Barcoding News

Data tracking news, product updates, tips, and more

Star’s New Wi-Fi Power Pack

To meet the growing demand for wireless POS solutions, Star Micronics has introduced its WiFi Power Pack. The WiFi Power Pack is designed to make any Star LAN interface printer “wireless” in a cost effective way without a lot of messy cables. This, in turn, enables the Star printer using the WiFi Power Pack to connect with tablets, smart phones and other portable electronic wireless devices.

To meet the growing demand for wireless POS solutions, Star Micronics has introduced its WiFi Power Pack. The WiFi Power Pack is designed to make any Star LAN interface printer “wireless” in a cost effective way without a lot of messy cables. This, in turn, enables the Star printer using the WiFi Power Pack to connect with tablets, smart phones and other portable electronic wireless devices.

The included wireless router conveniently shares the wireless connection around small to medium size businesses at 150Mbps. The WiFi Power Pack’s tiny size makes it ideal for installation and is powerful enough to satisfy almost any basic wireless application requirement.

Trade-In and Trade-Up to a New Intermec Printer!

Intermec’s popular trade-in program is back!

This year, trade in a competitive or Intermec pre-owned thermal printer and receive a rebate up to $525 off the purchase of a new Intermec printer.

Special for this year, you can also trade in an Intermec 3400/3440 series printer and receive up to an additional $100 bonus rebate on the purchase of a new Intermec PM43/PM43c series printer, resulting in a total savings of $400! For those looking to upgrade to the industry’s most rugged, reliable and smart printing solution—the time has never been better. Take your savings even further by adding Genuine Intermec Media and Services!

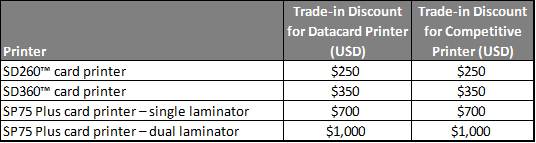

Datacard SmartTrade Promotion

There has never been a better time to trade in your old printer and receive great discounts on all current Datacard printers. Now through march 15, 2013, enjoy the following incentive to replace competitors’ printers or upgrade existing Datacard printers and save up to $1,000. Program includes SD260, SD360, and SP75 Plus.

In addition to the rebate, Barcodes Inc can offer a variety of Datacard ribbons, software and ID cards for all of the models listed above. These items are in stock and ready to ship. Call us to find out how we can help solve your ID needs.

CipherLab’s Newest Linear Imager Scanner

CipherLab has announced the introduction of the newest addition to the 1600 series – 1663 linear imager scanner. This pocket-sized scanner is equipped with IP42 rating and 1.5 m drop resistance that ensures its ruggedness and reliability. Moreover, it includes outstanding capability to read high density barcodes up to 3 mil resolution.

CipherLab has announced the introduction of the newest addition to the 1600 series – 1663 linear imager scanner. This pocket-sized scanner is equipped with IP42 rating and 1.5 m drop resistance that ensures its ruggedness and reliability. Moreover, it includes outstanding capability to read high density barcodes up to 3 mil resolution.

1663 linear imager scanner includes a 20 m Bluetooth working range which can pair with your PDAs or Smartphones and enlarge the working scope from the host. It also allows users to increase productivity by offering an ample 4 MB memory, storing up to 240,000 scans under batch mode. Users do not have to worry about working out of Bluetooth range with its 10 KB buffer memory which stores about 600 scans. You will also enjoy Time Stamp which can accurately keep track of the exact time and date of every barcode read for better data analysis.

Hazmat Container Labeling

BarcodesInc and Datamax-O’Neil are proud to showcase a new innovative labeling solution: ChemShield Drum Labeling Solutions.

BarcodesInc and Datamax-O’Neil are proud to showcase a new innovative labeling solution: ChemShield Drum Labeling Solutions.

Safety. Efficiency. Compliance. We understand the importance of these three words as they relate to the needs of Hazmat container labeling. With this understanding comes a commitment to provide label products that fulfill these needs.

We offer a comprehensive line of Drum Labeling Solutions that work with the most challenging of environments and regulations. We stand by the motto “Rest- Assured, Performance Guaranteed.”

For more information on all our label solutions, contact us at BarcodesInc

Join the M2M Revolution with the Benefits of Barcodes

VDC Research, a leading Auto-ID and Barcode research firm, is hosting a webinar on February 26th on the benefits and impact of using barcodes within the ever expanding use of mobile to mobile communications. As more business move away from fixed to mobile computing solutions, manufacturers of barcode scanning and printing solutions have the potential to be at the forefront of this ongoing M2M evolution.

