Customize Your Imager’s Scanning Using Honeywell’s Centering, Aimer Delay, and CodeGate Features

With all imager based scanners, the default decode mode is the full area of the decode window, so it will decode whatever barcode it sees first. This makes it difficult sometimes to target a specific barcode when the barcodes are close together. We can help using the below features:

With all imager based scanners, the default decode mode is the full area of the decode window, so it will decode whatever barcode it sees first. This makes it difficult sometimes to target a specific barcode when the barcodes are close together. We can help using the below features:

- Centering(AKA pick list mode or center decode): This feature narrows the scanner’s field of view to make sure the scanner reads only those barcodes intended by the operator.

- Aimer Delay: Turns on the aimer for a split second before the scanner scans. This allows time for the operator to position the scanner over the specific barcode before the barcode is scanned.

- CodeGate: Similar to Aimer Delay except the aiming beam is on all the time, but scanner won’t scan until scanner button is pressed or specific time passes.

Honeywell: The Smarter Choice for Thermal Printing Supplies

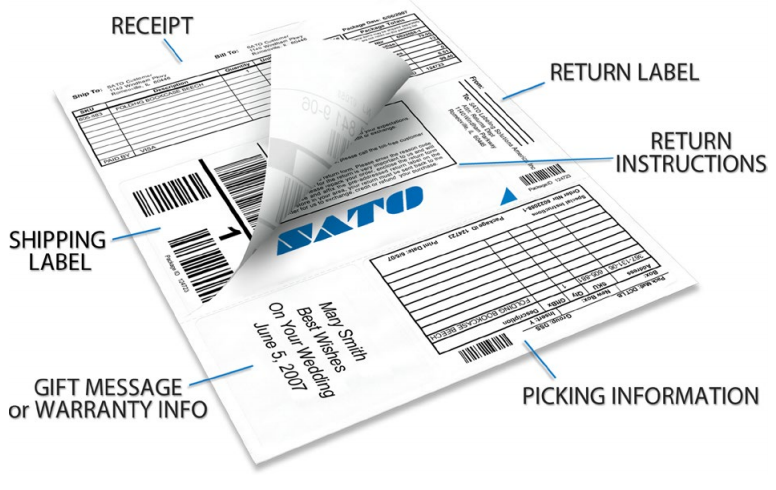

Having some of the industries most popular and capable label printers goes hand-in-hand with premium supplies for them. From simple direct thermal shipping labels to rugged polyester labels for outdoor use, Honeywell has supplies to handle the requirements of the most demanding environments.

Having some of the industries most popular and capable label printers goes hand-in-hand with premium supplies for them. From simple direct thermal shipping labels to rugged polyester labels for outdoor use, Honeywell has supplies to handle the requirements of the most demanding environments.

Honeywell genuine labels, RFID tags, receipts and ribbons support a broad range of barcode printing applications in mild to harsh environments. While a wide variety of these are offered as take-from-stock products for fast delivery, Honeywell will also customize the label material, configuration, size or any other feature to meet even the most challenging environment. Whether an off-the-shelf or custom solution, Honeywell has media solutions to meet any unique requirement.

To learn more about Honeywell’s selection of labels, receipt paper, wristbands, and RFID tags, contact one of our media specialists at Barcodes Inc.

Using Serialization for Unique Identifiers in Seagull Scientific BarTender

From WIP (work in progress) to the food and pharmaceutical industries, tracking items with unique serialized barcode labels is necessary to accurately and easily locate products in cases of a recall, customer alerts, expiration management, and counterfeit prevention. Proper serialization allows any business to know exactly where a problem starts and ends since each item has a unique, non-repeated barcode to identify it.

From WIP (work in progress) to the food and pharmaceutical industries, tracking items with unique serialized barcode labels is necessary to accurately and easily locate products in cases of a recall, customer alerts, expiration management, and counterfeit prevention. Proper serialization allows any business to know exactly where a problem starts and ends since each item has a unique, non-repeated barcode to identify it.

One of the many advantages of Seagull Scientific’s BarTender label software is fully integrated serialization capabilities. BarTender has multiple types of serialization options and once you have a data source configured, the value will automatically increment or decrement with every printed label.

For step-by-step guidance in how to setup serialization in BarTender download this convenient white paper

Zebra Labels for Any Application

Label printing isn’t rocket science by any means but knowing what label to use for your specific application can be challenge at first. Zebra has been the leading manufacturer of printers and labels with a wide range of offerings to meet the needs of any environment from very short term temporary shipping labels to rugged, outdoor asset labeling.

Label printing isn’t rocket science by any means but knowing what label to use for your specific application can be challenge at first. Zebra has been the leading manufacturer of printers and labels with a wide range of offerings to meet the needs of any environment from very short term temporary shipping labels to rugged, outdoor asset labeling.

Following these simple guidelines it’ll be easy to determine which type of label you need and the most suitable Zebra options.

Label Adhesive Breakdown

Label come in many sizes, shapes and materials. Labels also have several options of adhesives. Although size and material is important, the type of adhesive a label contains can be critical to the success of the label in the desired application. Consider the following choices when selecting the proper label:

Label come in many sizes, shapes and materials. Labels also have several options of adhesives. Although size and material is important, the type of adhesive a label contains can be critical to the success of the label in the desired application. Consider the following choices when selecting the proper label:

- Removable Labels: These labels are designed to be removed from the surface they are applied to. The labels will adhere to most dry, clean surfaces. The benefit of this label is that the label can be completely removed from the surface without damage to the surface or excess adhesive residue/ label flaking during the removal process.

