Barcoding News

Data tracking news, product updates, tips, and more

Zebra Printers Continue to Be Energy Star Compliant

Zebra products are designed to provide the lowest Total Cost of Ownership (TCO) to our customers, including the amount of energy our printers consume. ENERGY STAR is a U.S. Environmental Protection Agency (EPA) voluntary program that certifies products meeting higher standards of reduced energy consumption. Printers that are ENERGY STAR-qualified consume approximately 10% less energy than a standard product. We’re proud that many of our printers are ENERGY STAR-qualified.

Zebra products are designed to provide the lowest Total Cost of Ownership (TCO) to our customers, including the amount of energy our printers consume. ENERGY STAR is a U.S. Environmental Protection Agency (EPA) voluntary program that certifies products meeting higher standards of reduced energy consumption. Printers that are ENERGY STAR-qualified consume approximately 10% less energy than a standard product. We’re proud that many of our printers are ENERGY STAR-qualified.

As of Jan. 1, 2014, ENERGY STAR is changing its certification criteria and implementing Version 2 regulations. The majority of the Zebra printers that currently have ENERGY STAR certification will continue to be compliant with the new ENERGY STAR Version 2 regulations.

CipherLab’s 1600 Series: The Perfect Scanner for iOS and Android Devices

CipherLab 1600 series pocket-sized Bluetooth scanner helps you accomplish various tasks when pairing with different smart devices through Bluetooth connectivity. Smaller and lighter than a mobile phone, it is a handheld scanner which can easily fit in your pocket and carried around for required tasks wherever it takes.

Barcodes Help Provide The Complete History of Aomori Apples

The Aomori prefectural government and local apple farmers plan to introduce a barcode system that will allow customers to check the history of each apple they buy. The move was prompted by growing calls for safer food, particularly in foreign countries.

The Aomori prefectural government and local apple farmers plan to introduce a barcode system that will allow customers to check the history of each apple they buy. The move was prompted by growing calls for safer food, particularly in foreign countries.

Aomori Prefecture, a prime apple growing area in northern Japan, is seeking to expand the export of its apples to foreign markets. The new system will use the very common QR Code, a two-dimensional barcode. QR codes can be read by mobile phones, giving the customer information on where the apple came from and how it was cared for, such as how often pesticides were used, and even providing a photo and message from the farmer who grew the fruit. The data will be available in Japanese, Chinese and English.

TSL Offers New Accessory Option for the 1128 Bluetooth UHF RFID Reader

TSL has announced a new wrist mount and belt holster accessory for the 1128 Bluetooth UHF RFID Reader, facilitating fast, accurate and cost-effective tracking of products, assets and data in such applications as retail, logistics, warehousing and distribution.

TSL has announced a new wrist mount and belt holster accessory for the 1128 Bluetooth UHF RFID Reader, facilitating fast, accurate and cost-effective tracking of products, assets and data in such applications as retail, logistics, warehousing and distribution.

The 1128 Bluetooth UHF RFID Reader is designed to communicate wirelessly with a variety of Bluetooth-enabled mobile devices, including enterprise handhelds, consumer phones, touchscreen MP3 players, tablets and PCs. Using the new MC40 Wrist Mount and carrying the 1128 Bluetooth UHF RFID Reader in the Belt Holster, data can be captured and transmitted completely hands-free via automatic RFID scanning.

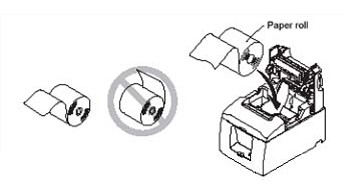

Tech Questions: My Star Thermal Printer Isn’t Printing

My Star thermal printer feeds paper but is not printing at all.

Answer

The cause could be that the paper is not thermal-coated or it was loaded upside down. To verify that the roll is thermal-coated, scratch the surface of the paper with a coin or nail. If the top coat shows a gray mark where the scratch was made, the paper was thermal-coated. Next, verify the thermal paper was loaded correctly and try printing again (see illustration).

