of barcode can be the difference in how effective your system works. Everyone is familiar with the standard picket fence 1D linear barcodes but more and more applications are migrating to 2D barcodes. Both types of codes have their benefits and advantages and our specialists at Barcodes, Inc can help you determine which is the best fit for your needs.

Five Things to Know Before Choosing an Embedded Data Acquisition Device

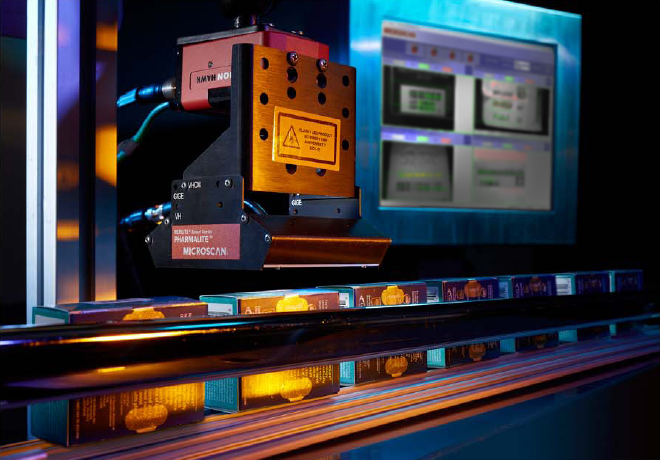

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

Successful data acquisition for barcode reading or part inspection depends on the ability of the data acquisition device, such as a barcode reader or machine vision camera, to function at peak performance within the restrictions of the application. In applications where barcode reading or machine vision inspection processes are embedded inside of equipment, limited integration space puts a unique set of restrictions on how a device can be installed, not to mention demands on the size and capabilities of the device itself. Before installation, it is important to choose a device with optimal specifications to ensure inspections can be done accurately and consistently throughout the life of the machine. This post outlines the five things an engineer should know before choosing a data acquisition device for embedding into equipment, including:

- Barcode Type and Orientation

- Inspection Requirements

- Application Speed

- Integration Space

- Data Communication Needs

Evaluating Barcode Reading Technologies: Laser vs. Imager

Choosing the right barcode reading technology is fundamental to achieving optimal performance from a data collection solution. As new symbologies and technologies are developed, the choices are more varied than ever. There has been much debate on the merits of laser-based and camera-based barcode readers, and in fact, some have asserted that only image-based readers should be considered for new automation applications.

Should laser barcode scanners be considered “obsolete” technology and are imagers (camera-based readers) the only viable technology for today’s applications? While imagers have seen increased use due to the growing adoption of 2D symbols such as Data Matrix, laser scanners still set the standard for accurate, high speed barcode reading in many applications. The optimal barcode reading solution will be dictated by the specific requirements of an application.

CipherLab Launches 1600 Series Laser Scanner for Dependable Reading Function

1662 Laser Barcode Scanner is designed to enhance dependability in the field mobility and outdoor applications with the new reader option.

1662 Laser Barcode Scanner is designed to enhance dependability in the field mobility and outdoor applications with the new reader option.

CipherLab, a leading innovator in Automatic Identification and Data Capture (AIDC) has delivered a new scanner – 1662 laser scanner to the 1600 series of pocket-sized scanners. Easily to be carried around, this scanner is also equipped with a laser reader to better assist your field staffs when capturing barcodes under the bright sunlight. Additionally, the long lasting battery life of 1662 laser scanner makes it a must-have tool for your mobile staffs.

Imaging Moves Into the Mainstream

Why 2D Imagers are Surpassing Laser Scanners for Bar Code Applications

Why 2D Imagers are Surpassing Laser Scanners for Bar Code Applications

Misperceptions about 2D imagers are changing fast, which is why 2D imagers are the fastest-growing category of bar code readers. Only a few years ago 2D imagers were (wrongly) considered a niche technology mostly used for reading 2D bar codes. Now they are becoming the technology of choice for most bar code applications, and lasers are on the way to becoming a niche technology. The reasons: 2D imagers are as fast or faster than laser scanners, can read all the same bar codes as lasers plus 2D symbols that lasers can’t, and can do much more.

Not only can 2D imagers read more bar codes than lasers – including QR Codes, Data Matrix and other popular 2D symbols – they can also do more than read bar codes. Imagers can take digital pictures, shoot video, capture customer signatures, scan documents and even process the scanned data. These capabilities, which are outlined in the graphic below, enable new business processes that are not possible with older-generation technology. In an era where workers are tasked with doing more – collecting more information, providing more documentation, being more productive, etc. – 2D imagers provide more flexibility.

2D imaging technology gives businesses the two things they need most from their bar code readers: outstanding performance in today’s applications, and investment protection to meet future needs. This white paper is a guide to 2D bar code imaging technology, including an overview of capabilities and how 2D imagers perform in traditional applications, the beneficial new business processes that imaging enables, and the advantages 2D imaging provides compared to laser scanners.