VDC Research, a leading Auto-ID and Barcode research firm, is hosting a webinar on February 26th on the benefits and impact of using barcodes within the ever expanding use of mobile to mobile communications. As more business move away from fixed to mobile computing solutions, manufacturers of barcode scanning and printing solutions have the potential to be at the forefront of this ongoing M2M evolution.

The 45 minute webinar will cover:

- The measurable benefits of incorporating barcoding into enterprise operations as companies invest in resources to build out their M2M connectivity and communications platform in support of applications throughout the extended supply chain.

- The impact that the changing nature of barcodes is having on how enterprises connect and communicate with their customers via smart devices – both professional and consumer-grade.

- The role that barcodes play in triggering seamless communication across channels, networks and organizational boundaries.

- How barcoding with M2M helps companies leverage actionable business intelligence and analytics across diverse vertical markets and installation environments.

- Why M2M and IoT (Internet of Things) should be an integral part of barcode technology vendors’ strategic and operational objectives and how they can get there before it is too late.

You can find more details and register for the Feb 26th session here.

Its Here! Introducing the Zebra ZXP Series 7 ID Card printer

Zebra recently announced the launch of their new foray into the ID card printer market, the ZXP Series 7 Printer. This new printer is built for performance, productivity, adaptability and cost efficiency, and will ultimately replace the legacy P330i, P430, P630i, and P640i.

Zebra recently announced the launch of their new foray into the ID card printer market, the ZXP Series 7 Printer. This new printer is built for performance, productivity, adaptability and cost efficiency, and will ultimately replace the legacy P330i, P430, P630i, and P640i.

The ZXP Series 7 printer is built to meet all the needs of today’s demanding business environments.

- Robust design that works out of the box in a wide range of environments and applications

- Generates near-photographic print quality and color depth using photo-print technology

- Edge-to-edge card printing

- Laminator ensures security of the cards and lengthens the life of the image

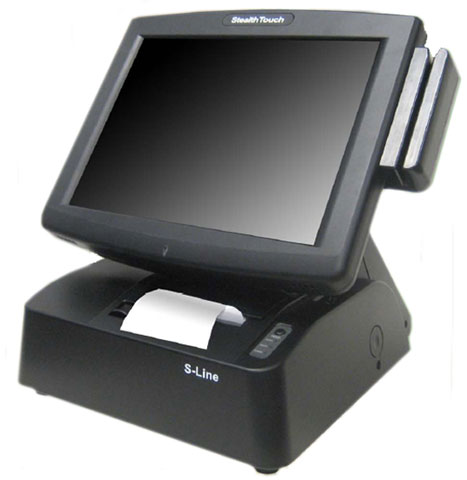

Pioneer POS Now Certified by Merchant Applications Inc

Pioneer POS has announced that the Pioneer POS Stealth S-Line with built in Epson printer, has been approved for use with Merchant Applications Inc. retail management software.

Scott Johnston, Director ISV/Channel at Pioneer said that “Merchant Applications RMS and Pioneer offer flexibility, dependability, and customer support that others can’t match. Customers can trust they are getting value from Merchant’s Windows based retail software.” Scott also added that, “We are extremely excited to announce the S-Line all-in-one terminal certification for use with Merchant Applications retail software, and I think that together they are really are the complete solution.”

CipherLab Releases the New CP60 Industrial Mobile Computer

CipherLab has announced the release of the CP60 industrial mobile computer. The CP60 is packed with flexible wireless communication options in 3.8G HSPA+, 802.11 a/b/g/n, and Bluetooth V2.1 with EDR. The CP60 goes one step further and provides 4G LTE option which allows you to transfer large amounts of data in a speedier time. Its embedded GPS/AGPS allows total navigational control.

Moreover, CP60 is armed with a 1GHz processor and multiple operating system options in Windows Embedded Handheld 6.5.3 and Windows CE 6.0 R3. It comes fully equipped with a large 4 GB flash memory and 512 MB SDRAM, which allows for extended storage of data and software. On top of all that, it provides versatile and accurate data capture with laser reader, long range laser reader, 2D imager and 5 megapixel autofocus camera. Your field agents are definitely ready to deliver a more efficient business operation.

Microscan Announces AutoVISION 2.0 – Simplified Machine Vision Software

Microscan announced the availability of AutoVISION 2.0, its latest generation of machine vision software for their Vision Mini and Vision Hawk products. AutoVISION 2.0 combines a simplified user interface with a powerful toolset for inspection, error proofing, and identification applications.

AutoVISION 2.0 maintains the same intuitive interface as the initial AutoVISION release, but provides additional capabilities, including Verification and OCV (Optical Character Verification) Tools to validate print quality, a Logic Tool for building pass/fail criteria, and support for automated job changeover. AutoVISION 2.0 also features Microscan LINK for easy connectivity to PLCs and other industrial control systems.