- Permanent Labels: These labels are designed to be non-removable. Ideal for application where the label needs to withstand a long amount of time on a surface and where the label cannot be removed with out being damaged. Shipping a box, warehouse signage or asset tracking are a few applications where a label with a permanent adhesive would work best.

- High-Tack Labels: These labels are designed to also be non-removable. However, the difference is that these labels can withstand higher levels of abrasion, outdoor environments (water and UV resistant) and locations where the label may come in contact with chemicals.

- All-Temp Labels: These labels can be used in several different applications where the labels may be moved from a hot to cold location. Moving inventory from a cold climate to a hot climate is an ideal application for this type of label. These labels are not intended for extremely high temperature applications.

- High-Temp Labels: These labels are designed to be used in environments or applications that may expose the label to extremely high temperatures.

Choosing the proper adhesive is crucial to the success of the label. Reach out to your knowledgeable BarcodesInc sale representative for more information on which label is correct for your application.

Zebra Labels for Indirect Food Contact FDA 175.105

Many food packaging and repackaging businesses have a need to find a packaging label that has an adhesive suitable for indirect food contact. Most importantly these business need a labeling solution that meets Food and Drug Administration (FDA) guidelines for indirect food contact. Indirect food contact is defined as a substance that may come into interaction with food as part of packaging or processing equipment, but are not intentionally added directly to the food. Using a label that doesn’t meet food contact requirements can potentially lead to contaminated food, product returns and fines for having unapproved adhesives used in a food application.

Many food packaging and repackaging businesses have a need to find a packaging label that has an adhesive suitable for indirect food contact. Most importantly these business need a labeling solution that meets Food and Drug Administration (FDA) guidelines for indirect food contact. Indirect food contact is defined as a substance that may come into interaction with food as part of packaging or processing equipment, but are not intentionally added directly to the food. Using a label that doesn’t meet food contact requirements can potentially lead to contaminated food, product returns and fines for having unapproved adhesives used in a food application.

Zebra manufactures several sizes and types of labels that have an adhesive formulation developed to meet FDA regulation 175.105, indirect food contact (see this list for FDA approved labels). These labels are approved to be used for indirect contact food applications such as, label food in a retail location to large scale packaging of food from a manufacturing facility.

Avoid the hassle and expense of using non-food approved labels by introducing Zebra labels, which meet FDA regulation 175.105 for indirect food contact, into your food application today.

Contact your dedicated BarcodesInc representative today, for more information.

How Do I Know What Barcode Label I Have?

Barcode labels come in a variety of types and materials to meet the needs of a range of applications. From a temporary shipping label to a rugged asset tag that needs to endure the challenges of outdoor use, there are labels that can meet these needs.

come in a variety of types and materials to meet the needs of a range of applications. From a temporary shipping label to a rugged asset tag that needs to endure the challenges of outdoor use, there are labels that can meet these needs.

Knowing what type of label you are using is almost impossible to tell from just looking at it but there are a few key tests you can conduct to figure out what type and material your label is. Following these steps you can be assured you order the same label your application needs.

1. Try to tear the label in half

If you can tear the label in half we know right away that it’s a paper stock as opposed to a synthetic material like polypropylene or polyester. Synthetic materials may stretch and deform a bit but will not be tear-able by hand.

Continue reading »

Label Features to Solve Common Retail Problems

Most people don’t realize how many choices there are when it comes to designing a label or tag. Even the simplest of features can be cost-effective and can make a big impact in improving the overall retail store environment from back-office to customer experience.This white paper focuses on several features that can reduce shrink and improve customer satisfaction.

Most people don’t realize how many choices there are when it comes to designing a label or tag. Even the simplest of features can be cost-effective and can make a big impact in improving the overall retail store environment from back-office to customer experience.This white paper focuses on several features that can reduce shrink and improve customer satisfaction.

Shrink Management

To cut back on stolen merchandise, retailers are often required to implement expensive solutions like EAS (Electronic Article Surveillance) systems and trained security. However, there are less expense ways to deter theft.

Tech Tips: Sensor Error Fix for Sato CLe Series Printers

Sensor Error – Common Causes/Solutions for the Sato CL408e and CL412e

Cause: Incorrect sensor type selected on the printer and/or in the software/driver settings.

Solution: Select the appropriate sensor type using DSW2-2 on the printer.

Cause: Dirty or obstructed sensor and/or media loaded improperly.

Solution: Make sure sensor is free from obstructions and blow out with compressed air, then refer to Label Routing diagrams on the printer to properly load media.

For assistance with any Sato product, contact us at Barcodes Inc.

Labeling in Freezer Applications

From food packaging to laboratory applications, BarcodesInc offers a variety of freezer grade labels specifically engineered to adhere to frozen surfaces. These labels are developed to work with both thermal transfer and direct thermal technologies in a wide range of label printers. They feature excellent adhesion to a variety of frozen packaging materials and other substrates over a wide temperature range. Likewise, they are also well suited for applications in moist, damp environments.

From food packaging to laboratory applications, BarcodesInc offers a variety of freezer grade labels specifically engineered to adhere to frozen surfaces. These labels are developed to work with both thermal transfer and direct thermal technologies in a wide range of label printers. They feature excellent adhesion to a variety of frozen packaging materials and other substrates over a wide temperature range. Likewise, they are also well suited for applications in moist, damp environments.

Are your labels for frozen packages peeling, warping maybe even wrinkling? Labeling frozen packages can be tricky because all labels are not created equal. Different cold and freezer environments require different types of labels. We have the solution for you!