For additional assistance with or finding the right Star printer for your needs, contact us at Barcodes Inc.

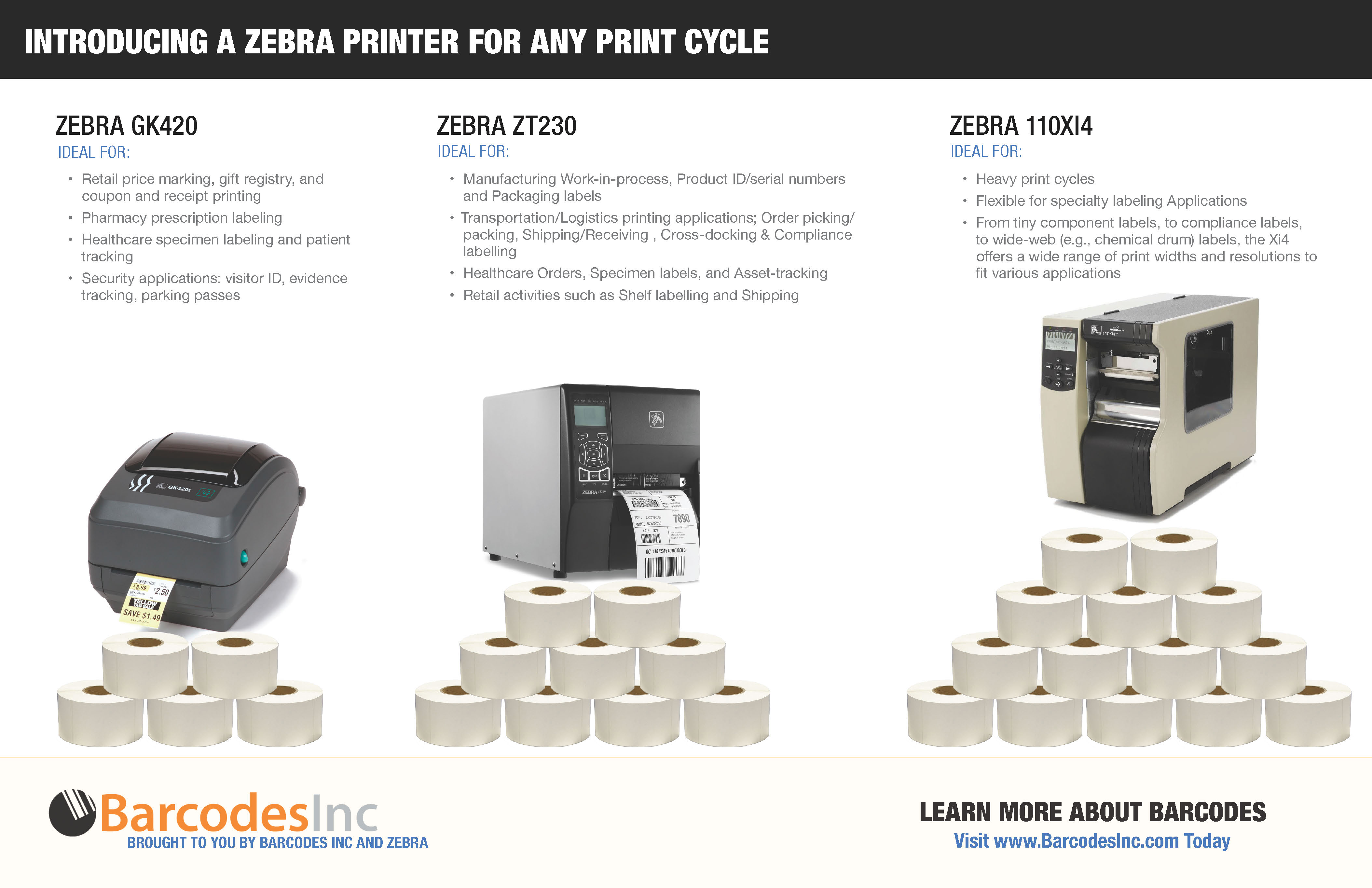

Zebra Printer Duty Cycle – Infographic

Barcode label printers come in variety of sizes and types depending on how fast and much they can print. Normally they get grouped into 3 main categories: desktop, tabletop, and heavy industrial. Outside of the obvious size difference between them, their overall print duty cycle varies quite a bit as well. The main concern when choosing the right size printer for your needs is considering the long term print volume you will be dealing with. Any printer can keep printing all day but the main issue will be how often you will have to reload media and replace common parts like your printhead and platen roller.

Barcode label printers come in variety of sizes and types depending on how fast and much they can print. Normally they get grouped into 3 main categories: desktop, tabletop, and heavy industrial. Outside of the obvious size difference between them, their overall print duty cycle varies quite a bit as well. The main concern when choosing the right size printer for your needs is considering the long term print volume you will be dealing with. Any printer can keep printing all day but the main issue will be how often you will have to reload media and replace common parts like your printhead and platen roller.

This infographic looks at Zebra’s most popular printers in each category and provides a breakdown of when and where they are best suited to be used.

For more assistance finding the right Zebra printer for your specific needs, contact us at Barcodes Inc.

Zebra’s Compact, Easy-to-Use UHF RFID Printer the ZD500R

The new ZD500R extends Zebra‘s broad range of RFID printers by adding UHF RFID printing and encoding to Zebra’s line of industry-leading compact thermal desktop printers. Designed for applications where space is at a premium, the ZD500R offers simple, one-touch printing and encoding, straightforward loading, and automatic RFID calibration, making it ideal for applications where technical support staff is limited, such as retail in-store exception tagging.

The printer supports both direct thermal and thermal transfer printing and is compatible with inlays from all leading suppliers. The ZD500R can be used with a variety of RFID labels and tags from small, item-level hang tags to large case and pallet labels. By encoding RFID inlays that are spaced closer together, the ZD500R enables lower media costs, less media waste and fewer roll changes.

SummerEyes Woodcrafts Serves Customers More Efficiently With Mobile POS and the Star TSP143LAN

SummerEyes Custom Woodcrafts is a small business that specializes in the creation of wood products for the home and garden. The owner of Summer Eyes, Ross MacKay, prides himself on his custom wood planter boxes, arbors, trellises and different types of nesting houses and feeders.

During the warmer months, Mr. MacKay and his staff attend many craft shows and farmers’ markets to showcase their wares. SummerEyes only accepted cash or check, but Mr. MacKay and his staff saw that it would be more convenient for customers to be able to pay with credit cards as well. He began to look for a mobile POS solution that would allow him to begin accepting credit cards, easily process payments and print a receipt.

Deutsche Post Deploys 55,000 Honeywell Dolphin 99EX Mobile Computers

Germany’s leading provider of post and parcel services Deutsche Post DHL is equipping its employees with 55,000 Honeywell Dolphin 99EX mobile computers. The devices will enable approximately 60,000 employees to track and trace millions of DHL parcels delivered each day across Germany, including more than seven million parcels during the peak holiday season.

More than 2,500 users from Deutsche Post DHL’s parcels division tested 11 different devices before choosing the Dolphin 99EX for offering the best combination of ergonomics, robustness, capacity, performance and ease of use. The device’s long battery life and ability to quickly photograph items to prove condition at the point of delivery were further factors.

Honeywell’s Remote MasterMind device management software will help to keep Deutsche Post’s drivers fully operational. The software makes an IT administrator’s job easier with the ability to manage all of the company’s mobile devices from a central system. Ensuring that each device has updated software and is properly configured reduces errors and prevents device downtime that can slow the driver. Initially the software is being used to manage all 55,000 devices across all of the company’s mail division depots. The company plans to further streamline the maintenance and upgrading of devices by adding software distribution and device support via Remote MasterMind in the future.